Based on its extensive experience in metal material failure analysis, MTT possesses a comprehensive analytical platform and, leveraging a vast and complete failure case database together with a team of seasoned experts, provides holistic, precise, and efficient solutions ranging from diagnosing failure phenomena to in-depth root cause analysis and recommendations for preventive countermeasures.

With the rapid advancement of science, technology, and industrial production, the quality requirements for mechanical components are becoming increasingly stringent. Although the material quality and precision of components have been significantly improved, premature failures of mechanical parts used across various industries still occur from time to time. Such failures not only cause unplanned equipment downtime and costly replacements but may also lead to catastrophic safety incidents and severe environmental risks, while triggering complex liability disputes among designers, manufacturers, users, and regulatory authorities. Failure analysis is essential to identify the causes of failure, propose effective corrective measures, and prevent similar incidents from recurring, thereby ensuring the safe operation of engineering systems.

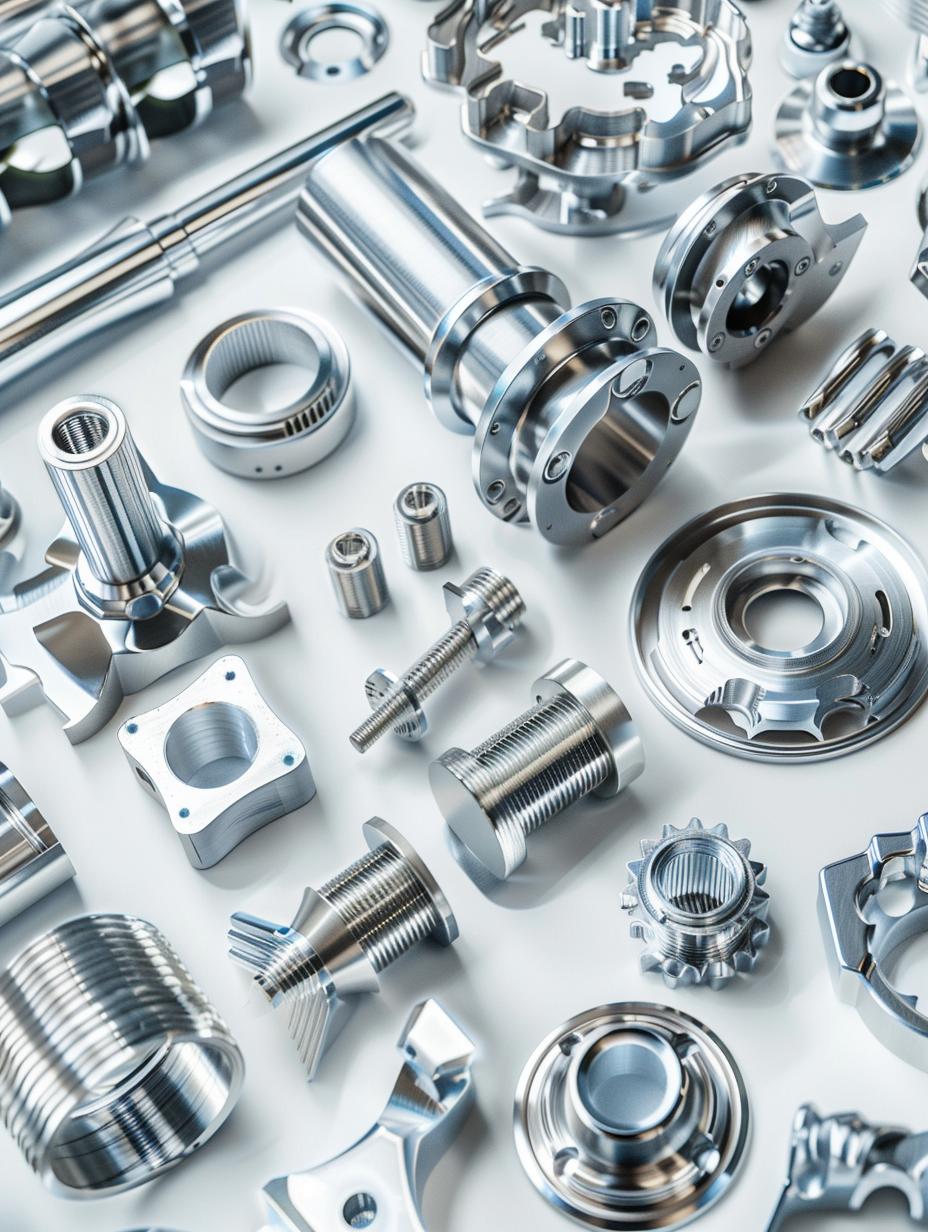

Automotive components, precision parts, mold manufacturing, casting, forging, welding, heat treatment, surface protection, and other metal-related industries.

1. Reduce and prevent the recurrence of similar product failures, minimize economic losses, and improve product quality.

2. Provide reliable scientific and technical evidence for adjudicating accident liability and establishing product quality standards.

| Common Failure Modes

1. Deformation Failure: Elastic deformation; plastic deformation; creep; stress relaxation.

2. Fracture Failure: Ductile fracture; brittle fracture (including intergranular fracture and cleavage fracture); fatigue fracture.

3. Corrosion Failure: Uniform corrosion; pitting corrosion (including perforation); crevice corrosion; localized corrosion; intergranular corrosion; galvanic corrosion; hydrogen corrosion; stress corrosion cracking; corrosion fatigue; multiphase corrosion; oxidation; sulfide corrosion; electrochemical corrosion; acidic compound corrosion.

4. Wear Failure: Abrasive wear; adhesive wear; erosive wear; fretting wear; corrosive wear; fatigue wear; erosion.

5. Surface Failure: Surface discoloration, coating delamination, blistering.

1. Failures caused by improper design: unreasonable structure or geometry, the presence of notches, small-radius fillets, and transition zones of different shapes that create high-stress areas. Failures due to poor design are relatively common. In summary, overloads in design, stress concentration, inappropriate structural selection, insufficient safety factors (in pursuit of lightweight and high speed), and improper fits can all lead to the failure of components and equipment. When analyzing failures caused by design, particular attention must be paid to the following: failure to conduct reliable stress calculations for complex components; failure to account for the types and magnitudes of abnormal service loads that components may encounter; or even, for components with accurately determined service loads and stress analysis, relying solely on static load-bearing data such as tensile strength and yield strength while neglecting failure mechanisms such as brittle fracture, low-cycle fatigue, stress corrosion, and corrosion fatigue. Such oversights can result in serious design errors.

2. Improper material selection and material defects: The selection of materials for metallic equipment and components must follow the principles of serviceability, manufacturability, and cost-effectiveness, with serviceability as the primary consideration. For components used in specific environments, foreseeable failure modes must be taken into account to ensure sufficient resistance to failure. For example, to prevent yielding deformation or fracture in ductile materials, materials with adequate tensile strength and yield strength should be chosen. However, in environments prone to brittle fracture, fatigue, or stress corrosion cracking, selecting high-strength materials often proves counterproductive. Within the framework of meeting service performance requirements, structural materials must also possess good manufacturability to ensure proper forming of the component. On the premise of ensuring the service performance and manufacturability requirements of a component, economic considerations must also be taken into account.

3. Unreasonable manufacturing processes: Metal equipment and its components often undergo a series of manufacturing processes, including machining (turning, milling, planing, grinding, drilling, etc.), hot and cold forming (stamping, pressing, rolling, bending, etc.), welding, and assembly. If process specifications are inadequately or improperly formulated, metal equipment or components are likely to retain various types of defects during these forming and processing operations. For instance, machining may commonly produce defects such as excessively small fillets, sharp chamfers, cracks, or scratches; hot and cold forming may result in surface unevenness, lack of straightness, lack of roundness, and cracks; welding may introduce surface defects such as undercut, concave welds, or excessive weld height, as well as welding cracks and internal defects including lack of fusion, porosity, or slag inclusions. The heat-affected zone of welding, due to exposure to different temperatures during the process, may undergo varying structural transformations, potentially leading to embrittlement and cracking. Assembly errors such as misalignment, eccentricity, improper centering, or forced fitting can also leave significant residual stresses. All these defects, if exceeding acceptable limits, can result in premature failure of components and equipment.

4. Improper operation and inadequate maintenance: Improper operation is one of the major causes of metal equipment failure. Unsafe practices include violations of operating procedures, overloading, exceeding temperature limits, or overspeeding; lack of experience or misjudgment; ignorance and insufficient training; as well as subjective assumptions, weak sense of responsibility, and carelessness.

1. Main defects in cast products: segregation, porosity, shrinkage cavities and shrinkage porosity, inclusions, cracks, cold shuts, and other defects.

2. Defects in metal processing and forming: hot cracks and cold cracks, heat-treatment cracks, overheating and burning, foreign matter intrusion, corrosion, coarse Widmanstatten structure, reticulated carbides and banded structure, decarburization of the steel surface layer, folds, and delamination.

1. Visual Observation: Identify the failure mode, and for fractures, determine the main crack.

Equipment used: ultra-depth-of-field microscope.

When fracture pieces exhibit both ductile and brittle fractures, brittle fracture generally occurs first, followed by ductile fracture.

When fracture pieces exhibit both brittle fracture and fatigue fracture, the fatigue fracture is usually the initiating fracture.

When two or more fatigue fractures are present, low-stress fatigue fractures occur earlier, while high-stress fatigue fractures occur later.

1) Branching method: branch cracks are regarded as secondary cracks, while converging cracks are identified as the primary crack .

2) T-type method: under normal conditions, transverse crack A is the one that initiates first. When crack A prevents crack B from propagating, or when the propagation of crack B is hindered by crack A, then crack A is identified as the primary crack, and crack B as the secondary crack.

3) Deformation method: the area with greater deformation is designated as the primary crack, while other areas are considered secondary cracks .

4) Oxidation method: the fracture origin is identified at the location exhibiting the most severe oxidation .

5) Fatigue crack length method: when two or more fatigue fractures are present, the low-stress fatigue fracture tends to have a longer fatigue crack, with denser fatigue striations or arcs, and is therefore designated as the primary crack or main fracture surface (Figure 6).

2. Microscopic Observation: observe the fracture surface morphology to determine the fracture mode.

Equipment used: scanning electron microscope (SEM).

3. Metallographic Observation: examine the metallographic structure and measure defect dimensions.

Equipment used: metallographic microscope.

4. X-ray radiography: for areas that cannot be inspected by visual examination, such as vias in PCBs or other internal defects, use an X-ray imaging system for inspection.

Equipment used: X-ray system.

5. Composition Analysis:

EDS spectrum analysis: rapid qualitative identification of elements on the analyzed surface. Equipment used: scanning electron microscope (SEM) + energy-dispersive spectrometer (EDS).

FTIR infrared analysis: analysis of foreign matter, particularly organic substances. Equipment used: Fourier transform infrared microscope spectrometer.

ICP-OES analysis: accurate quantitative identification of metal grades. Equipment used: inductively coupled plasma optical emission spectrometer (ICP-OES).

6. Phase Analysis:

Equipment used: X-ray diffractometer (XRD).

7. X-ray Photoelectron Spectroscopy (XPS)

XPS, short for X-ray Photoelectron Spectroscopy, is a method that uses an electron spectrometer to measure the energy distribution of photoelectrons and Auger electrons emitted from a sample surface under X-ray photon irradiation.

1) Surface element qualitative analysis and quantification (Li–U), with a detection limit of 0.1 at%, capable of detecting all elements in the periodic table except hydrogen and helium.

2) Ability to observe chemical shifts, which are related to atomic oxidation states, atomic charges, and functional groups. Chemical shift information forms the foundation of using XPS for atomic structure analysis and chemical bond studies.

3) Depth profiling of elemental distribution.

4) Full spectrum analysis, generally used to determine whether specific elements are present in the sample. In more extreme cases, for a sample whose chemical composition is completely unknown, XPS full-spectrum analysis can be used to determine which elements are present in the sample (excluding H and He).

Spectrum interpretation: The binding energy values of O1s can be used for identification. Peaks at 529.9 eV and 532.0 eV correspond to the characteristic peaks of M—OH compounds, 530.7 eV and 531.5 eV correspond to the characteristic peaks of M—O compounds, and 533.2 eV corresponds to the characteristic peak of H₂O.

8. Electron Backscatter Diffraction (EBSD) Analysis Technique

EBSD technology utilizes backscattered electron signals generated by the interaction of an electron beam with a sample, and by analyzing these signals, crystallographic information of the material can be obtained.

Applicable projects include: 1) texture and misorientation analysis; 2) analysis of grain size and shape distribution; 3) analysis of grain boundaries, sub-grain boundaries, and twin boundaries; 4) analysis of strain and recrystallization; 5) phase identification and phase fraction calculation, etc.

Spectrum interpretation: The upper layer is a coarse-grained layer with an equivalent grain size greater than 20 μm, while the lower layer is a fine-grained layer with a size of 0.4–0.5 μm.

9. Mechanical Property Analysis (hardness, tensile properties, impact properties, bending properties, etc.).