· National Standard Management System

The laboratory has established a complete and strict quality management system. It strictly follows international standards such as ISO/IEC17025 for management and operation. The testing solutions can be flexibly adapted to the requirements of different market regulations to meet the testing needs of customers in different market environments.

· Authoritative Qualification Certification

It has obtained a number of authoritative qualification certifications, such as CNAS accreditation and CMA qualification, providing high-quality services for customers in all aspects.

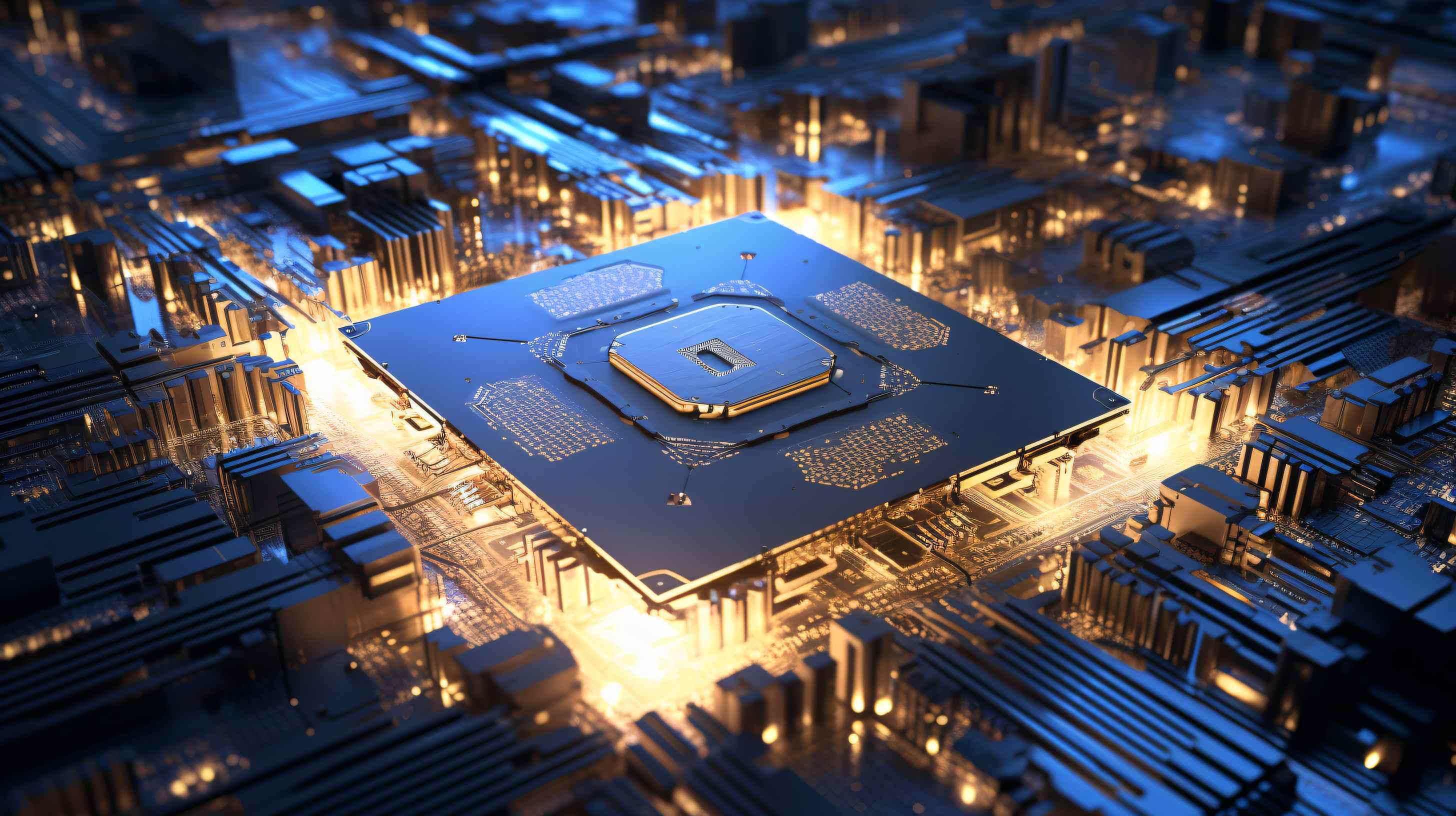

· Industrial-Grade Customized Services

It constructs a closed-loop service system of "demand research - solution design - dynamic adjustment", and provides in-depth "industrial hospital"-style testing solutions according to the characteristics of semiconductor products, precisely matching the special needs of each stage of R&D/production.

· Full-Chain Cost Reduction and Efficiency Enhancement

By leveraging failure analysis to optimize process yield, this approach simultaneously achieves three core objectives: improving product quality, shortening time-to-market, and controlling R&D costs.

· Multidisciplinary Integrated Team

MTT is staffed with numerous senior technical experts and has carefully built elite teams across multiple fields, comprehensively enhancing and refining technical capabilities to deliver outstanding technical services to its clients.

· Deep Industry Expertise

The core members have more than 10 years of experience in the testing industry, participate in major national scientific research projects and the formulation of IPC/EC/SAC international standards, ensuring both technical authority and industry foresight.

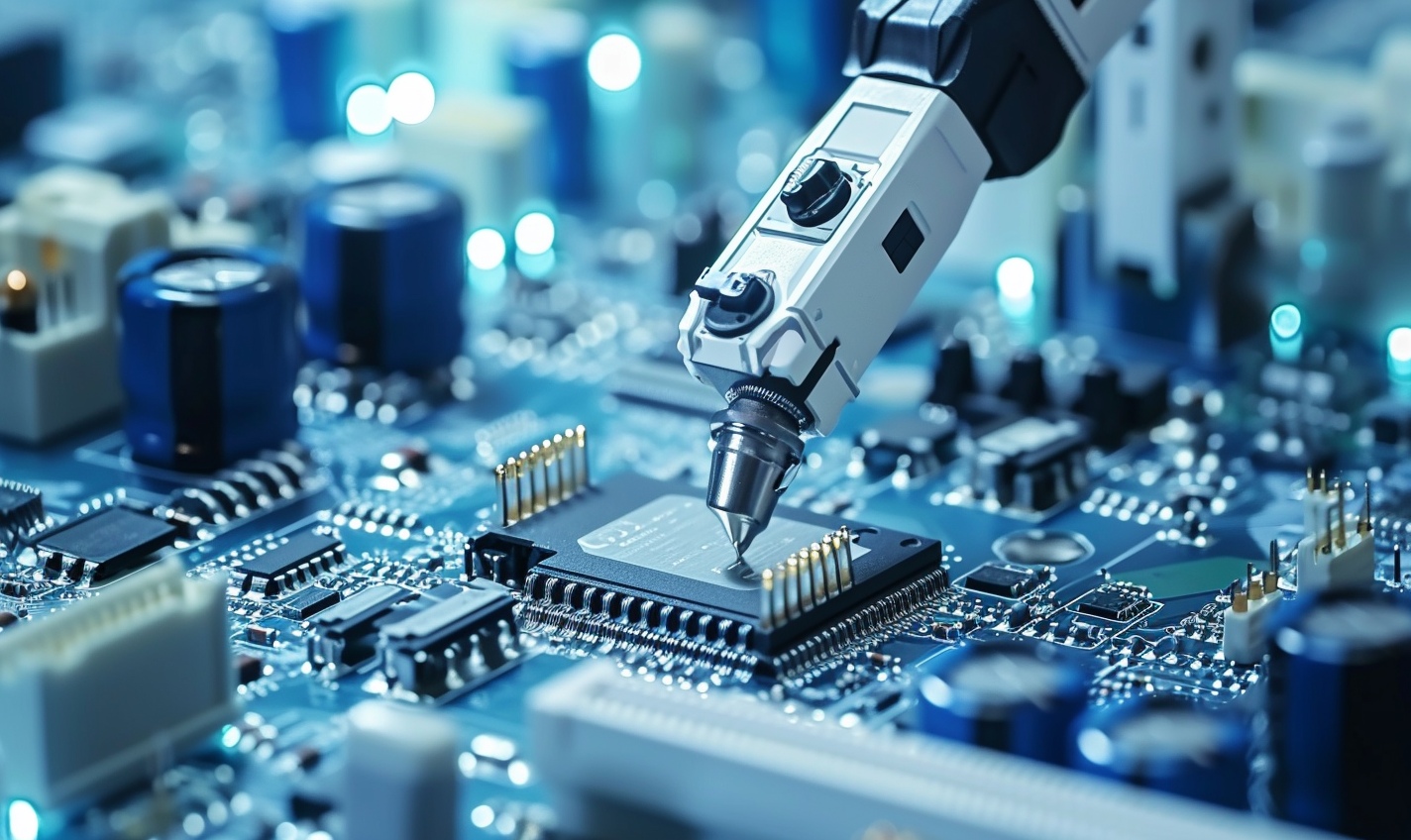

· Precision Insight through Advanced Equipment:

Equipped with internationally advanced testing instruments and apparatus, the laboratory is capable of conducting comprehensive and accurate testing and analysis of a wide range of materials, ensuring the reliability and precision of results.

· Continuous Iteration and Technological Upgrading:

Continuous investment is being made in technological research and development, with active exploration of new testing technologies and methods to meet the ever-evolving demands of the automotive industry, thereby maintaining a leading position in technological innovation within the sector.