An Ion Milling Instrument, commonly referred to in the industry as a Cross-Section Polisher (CP), is a sample preparation method free of contamination and mechanical stress.

| Project Overview

An Ion Milling Instrument, commonly referred to in the industry as a Cross-Section Polisher (CP), is a sample preparation method free of contamination and mechanical stress. Samples that cannot be prepared using conventional sectioning methods can all be processed with an ion milling system. This technique is suitable for handling soft materials, ultra-hard alloys, brittle materials, soft–hard composite materials, and porous materials, such as colloids, paper,

hard alloys, ceramics, semiconductors, glass, and polymer materials.

| Testing Principle

After argon gas is ionized, it is accelerated by an electric field to strike the sample surface, generating microscopic vibrations, impacts, or breakdown explosions that damage the surface structure, causing fragments to detach and thereby achieving delayering or cutting effects. By adjusting parameters such as accelerating voltage, ion beam current, and incident angle, the grinding speed and extent of sample damage can be controlled, ensuring optimal observation results.

| Typical Case 1

Lithium battery electrode sheets are highly reactive with water and oxygen (and may even ignite), thus requiring sample preparation under dry or vacuum conditions. Since the sintered lithium material on metal foils easily detaches or pulverizes, mechanical grinding methods are unsuitable, whereas ion milling provides perfect sample preparation.

| Typical Case 2

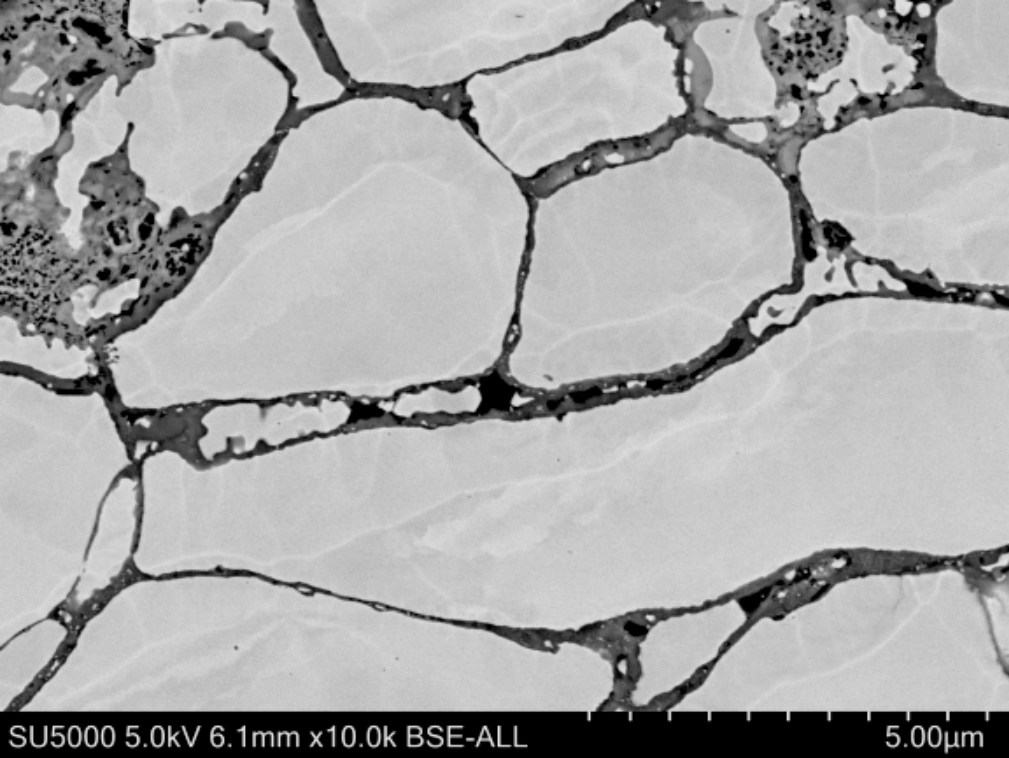

Magnetic core samples are characterized by high hardness, wear resistance, fragility, and porous structures, while the polymer binder has low hardness. This makes them soft–hard composite materials, and mechanical grinding often results in problems such as residual scratches, foreign matter filling pores, or stress-induced fractures. By employing ion milling, the pore structure and magnetic particle coating layers can be preserved completely, along with other critical information.

| Typical Case 3

For miniature PCB blind via structures exhibiting abnormally high impedance, initial suspicion suggested contamination at the via bottom. Conventional slicing methods could not confirm the presence or type of contamination. Therefore, ion milling was employed for sample preparation, preserving the complete morphology of foreign substances (including porous structures) as well as their elemental composition.

| Typical Case 4

In shale samples, mechanical grinding (left image) caused severe deformation, making it impossible to observe internal structural details. In contrast, ion milling (right image) preserved the internal structure intact, clearly revealing the detailed morphology.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.