The performance requirements for polymer materials continue to rise, while differences in understanding of high-demand products and processes between customers and suppliers often lead to frequent failures such as fracture, cracking, corrosion, and discoloration. These failures frequently cause disputes over responsibility and result in significant economic losses.

Leveraging extensive expertise in polymer failure analysis, a comprehensive hardware platform, a large-scale case database, and a team of seasoned experts, MTT provides precise, efficient, end-to-end failure analysis solutions.

With the advancement of production and scientific technology, increasingly diverse requirements are being placed on polymer materials. Overall, the future development trend for polymer material technology lies in achieving high performance, advanced functionality, compositization, intelligence, and eco-friendliness. Due to the entirely new technical requirements and the increasingly stringent demands on products, coupled with varying levels of understanding of such high-requirement products and processes among customers, polymer materials frequently experience failures such as fracture, cracking, corrosion, and discoloration. These recurring failures often lead to disputes over responsibility between suppliers and users, resulting in severe economic losses. Consequently, an increasing number of enterprises and organizations now place entirely new requirements on polymer material failure analysis. Instead of relying on traditional measures such as direct replacement, they seek to identify the root causes and mechanisms of failure through systematic failure analysis, thereby improving product quality, advancing process optimization, and providing evidence for responsibility arbitration.

Based on their applications, polymer materials are categorized as plastics, rubbers, adhesives, coatings, fibers, and functional polymers. During storage, transportation, assembly, reliability testing, or usage, they may lose their original appearance or functional performance due to external environmental factors or intrinsic structural issues, thus limiting the overall service life of the product. Identifying the causes and mechanisms of polymer material failure provides a scientific basis for improving product quality, optimizing manufacturing processes, and clarifying accountability.

Polymer Material Manufacturers: Investigate the potential causes of product failure across the stages of design, production, processing, storage, and transportation, thoroughly analyzing the mechanisms of failure. This provides critical support for enhancing product yield rates and optimizing manufacturing processes.

Assembly Plants: Responsibility arbitration; improvement of assembly and production processes; assistance in the quality inspection of incoming materials from suppliers.

Distributors or Agents: Provide strong evidence for quality responsibility and ensure fair determination of liability.

End-Product Users: Improve product processes and reliability, thereby enhancing the core competitiveness of the product.

Service Targets: Plastic parts, sealing rings, adhesives, coatings, and other polymer-based materials of various types.

1) Identify the root causes of polymer material failures and effectively propose improvements in processes and product design.

2) Provide recommendations for product and process optimization to improve yield, reliability, and competitiveness.

3) Clearly determine responsibility for product failures, providing a solid basis for judicial arbitration.

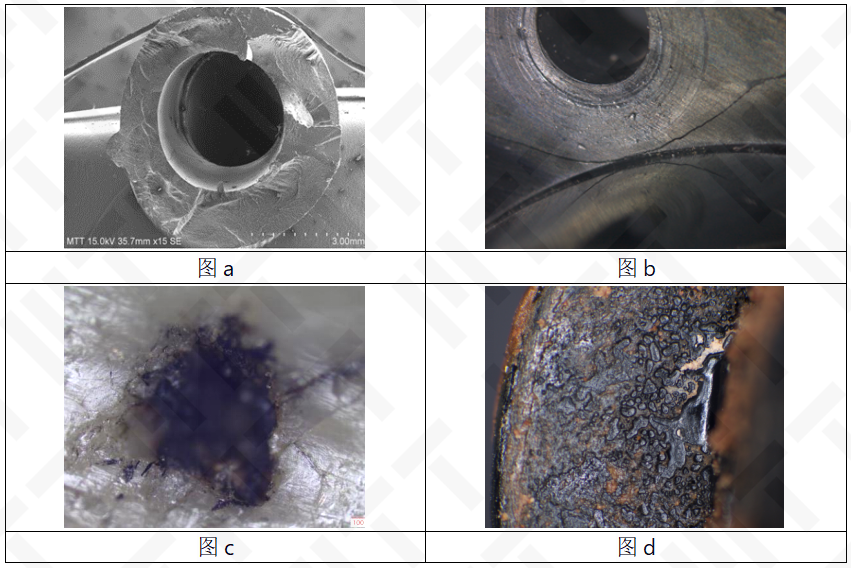

Failures include fracture, cracking, corrosion, delamination, blistering, coating detachment, discoloration, dielectric breakdown, frosting, and liquefaction failures.

| Common Failure Analysis Techniques

Analysis Items: Morphological observation, material identification, compositional analysis, thermal performance analysis, molecular weight analysis, stress analysis, physical property analysis, and simulation verification.