Accurately evaluate the surface treatment effect of components by measuring the depth of carburizing/nitriding/hardening layers. By detecting the penetration depth and microstructure changes after carburizing, nitriding, or hardening treatment, it is possible to determine whether the process meets the standards and ensure that the component has the expected wear resistance, fatigue resistance, and other properties.

Accurately evaluate the surface treatment effect of components by measuring the depth of carburizing/nitriding/hardening layers. By detecting the penetration depth and microstructure changes after carburizing, nitriding, or hardening treatment, it is possible to determine whether the process meets the standards and ensure that the component has the expected wear resistance, fatigue resistance, and other properties.

This is crucial for ensuring the quality of mechanical parts and extending their service life. At the same time, it helps enterprises optimize process parameters, control production costs, and provide key data support for failure analysis, which is the core link to enhance product competitiveness.

| Test Objective

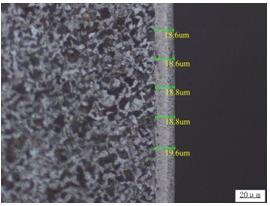

Check the penetration depth and microstructure changes of components after surface carburizing, nitriding or hardening treatment.

| Service Products / Fields

Steel parts subjected to surface treatments such as carburizing, nitriding, decarburizing, and carbonitriding, as well as steel parts after induction hardening.

| Testing Standards

|

ISO 3887-2003 |

钢.脱碳层的测定 Steel-Determination of decarburized layer |

|

GB/T 224-2008 |

钢的脱碳层深度测定法 Method for determining the depth of the decarburized layer in steel |

|

QC/T 29018-1991 |

汽车碳氮共渗齿轮金相检验 Metallographic inspection of carbonitrided gears for automobiles |

|

ASTM E1077-2001 (2005) |

评估钢样品脱碳层深度的试验方法 Test method for evaluating the depth of the decarburized layer in steel samples |

|

ISO 2639-2002 |

钢.渗碳层和硬化层深度的测定和检验 Steel-Determination and inspection of the depth of carburized and hardened layers |

|

GB/T 11354-2005 |

钢铁零件 渗氮层深度测定和金相组织检验 Determination of the depth of the nitrided layer and metallographic structure inspection of iron and steel parts |

|

GB/T 9451-2005 |

钢件薄表面总硬化层深度或有效硬化层深度的测定 Determination of the total hardened layer depth or effective hardened layer depth of thin surfaces of steel parts |

|

GB/T 5617-2005 |

钢的感应淬火或火焰淬火后有效硬化层深度的测定 Determination of the effective hardened layer depth after induction hardening or flame hardening of steel |

|

GB/T 9450-2005 |

钢件渗碳淬火硬化层深度的测定和校核钢件渗碳淬火硬化层深度的测定和校核 Determination and verification of the hardened layer depth of carburized and quenched steel parts. Determination and verification of the hardened layer depth of carburized and quenched steel parts. |

|

GB/T 9095-2008 (ISO 4507-2000) |

烧结铁基材料渗碳或碳氮共渗硬化层深度的测定及其验证 Determination and verification of the hardened layer depth of carburized or carbonitrided sintered iron-based materials |

| Typical Images

|

|

|

|

Inspection of the nitrided layer depth |

Inspection of the carburized layer depth |

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.