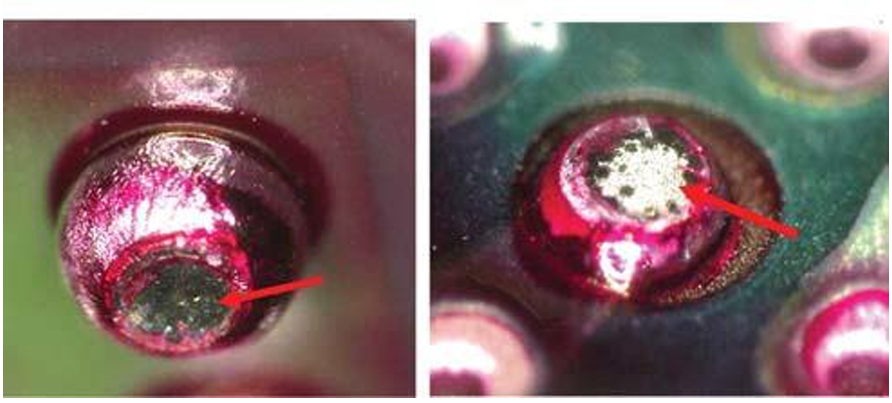

After the PCBA is cleaned, dipped, and baked, the components are separated from the PCB. The cracks and solder joint interfaces with cold soldering will be covered by the dye.

| Project Overview

After the PCBA is cleaned, dipped, and baked, the components are separated from the PCB. The cracks and solder joint interfaces with cold soldering will be covered by the dye. By observing the dyeing conditions on both sides of the components and the PCB, the quality or integrity of the solder joints can be judged. The test samples are SMT components soldered to the board. Generally, this method is used for ball grid arrays (BGA) to evaluate the quality/integrity of their solder joints. However, it can also be used for other SMT components, such as bottom terminal components (BTC) and connectors.

| Test Objective

Through the dye penetrant test, the assembly soldering process parameters and the quality/integrity of the solder joints can be confirmed.

| Testing Standards

IPC-TM-650 2.4.53 Dye and pull test method

| Service Products / Fields

Products involved: BGA or BTC devices on the PCBA

Related fields: Consumer electronics, automotive electronics, aerospace electronic products

| Testing Principle

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.