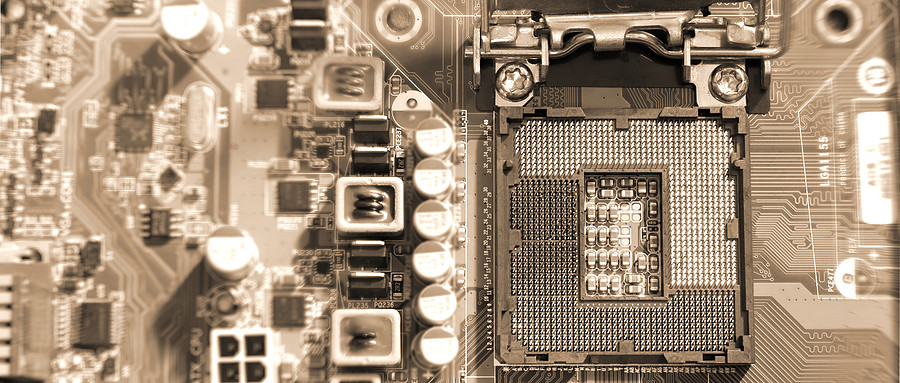

With the continuous progress of miniaturization and high integration of electronic products, the indispensable and important mounting process is also widely used. However, mounted components are prone to breakage under the influence of PCB deformation.

| Project Background

With the continuous progress of miniaturization and high integration of electronic products, the indispensable and important mounting process is also widely used. However, mounted components are prone to breakage under the influence of PCB deformation. Especially with the implementation of the lead-free process directive and the increase in soldering temperature, the PCB stress during the assembly and soldering process is increased, which doubles the fragility of the solder joints and increases the risk of solder cracks. Some solder cracks do not cause the immediate failure of the component's function. Therefore, a series of subsequent tests such as functional tests will not detect the defects. The function may fail during product assembly or within the warranty period after leaving the factory, thus increasing the economic cost of the enterprise and affecting the promotion of the product brand.

| Project Overview

First, analyze the PCB according to the operation process and select the test points. Second, prepare the PCB circuit board, grind and clean it. Then select a suitable strain gauge for pasting, label the pasted strain gauges and number them, and make preparations for strain measurement. Third, connect the strain gauge sensor to the data acquisition device, run the test program, and collect strain data.

| Test Objective

1. PCB stress-strain test or board-splitting stress;

2. PCB stress-strain test or board-splitting stress;

3. Provide feedback basis for PCB design and panel layout.

| Testing Standards

IPC-JEDCE 9704 Printed Circuit Board Strain Testing Guide

| Service Products / Fields

Consumer electronics, automotive electronics, electronic manufacturing, PCB design and materials science, reliability engineering and failure analysis, mechanics and sensing technology, etc.

| Test Items

1. Select strain gauges;

2. Prepare the PCB board and paste the strain gauges;

3. Measure the strain;

4. Analyze and record the data.

| MTT Advantages

1. Professional Team: Equipped with a number of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.