The laboratory has established a comprehensive and stringent quality management system, strictly adhering to international standards in its management and operations. Its testing programs are flexibly adapted to different regulatory requirements across global markets, effectively meeting diverse customer testing needs.

It has obtained multiple certifications from authoritative domestic and international organizations, as well as recognition from leading automotive OEMs. The testing reports and results carry strong credibility within the industry.

Establishing a closed-loop service system of “demand research–solution design–dynamic adjustment,” tailored to the characteristics of automotive electronic products, delivers an “industrial hospital”-style in-depth testing program that precisely matches the special requirements across different stages of R&D and production.

With years of accumulated testing service experience in the automotive sector, the company has gained deep insight into industry standards, regulations, and development trends. This enables the delivery of testing services that meet industry and regulatory requirements, while also providing customers with professional consultation and guidance.

Long-term and stable cooperative relationships have been established with numerous well-known automotive enterprises and component suppliers. Through excellent service and strong reputation, the company has earned wide trust and recognition from its clients.

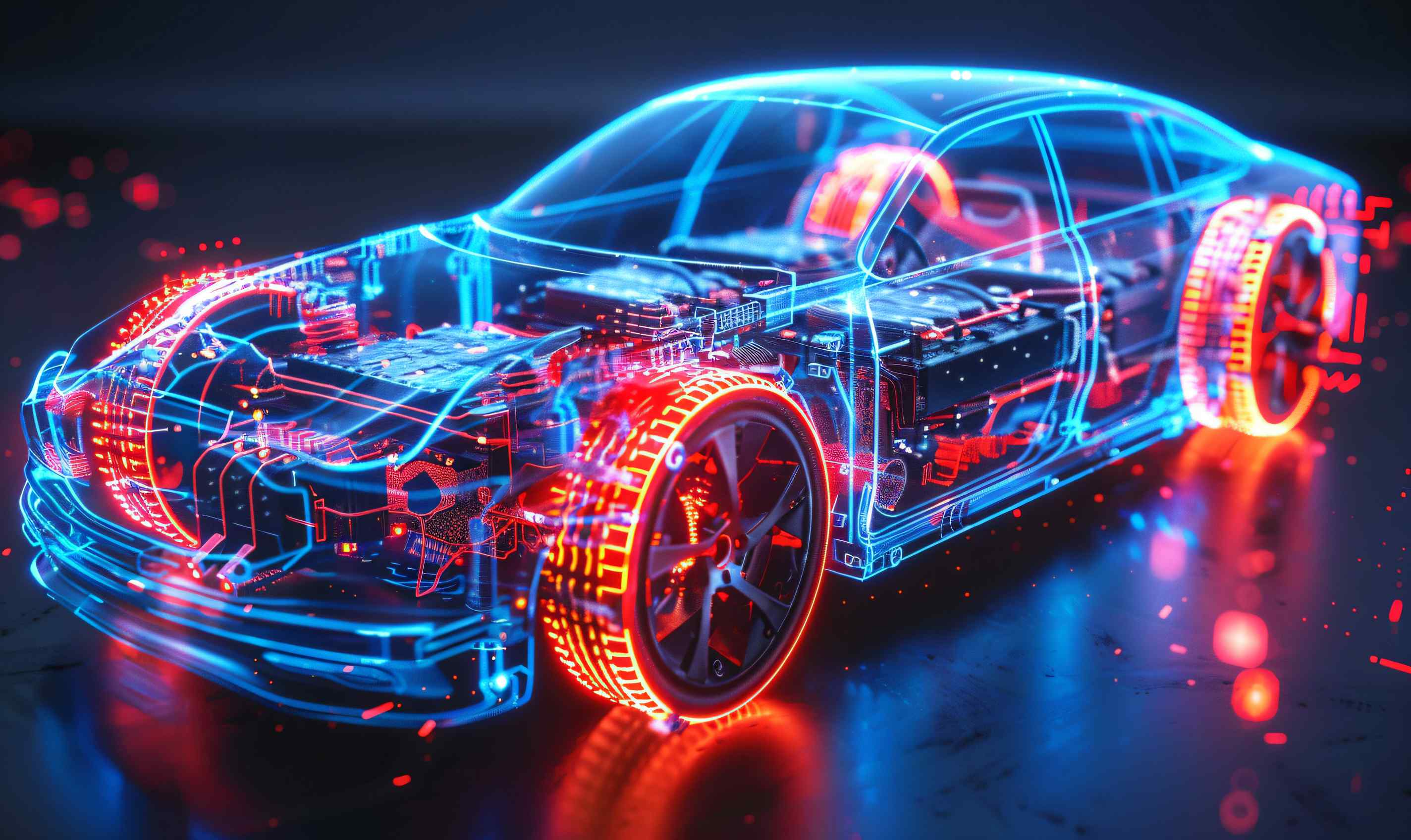

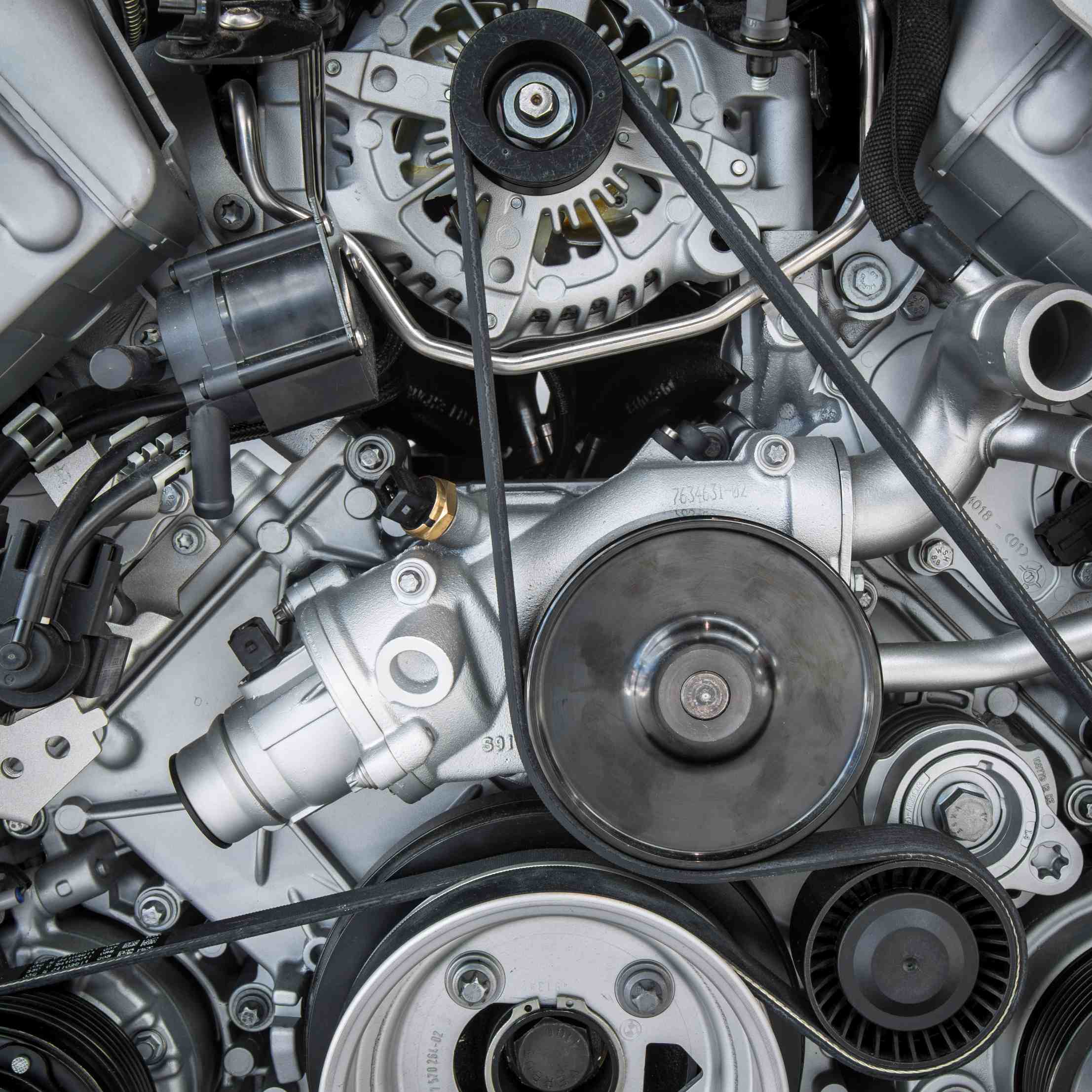

Equipped with internationally advanced testing equipment and instruments, it can comprehensively and accurately detect and analyze automotive materials, components, etc., ensuring the reliability of testing results.

Continuously increasing investment in technology research and development, actively conducting research on new detection technologies and methods to meet the constantly developing needs of the automotive industry, and maintaining a leading position in technology within the industry.