The mechanical strength (shear force) test of solder joints is a key test method for evaluating the ability of welded joints to resist damage under shear loads, and it is widely used in fields such as electronics, automotive, and aerospace.

| Project Background

The mechanical strength (shear force) test of solder joints is a key test method for evaluating the ability of welded joints to resist damage under shear loads, and it is widely used in fields such as electronics, automotive, and aerospace.

| Project Overview

Apply a shear force parallel to the welding surface to the solder joint until the solder joint breaks, and record the maximum load and failure mode. The direction of shear force is usually consistent with the plane of the bonding pad, simulating common stress types in practical applications (e.g. circuit board deformation, vibration, etc.). When failure occurs, the product structure or production process can be improved according to different fracture modes to optimize the product.

| Test Objective

1. Determine the maximum bearing capacity of the solder joint under the action of shear force.

2. Evaluate the quality of the welding process.

3. Provide reliability data for product design to ensure that the solder joint does not fail within the specified mechanical stress range.

| Testing Standards

MIL-STD-883: Reliability test methods for military electronic devices.

GJB-548 Test methods and procedures for microelectronic devices

JIS Z 3198-7 Lead-free solder test methods - Part 7: Method for determining the shear strength of chip component solder joints

| Service Products / Fields

Products involved: Printed Circuit Board Assembly (PCBA)

Fields involved: consumer electronics, automotive electronics, aerospace electronics.

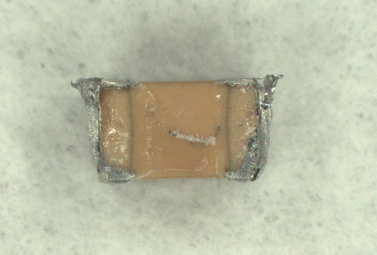

| 试验分析图

| Test Analysis Diagram

| 美信优势

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results. High accuracy and precision, strong applicability, and a solid foundation in methodology.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.