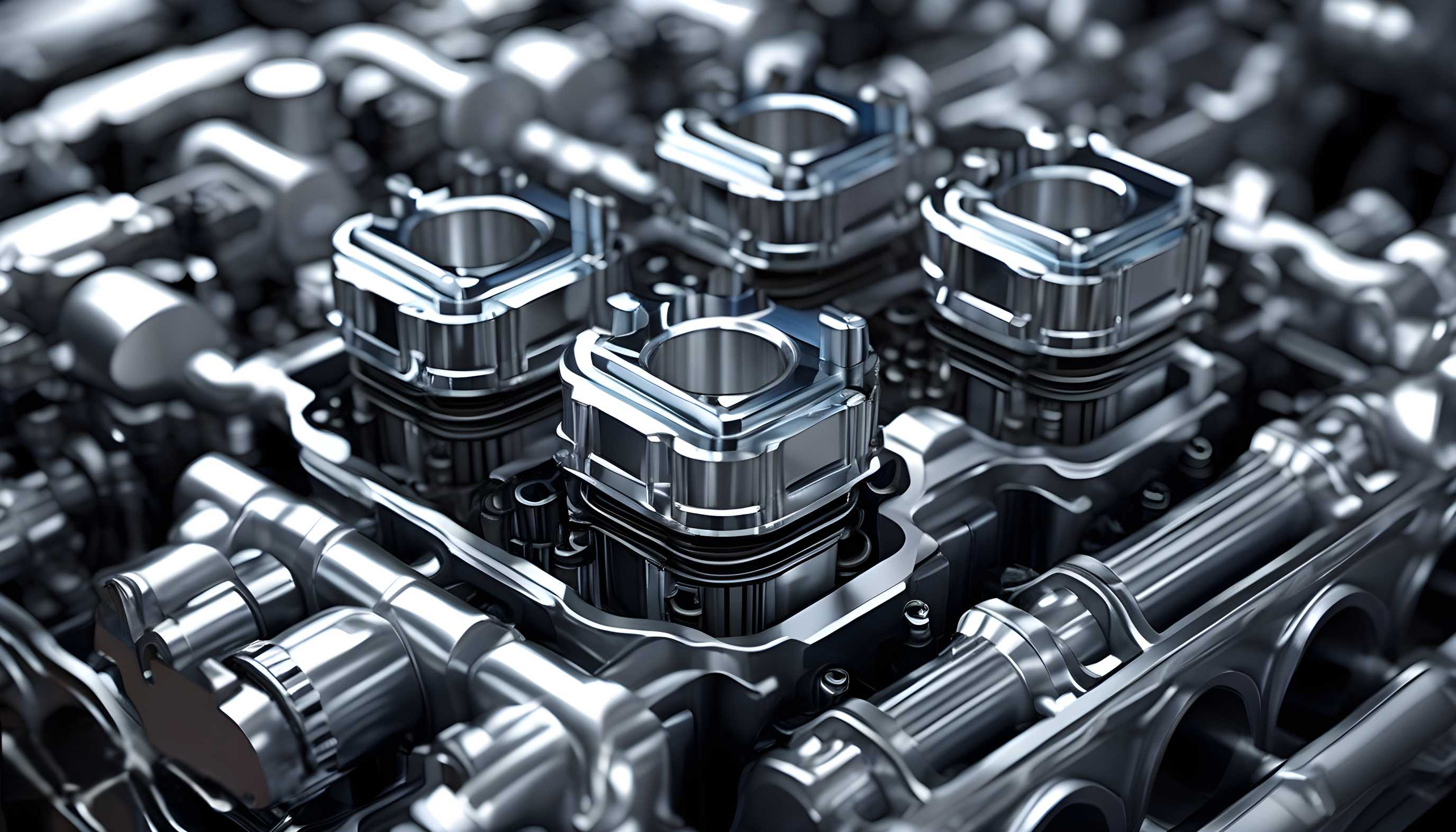

Fatigue tests simulate the repeated stretching, compression, bending, torsion, and flexing that automotive components experience under real operating conditions, and are used to evaluate the service life of the components.

| Project Overview

Fatigue is the primary mode of failure in automotive components. During actual use, due to continuous variations in load and speed, these components are subjected to cyclic alternating stresses until failure occurs. This phenomenon is known as fatigue failure, and the mileage or number of cycles at which failure occurs is referred to as fatigue life.

| Test Objective

Fatigue tests simulate the repeated stretching, compression, bending, torsion, and flexing that automotive components experience under real operating conditions, and are used to evaluate the service life of the components.

| Testing Item

|

测试项目 Test Item |

高低周疲劳试验 High- and low-cycle fatigue testing |

|

蠕变试验 Creep testing |

|

|

拉-扭复合疲劳试验 Tension-torsion combined fatigue testing |

|

|

S-N曲线的测定 Determination of the S–N curve |

|

|

负荷-位移疲劳试验 Load–displacement fatigue testing |

|

|

汽车内空调出风口耐久试验 Durability testing of automotive air-conditioning vents |

|

|

汽车内拉手耐久试验 Durability testing of automotive interior handles |

|

|

汽车内杯托耐久试验 Durability testing of automotive cup holders |

|

|

汽车内物品盒耐久试验 Durability testing of automotive storage compartments |

|

|

汽车内电子按键寿命试验 Service life testing of automotive electronic buttons |

|

|

汽车内组合开关耐久试验 Durability testing of automotive combination switches |