With the continuous development of modern industrial technology, the requirements for the environmental adaptability of products are getting higher and higher. The three-combination test has become an important means to ensure the quality and performance of products.

| Project Overview

The three-combination test, as a comprehensive environmental test method that integrates multiple environmental factors such as temperature, humidity, and vibration, is widely used in multiple fields such as electronic manufacturing, aerospace, automotive parts, and vehicle inspection. This test comprehensively evaluates the reliability, durability, and adaptability of products by simulating the working states of products under complex and changeable environmental conditions. With the continuous development of modern industrial technology, the requirements for the environmental adaptability of products are getting higher and higher. The three-combination test has become an important means to ensure the quality and performance of products.

| Test Objective

Determine the comprehensive impact of temperature, humidity, and vibration on the safety, integrity, and performance of electronic products during operation.

| Testing Standards

GB/T2423.35-2006;

GB/T2423.35-2006;

GB/T2423.36-2006;

GB/T2423.36-2006;

GB/T28046.3-2011;

GB/T28046.3-2011;

IEC/EN60068-2-50; IEC/EN60068-2-51;

IEC/EN60068-2-50; IEC/EN60068-2-51;

ISO 16750-3; GMW 3172, VW80101, etc.

| Service Products / Fields

The detection fields of the three-combination test project are extensive, including but not limited to:

Electronics manufacturing: Evaluate the working performance and reliability of electronic components, PCB/PCBA, etc. under complex environmental conditions.

Aerospace: Verify the adaptability and stability of aerospace materials and components under extreme environmental conditions to ensure flight safety.

Automotive parts and whole-vehicle testing: Evaluate the durability and reliability of automotive parts and whole vehicles under complex environmental conditions to improve the quality and performance of automotive products.

Other industries: In fields such as medical devices and semiconductor devices, the environmental adaptability and reliability of products can also be evaluated through the three-comprehensive test.

| Project Advantages

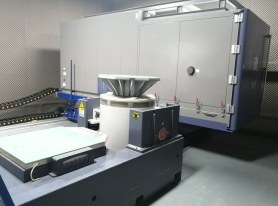

1. The temperature range can reach from -70°C to 180°C;

2. It can realize vibration + rapid temperature change, vibration + temperature-humidity comprehensive test, shock + temperature-humidity change comprehensive test.

3. A test space of 2 cubic meters can meet the test requirements of large-size samples.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.