Welding residual stress is the main cause of process defects such as deformation and cracking in welded parts. Welding deformation endangers shape and dimensional tolerances, joint installation deviations, and increases groove gaps during the manufacturing process, making the manufacturing process more difficult; Welding residual stress can cause the weld, especially the tack weld, to partially or completely break;

| Project Background

Welding residual stress is the main cause of process defects such as deformation and cracking in welded parts. Welding deformation endangers shape and dimensional tolerances, joint installation deviations, and increases groove gaps during the manufacturing process, making the manufacturing process more difficult; Welding residual stress can cause the weld, especially the tack weld, to partially or completely break; The residual stress released during the machining process can also cause unacceptable deformation of the workpiece. At the same time, welding residual stress may cause brittle fracture of the structure. Tensile residual stress will reduce fatigue strength and corrosion resistance, and compressive residual stress will reduce the stability limit. Therefore, welding residual stress has always been one of the key issues concerned by the welding industry.

| Hazards of Welding Residual Stress

I. Formation Mechanism of Welding Residual Stress

To find the right methods to control and eliminate welding residual stress, it is necessary to first understand its formation mechanism as a basis. Welding is a complex physical and chemical process. The physical phenomena involved include heat transfer, melting and solidification of metals, and phase transformation during cooling. The formation of welding residual stress is also the result of the interaction of multiple factors. Therefore, the research on its formation mechanism has also gone through a process of continuous development and improvement. The evolution process of the theoretical understanding of the generation mechanism of welding residual stress is shown in Figure 2.

Figure 2 Theoretical evolution process of welding residual stress generation mechanism

In the early 1970s, the foundation of the theory of welding residual stress and deformation was roughly laid. In the works of H.O. Okelblom and C.A. Kuzminov of the Soviet Union, a theory of residual plastic deformation under one-dimensional conditions was proposed. That is, during the welding heating process, the thermal expansion strain of the metal in the weld and the heat-affected zone is restricted by the surrounding cooler metal, thus generating compressive plastic strain. During the welding cooling process, part of this compressive plastic strain is offset by tension, but some compressive plastic strain still remains after welding, which is called residual compressive plastic strain.

The above theory of residual plastic deformation under one-dimensional conditions assumes that the weld has always been a part of the original workpiece and has undergone the entire heating and cooling process. In 2000, some scholars questioned the above theory of residual plastic deformation, believing that this theory ignores a basic fact. That is, in most cases, the weld is filled with molten metal, and it can be said that the weld cools directly from a high temperature and only experiences the cooling process. It is believed that when the weld cools from a high temperature and is restricted by the surrounding area, only tensile plastic strain will be generated. From this perspective, the principle of eliminating welding residual stress is explained. It is considered that the process of stress elimination is essentially a process of transforming tensile elastic strain into tensile plastic strain.

In 2002, some scholars, by analyzing the one-dimensional simplified models of a rod with both ends restricted and a long strip-shaped welded part, first agreed with the traditional theory of residual plastic deformation. That is, it is assumed that the weld itself undergoes the heating and cooling process, and there is residual compressive plastic strain at the weld after complete cooling. For the assumed situation where the weld is filled with metal and cools directly from a high temperature, since part of the thermal shrinkage strain is offset by the tensile plastic strain during the cooling process, there is residual thermal shrinkage strain at the weld after complete cooling. Through analysis, the residual compressive plastic strain and the residual thermal shrinkage strain are equivalent. This theory explains the phenomenon that the results of residual stress and deformation during the welding of workpieces with non-grooved welds and workpieces with grooved and filled welds are completely similar. The concept of "inherent strain" is introduced, and it is considered that welding residual stress is the result of the automatic balance of the component under the action of the inherent strain source.

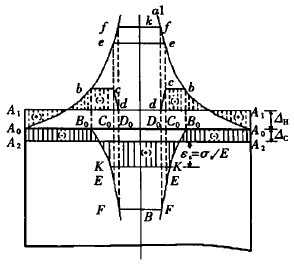

Figure 3 Stress and strain during the welding of long strips

The part B0KKB0 in the figure represents the residual compressive plastic deformation existing in the strip after it is finally completely cooled.

In 2003, some scholars questioned the aforementioned view. They believed that although the residual compressive strain and the residual shrinkage strain are equivalent in terms of causing the generation of welding residual stress, their essences are different. It is meaningful to distinguish their contributions to the formation process of welding residual stress, which has a guiding role in the research and development of new welding residual stress control technologies. Without considering the phase transformation, in addition to the welding residual stress caused by the compressive plastic deformation in the base metal described by the traditional mechanism, the restricted shrinkage of the weld metal during cooling is also an important reason for the generation of welding residual stress. This scholar believes that when the phase transformation strain is not considered, the inherent strain at the weld should be the plastic tensile strain.

Figure 4 Longitudinal stress and strain distribution during the welding of low-carbon steel

The hatched area in the lower part of the figure is the plastic tensile zone. The surfacing welding model on the plate described in the figure is only suitable for occasions such as surfacing wear-resistant layers.

In summary, there is a dispute between compressive plastic strain and tensile plastic strain regarding the residual stress at the weld. The understanding of welding residual stress is continuously deepened through agreement or questioning. In terms of the effect of its internal restraint degree, the generation mechanism of welding residual stress can be expressed as follows: The welding heat input causes the material to be locally heated unevenly, causing the weld zone to melt; while the thermal expansion of the material in the high-temperature zone adjacent to the molten pool is restricted by the surrounding materials, resulting in uneven compressive plastic deformation; during the cooling process, this part of the material that has undergone plastic deformation (such as both sides of a long weld) is restricted by the surrounding conditions and cannot shrink freely, and is stretched to varying degrees to form tensile stress; meanwhile, when the molten pool solidifies and the cooling shrinkage of the formed weld metal is blocked, corresponding tensile stress will also be generated.

| Welding residual stress control and elimination

To achieve the goal of reducing the residual stress of welded workpieces, two aspects can be considered: one is to control the generation of welding residual stress and reduce the residual stress from the source; the other is to eliminate the residual stress through methods after welding.

1. Welding residual stress control

Controlling welding residual stress means taking some appropriate measures during the manufacturing process of the welded structure to reduce the welding residual stress. Generally speaking, it can start from two aspects: design and process. When designing the welded structure, on the premise of not affecting the service performance of the structure, a design scheme that reduces and improves the welding stress should be considered as much as possible. In addition, some process measures should also be taken during the manufacturing process to minimize the welding stress. The summary of welding residual stress control methods is shown in Figure 5.

Example: Influence of welding structure and sequence on welding residual stress

Some scholars used the finite element method to analyze the influence of welding structure and welding sequence on residual stress. The finite element analysis software MSC.Marc was used to conduct numerical simulation calculation and analysis of the welding residual stress of the commonly used local reinforcement patch welding structure in construction machinery made of high-strength steel. After calculating four different structures and welding sequences, the comparative analysis results show that: structural restraint and welding sequence have an important influence on welding residual stress. The local reinforcement patch increases the structural restraint degree, resulting in an increase in welding residual stress. Welding the main structure first and then the local reinforcement patch results in the maximum welding residual stress. Therefore, appropriately designing the welding structure and welding sequence is beneficial to reducing the welding residual stress of the structure and improving the reliability of the welded structure.

Figure 6 Relationship curve between welding residual stress and radial position

Structure A has a reinforcement ring, while structure B does not; Structures 1 and 2 have different welding sequences.

2. Elimination of welding residual stress

The methods for eliminating residual stress can be divided into mechanical action methods and thermal action methods. The mechanical method uses external force to produce plastic deformation in the material to achieve the purpose of reducing residual stress. Theoretically, as long as the external force causes the whole homogeneous component to reach the yield point simultaneously, it is possible to completely eliminate the residual stress. However, in practice, due to various difficulties, it is difficult to completely eliminate the stress by this method. Eliminating residual stress by thermal action is closely related to creep and stress relaxation phenomena. When using thermal action to remove residual stress, as long as the annealing temperature and holding time are appropriate, the stress can be completely eliminated. However, at the same time, it will cause a decrease in the hardness and other mechanical properties of the material, and the structural changes caused by the thermal action are also inevitable. The summary of the methods for eliminating welding residual stress is shown in Figure 7.

Figure 7 Methods for eliminating welding residual stress

Example: Influence of post-weld heat treatment on welding residual stress

Some scholars have studied the influence of post-weld heat treatment on the residual stress of 20MnNiMo welded joints. A welding scheme and a post-weld heat treatment scheme were formulated, and the surface residual stress of the welded joints was measured and recorded by the blind-hole method. The influence of post-weld heat treatment on the distribution of the residual stress field of 20MnNiMo thick-plate welded joints was studied. The results show that stress-relieving annealing after welding can effectively reduce the welding residual stress of 20MnNiMo thick plates. The stress-relieving effect is significant, and it can well improve the distribution of the welding residual stress of 20MnNiMo.

Figure 8 Distribution diagrams of residual stress in as-welded and annealed states

In traditional methods, the scheme design and process formulation in the welding process more rely on the experience and technology of design and construction personnel. The screening of the optimal process scheme and welding parameters requires a large number of experimental works in the workshop or laboratory, which is a waste of manpower, material resources and time. With the continuous in-depth development of research in the welding field, scholars have been constantly introducing new achievements of various basic theories into the research of the welding process. As a result, many phenomena in the welding process can not only be theoretically explained in essence, but also quantitatively analyzed, simulated and theoretically predicted, which provides a basis for the welding process simulation technology. At present, the simulation technology of the welding process has become a research hotspot in the field of welding. Through computer simulation technology, the dynamic changes of the temperature field and residual stress in the welding process can be simulated, providing theoretical guidance for the control and elimination of residual stress.