Through systematic analysis, the testing of plastic encapsulated devices shifts reliability control from "remedial measures" to "preventive measures". It has irreplaceable value in ensuring product quality, reducing risk costs, and promoting technological progress. It is the core link of quality management in the high-end manufacturing field.

| Overview of Destructive Physical Analysis (DPA)

Destructive Physical Analysis (DPA) refers to a comprehensive process of inspections and analyses, both non-destructive and destructive, conducted on samples taken from production lots of electronic components. The purpose is to verify whether the design, structure, materials, and manufacturing quality of the components meet their intended use or relevant specification requirements.

DPA analysis technology can proactively identify potential defects in materials, processes, and other aspects of components. Although the precise timing of failures caused by such defects cannot be predicted, the consequences they may trigger are often severe.

| Test Objective

1. It is carried out with the objective of preventing failures, ensuring that components with obvious or latent defects are not installed and used.

2. To identify deviations and process defects that may exist during the design and manufacturing of components.

3. To evaluate and validate the quality of components supplied by vendors.

4. To provide recommendations for batch processing and propose corrective measures.

| Service Products / Fields

1. Applicable in fields with high reliability requirements, such as aviation, aerospace, and automotive electronics.

2. For components classified as key or critical parts in electronic products.

3. For components that are used in large quantities.

| Timing Nodes for Conducting DPA

|

DPA开展时间节点 Timing Nodes for Conducting DPA |

具体内容 Details |

|

1、器件选型认证 1. Device Selection and Qualification |

- 不同供应物料差异对比 - Comparison of differences between materials from different suppliers - 提前识别可靠性风险点,及时改进 - Early identification of potential reliability risk points and timely improvement - 质量排序 - Quality ranking |

|

2、生产进货检验 2. Incoming Inspection During Production |

- 供货方提供真伪保障 - Supplier provides authenticity assurance - 来料检验内部缺陷检查 - Incoming inspection to check for internal defects - 缺陷风险拦截,避免上线生产 - Defect risk interception to prevent defective parts from entering production lines |

|

3、筛选试验 3. Screening Tests |

- 器件可靠性评估 - Component reliability assessment - 功能测试ok,器件长期风险识别 - Functional tests confirmed as passed, with identification of long-term risks associated with the components - 可靠性风险拦截 - Reliability risk interception |

|

4、失效分析 4. Failure Analysis |

- 快速风险评估 - Rapid risk assessment - 替代物料评估 - Evaluation of alternative materials - 整改方案快速制定,降低维护和整改成本 - Quick formulation of corrective action plans to reduce maintenance and rectification costs |

|

序号 No. |

试验项目 Test items |

检查内容 Inspection Items |

预防的失效模式 Preventive failure modes |

|

1 |

外部目检 External visual inspection |

包封平整度、形变等等 Encapsulation flatness, deformation, etc. |

焊接不良、芯片开裂 Poor soldering, chip cracking |

|

2 |

X射线检查 X-ray inspection |

器件内部结构、引线、引线框架 Internal device structure, leads, lead frames |

结构问题、装配工艺不良 Structural issues, defective assembly processes |

|

3 |

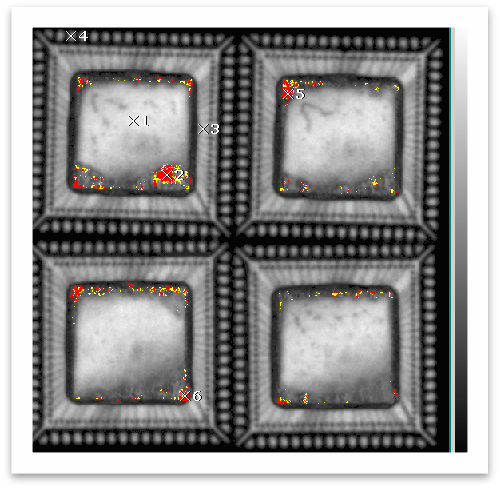

声学扫描 Acoustic scanning |

裂纹、分层、孔洞 Cracks, delamination, voids |

电化学迁移、开短路失效 Electrochemical migration, open/short circuit failures |

|

4 |

内部目检(剖切、开封) Internal visual inspection (Cross-sectioning, Decapsulation) |

芯片金属化层、钝化层、划片、引线键合、芯片安装、外来物质等等 Chip metallization layer, passivation layer, dicing, wire bonding, chip mounting, foreign materials, etc. |

加工工艺不良引入的缺陷 Defects introduced by poor manufacturing processes |

|

5 |

键合强度 Bonding strength |

内引线键合强度 Inner wire bonding strength |

互连开路、间歇失效 Interconnect open circuits and intermittent failures |

|

6 |

扫描电镜 Scanning electron microscope |

类似于“内部目检” Similar to “internal visual inspection” |

加工工艺不良引入的缺陷 Defects introduced by poor manufacturing processes |

|

7 |

钝化层完整性检查 Passivation layer integrity inspection |

钝化层破损、裂纹 Passivation layer damage and cracks |

参数漂移、功能异常 Parameter drift and functional abnormalities |

| Typical Cases

Interface delamination

Wire bond root fracture

Bond pull zero-gram point

Cracking of the chip surface passivation layer

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.