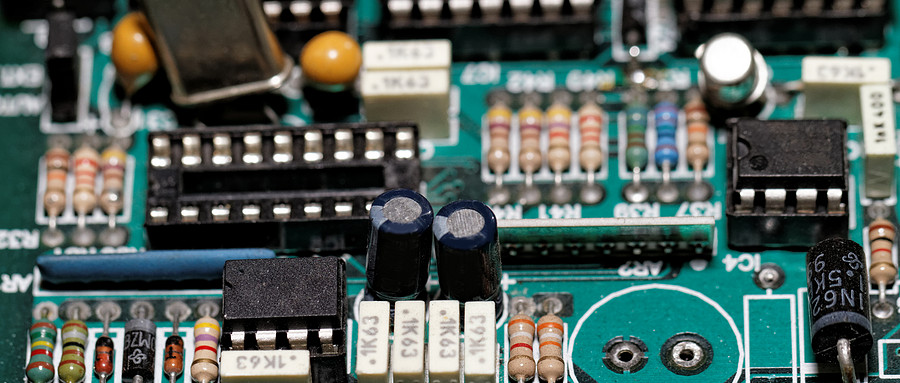

Domestic component certification is a process that verifies, through systematic testing and evaluation, whether domestically manufactured electronic components (such as chips, resistors, capacitors, sensors, etc.) meet the requirements of specific application scenarios in terms of electrical performance, environmental adaptability, and reliability.

| Project Overview

Domestic component certification is a process that verifies, through systematic testing and evaluation, whether domestically manufactured electronic components (such as chips, resistors, capacitors, sensors, etc.) meet the requirements of specific application scenarios in terms of electrical performance, environmental adaptability, and reliability.

This certification, aimed at replacing imported components, covers the entire industrial chain from materials and design to manufacturing. It confirms the technical specifications, compatibility, and long-term stability of the components through standardized testing procedures, thereby promoting the large-scale application of domestic components in critical fields.

The certification process typically includes: document review, performance testing, environmental reliability testing, and compatibility verification.

| Test Objective

1. Compliance with technical specifications: confirming that the electrical parameters (such as operating voltage, frequency, and power consumption) and physical characteristics (such as package dimensions and pin strength) of domestic components meet design requirements and industry standards.

2. Reliability verification: evaluating the risk of failure in long-term use through accelerated aging tests (such as high-temperature lifetime and temperature cycling), ensuring that the components meet the requirements of high-reliability scenarios such as military and aerospace applications.

3. Supply chain security assurance: eliminating dependence on imported components, establishing an autonomous and controllable supply chain system, and reducing “choke point” risks (such as technology blockades and trade restrictions).

4. Industrial ecosystem collaboration: promoting compatibility optimization between domestic components and downstream complete machines and systems, thereby fostering coordinated development across the entire chain of “design–manufacturing–application.”

5. Cost–benefit balance: under the premise of ensuring performance, verifying the cost-performance advantages of domestic components, and providing data support for large-scale procurement.

| Testing Standards

GJB 548C-2021, AEC-Q series.

| Service Products / Fields

Military and aerospace, information infrastructure, automotive and new energy, industrial control, consumer electronics, and the Internet of Things (IoT).

| Project Advantages

1. Visualization of Internal Defects: Break through the packaging barrier to directly observe microscopic defects of chips and interconnect structures, providing intuitive evidence for failure analysis.

2. High-Precision Operation Assurance: By applying standardized delayering processes (such as controlling chemical etching rates or laser power), avoid damage to internal devices and ensure analytical accuracy.

3. Multi-Dimensional Analysis Compatibility: After delayering, combine techniques such as SEM, energy-dispersive spectroscopy (EDS), and X-ray analysis to conduct comprehensive evaluations of material composition and defect morphology.

4. Full Lifecycle Quality Control: Applicable to R&D validation, production sampling, and failure traceability, covering quality requirements throughout the entire process from design to application.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.