Tensile test refers to a test method for determining material properties under axial tensile load. Tensile testing can determine a series of strength and plasticity indicators of materials, including elastic limit, elongation, elastic modulus, Poisson's ratio, proportional limit, area reduction, tensile strength, yield point, yield strength, and other tensile performance indicators.

| Project Background

In the fields of materials science and engineering applications, the mechanical properties of materials are the key factors determining whether they can be reliably used in specific scenarios. With the rapid development of modern industry, the requirements for mechanical performance indicators such as strength and plasticity of materials in various products have become increasingly strict. Whether it is the structural materials with high-strength and lightweight requirements in the aerospace field, the component materials that need to combine strength and toughness in the automotive manufacturing industry, or the special requirements for the flexibility and tensile resistance of materials in the electronics and electrical appliance field, it is urgent to accurately measure the mechanical properties of materials. As a classic and important testing method for the mechanical properties of materials, the tensile test can provide key data for material research and development, selection, and quality control.

| Project Overview

The tensile test refers to a test method for determining the characteristics of materials under axial tensile load. The tensile test can determine a series of strength and plasticity indicators of materials, including elastic limit, elongation, elastic modulus, Poisson's ratio, proportional limit, area reduction, tensile strength, yield point, yield strength, and other tensile performance indicators.

| Test Objective

1. Test the strength and plasticity indicators of materials

2. Tensile strength / Yield strength / Elongation after fracture / Reduction of area / Elastic modulus / Poisson's ratio / Tensile strain hardening exponent / Strain hardening

| Testing Standards

GB/T 228.1, ASTM E8/E8M, ISO 6892-1, GB/T 1040, ISO 527, ASTM D638, etc.

| Service Products / Fields

Tensile performance testing can be applied at any stage of production and can cover the entire process from the re-inspection of raw material quality to the inspection of product durability. Tests can be conducted on a wide variety of materials and products, such as metallic materials, polymer materials, composite materials, components, and structural parts.

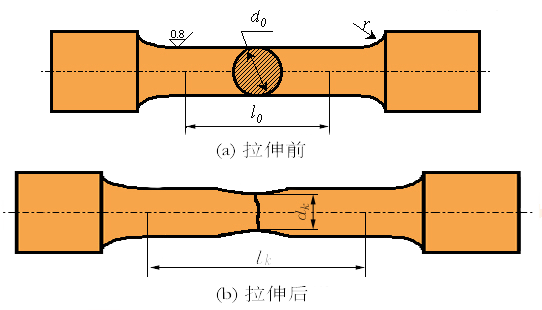

Test demonstration diagram

Typical specimen

Typical test curve

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.