Hardware white-box testing is a specialized technical program designed to conduct in-depth inspection and validation of electronic product hardware design.

| Project Overview

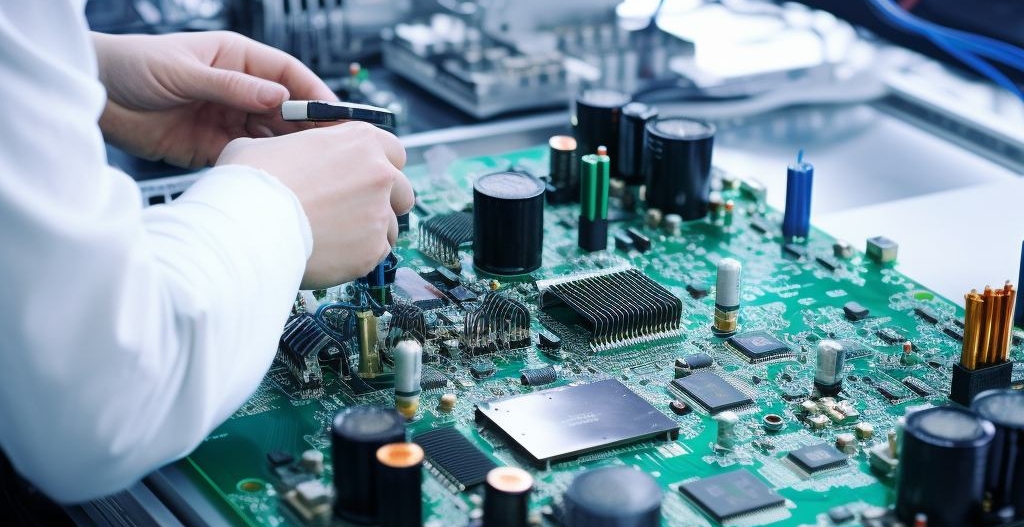

Hardware white-box testing is a specialized technical program designed to conduct in-depth inspection and validation of electronic product hardware design. This project, carried out in accordance with hardware white-box testing requirements, employs advanced instruments such as high-performance oscilloscopes and high-precision, low-ripple, low-noise power supplies. Combined with circuit principles and design specifications, it provides a comprehensive review and analysis of hardware design and signal quality to ensure compliance with functional and performance requirements while identifying potential defects or deficiencies.

The hardware white-box testing project is a highly specialized technical initiative characterized by significant application value and considerable technical challenges. Through the implementation of this project, the level and reliability of electronic product hardware design can be significantly enhanced, providing strong assurance for the sustainable development of enterprises.

| Test Objective

1. Verification that hardware design meets functional requirements: through detailed testing and analysis, ensure that the hardware design of the product satisfies functional needs and can reliably achieve the intended functions.

2. Verification that hardware design meets performance requirements: conduct comprehensive testing of hardware performance, including signal quality, response time, and stability, to ensure compliance with design specifications and performance requirements.

3. Identifying hardware design defects or deficiencies: conduct an in-depth analysis of the hardware design to locate potential flaws or shortcomings, such as unreasonable circuit layouts, signal interference, or inappropriate component selection, and propose improvement recommendations.

| Testing Standards

The hardware white-box testing project adheres to a series of stringent testing standards, including but not limited to:

GJB 548C-2021 Test methods and procedures for microelectronic devices

GB/T 5226.1-2019 Electrical safety of machinery—Electrical equipment of machines

GB/T 16855.1-2018 Safety of machinery - Safety-related parts of control systems

GJB 299C Reliability prediction handbook for electronic equipment

GJB/Z 35-1993 Derating criteria for electrical, electronic and electromechanical parts

GJB 25-91 Design guide for grounding, bonding and shielding for electronic equipments and facilities

GB/T 20438.2 Functional safety of electrical/electronic/programmable electronic safety-related systems - Part 2: Requirements for electrical/electronic/programmable electronic safety-related systems

These standards ensure the standardization of the testing process and the accuracy of the results, providing a reliable validation basis for hardware design.

| Service Products / Fields

The hardware white-box testing project is widely applied across various product domains, including telecommunications, automotive electronics, household appliances, LED drivers, switch-mode power supplies, energy storage, and photovoltaics. In these fields, the reliability and stability of hardware design are of paramount importance to the overall product performance and market competitiveness. Through hardware white-box testing, it is possible to ensure that the hardware design of the product meets all requirements, thereby enhancing product reliability and stability while reducing after-sales issues and market risks.

| Project Advantages

1. Comprehensive and in-depth inspection: hardware white-box testing conducts a thorough and detailed examination of the hardware design, covering aspects such as circuit layout, component selection, signal quality, and electromagnetic compatibility, to ensure that no critical elements of the hardware design are overlooked.

2. Precise problem localization: by employing advanced testing equipment and technical methodologies, in combination with circuit principles and design specifications, hardware white-box testing can accurately identify issues within the hardware design, providing strong support for subsequent corrective measures.

3. Improving product reliability: through in-depth analysis of hardware design to detect and rectify potential defects or deficiencies, hardware white-box testing helps enhance product reliability and stability, thereby reducing after-sales problems and market risks.

4. Enhancing market competitiveness: hardware white-box testing ensures that the product’s hardware design meets all requirements, improving overall product performance and competitiveness, and enabling enterprises to stand out in fiercely competitive markets.

5. Laying the foundation for R&D: hardware white-box testing projects provide reliable validation evidence and improvement recommendations for subsequent research and development, contributing to the enterprise’s sustained growth and innovation.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.