Destructive Physical Analysis (referred to as DPA) is a series of inspections and analyses that involve non-destructive and destructive analyses of component samples. Samples are taken from production batches of components to verify whether the design, structure, materials, and manufacturing quality of the components meet the requirements of the intended use or relevant specifications.

| Project Overview

Destructive Physical Analysis (referred to as DPA) is a series of inspections and analyses that involve non-destructive and destructive analyses of component samples. Samples are taken from production batches of components to verify whether the design, structure, materials, and manufacturing quality of the components meet the requirements of the intended use or relevant specifications. The DPA technology can identify potential defects in materials, processes, etc. of devices in advance. The time when these defects cause component failures is uncertain, but the consequences are serious.

| Test Objective

1. With the aim of preventing failures, it is necessary to prevent components with obvious or potential defects from being used in equipment.

2. Determine the deviations and process defects existing in the design and manufacturing processes of components.

3. Evaluate and verify the quality of components supplied by suppliers.

4. Put forward opinions on batch processing and improvement measures.

| Service Products / Fields

Fields with high-reliability requirements: such as aviation, aerospace, communication, medical devices, and automotive electronics;

For components classified as key or critical parts in electronic products.

For components that are used in large quantities.

| Stages of Conducting DPA

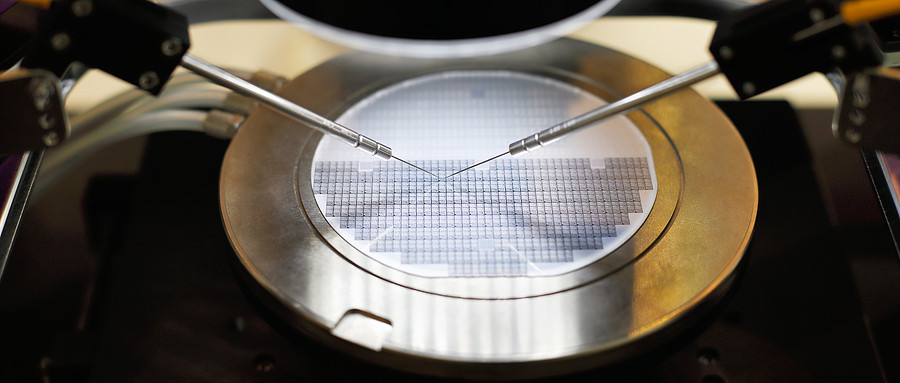

| Typical Case Pictures

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.