The AEC-Q series testing is the "quality cornerstone" of the automotive electronics industry chain. Its importance lies in ensuring driving safety, reducing full lifecycle costs, and promoting technological innovation and localization through standardization, providing reliable technical support for the era of intelligent vehicles.

| Automotive Chip Electronic Reliability Testing

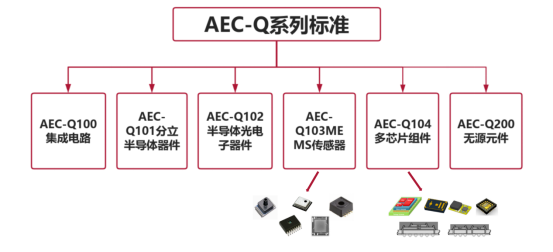

Comprehensive testing and certification services covering multiple AEC-Q series, including AEC-Q100, AEC-Q101, AEC-Q102, AEC-Q200, AEC-Q104, and AEC-Q103.

MTT can provide you with automotive chip electronic reliability testing, covering a wide range of AEC-Q series test and certification services, including AEC-Q100, AEC-Q101, AEC-Q102, AEC-Q103, AEC-Q200, and AEC-Q104.

| Project Background

The Automotive Electronics Council (AEC) established a set of verification standards by product category in order to provide a common reference framework for electronic component validation. These standards serve as the foundation for electronic component manufacturers who intend to enter the automotive market.

Within the AEC framework, it is clearly defined that there is no formal certification mechanism. Instead, the process relies on self-declaration and contractual agreements between buyers and sellers. The standards emphasize the concept of product families and highlight the importance of Statistical Process Control (SPC) in manufacturing quality management. Compared with the consumer electronics market, which mainly follows JEDEC-based validation, AEC standards are significantly more stringent.

| Automotive Chip Electronic Reliability Testing

▌ AEC-Q Verification Categories

1. AEC-Q Series Verification Categories

Categorized according to component family groups. Among these, AEC-Q103 was newly announced in 2019 to cover testing applications for MEMS-related products, thereby making the overall framework of applications more complete.

|

AEC-Q系列车用电子产品验证 AEC-Q Series Automotive Electronic Product Validation |

AEC-Q100 Integrated Circuit |

|

AEC-Q101 Discrete Semiconductors |

|

|

AEC-Q102 Photo-electronics |

|

|

AEC-Q103 MEMS |

|

|

AEC-Q104 MCM |

|

|

AEC-Q200 Passive Components |

| Product Temperature Grades

Based on the installation location of the component in the vehicle, products are divided into four temperature grades. Unlike the traditional JEDEC 47 approach, AEC defines the requirement using the ambient test temperature (Ta) instead of junction temperature (Tj). This is relatively more stringent and creates higher technical thresholds and entry barriers for manufacturers seeking validation.

|

Grade |

Ambient Operation Temperature Range |

|

0 |

-40 °C to +150 °C |

|

1 |

-40 °C to +125 °C |

|

2 |

-40 °C to +105 °C |

|

3 |

-40 °C to +85 °C |

| Comparison of AEC-Q Series and JEDEC 47

|

Description |

JEDEC 47 |

AEC Q100 |

|

Test items |

以试验项目为主 Primarily focused on test items |

自开发至试验 From development through testing |

|

Test sample size |

相对较少 Relatively fewer |

相对较多 Relatively more |

|

Test duration / cycles |

较短 Shorter |

较长(以使用寿命回推) Longer (based on lifetime back-calculation) |

|

Temperature |

采用产品Tj Uses product Tj |

采用环境Ta Uses ambient Ta |

|

Data collection |

以承认为主 Primarily for recognition |

自产品开发开始 From the start of product development |

|

Family application |

有定义 Definition provided |

定义含括范围 Definition covers scope |

|

Engineering change |

明确定义 Clearly defined |

明确定义 Clearly defined |

|

Life prediction |

说明较简易 Relatively simple explanation |

明确定计算方式 Clearly defined calculation method |

|

SPC calculation |

较少 Less |

强调应用 Emphasis on application |

|

Pb-Free consideration |

较少 Less |

纳入验证标准 Incorporated into validation standards |

|

DPA process |

未提及 Not mentioned |

纳入验证标准 Incorporated into validation standards |

|

Criteria |

较简易 Relatively simple |

允收规格明 Explicit acceptance specifications |

| MTT Advantages

1. Professional Team: Equipped with a number of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.