Whole-machine failure analysis is a specialized technical project aimed at conducting comprehensive fault investigation and analysis of complete electronic devices.

| Project Overview

Whole-machine failure analysis is a specialized technical project aimed at conducting comprehensive fault investigation and analysis of complete electronic devices. This project employs advanced instruments such as high-performance oscilloscopes and high-precision, low-ripple, low-noise power supplies, combined with circuit theory and system analysis expertise, to carry out in-depth testing and analysis of failed whole-machine samples. Its purpose is to pinpoint the failure location, analyze failure modes and mechanisms, and ultimately determine the root cause of the failure.

| Test Objective

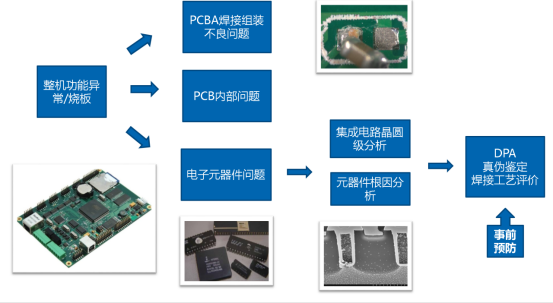

1. Pinpointing the failure location: by utilizing advanced testing equipment and technical methods, failure regions or components within the whole machine can be quickly and accurately located, whether on the circuit board or in other parts of the system.

2. Analyzing failure modes and mechanisms: by thoroughly investigating the manifestations and causes of whole-machine failures from multiple perspectives—including circuit principles, system architecture, and environmental influences—the underlying physical or chemical processes that lead to failure are revealed.

3. Identifying the root cause of failure: through a comprehensive analysis of testing data, circuit principles, and system information, the fundamental cause of the whole-machine failure is determined, thereby providing scientific evidence for subsequent corrective measures.

| Testing Standards

GJB 548C-2021

| Service Products / Fields

The whole-machine failure analysis project is widely applied across multiple product sectors, including communications, automotive electronics, household appliances, LED drivers, switch-mode power supplies, energy storage, and photovoltaic systems. In these fields, the whole machine represents the final product form of electronic equipment, where its reliability and stability are of critical importance. Once a failure occurs, it will directly impact product market performance and user satisfaction, and may even trigger serious safety incidents. Therefore, the whole-machine failure analysis project holds extremely high application value in these fields.

| Project Advantages

1. Comprehensive analysis: the whole-machine failure analysis project not only focuses on failures at the circuit board level but also covers other parts of the system, such as mechanical structures, thermal management systems, and power management, thereby delivering thorough failure analysis services.

2. Precise identification of root causes: by employing advanced testing equipment and technical methods in combination with system analysis knowledge, failures within the whole machine can be accurately pinpointed, and their root causes determined, providing strong support for subsequent corrective measures.

3. Enhancement of overall product reliability: through in-depth analysis of whole-machine failure modes and mechanisms, the project facilitates design optimization, process improvement, and system architecture enhancement, thereby improving the overall reliability and stability of the product.

4. Resolving after-sales issues: promptly and accurately identifying the root cause of whole-machine failures helps rapidly resolve after-sales problems, reduce customer complaint rates, and enhance both brand image and market competitiveness.

5. Laying the foundation for improvements: the whole-machine failure analysis project establishes a stable basis for subsequent product enhancements, production process optimization, or application expansion, thereby supporting the continuous growth and innovation of enterprises.

| MTT Advantages

1. Professional Team: Equipped with a number of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.