It is mainly used to examine the microscopic structure of metal materials and evaluate the quality of heat treatment.

| Test Objective

It is mainly used to examine the microscopic structure of metal materials and evaluate the quality of heat treatment.

| Service Products / Fields

Cast iron, steel, copper alloys, aluminum alloys, magnesium alloys, nickel alloys, titanium alloys, etc.

| Testing Standards

Steel and iron:

GB/T 13298-1991 Metal - Inspection method of microstructure

GB/T 13299-1991 Steel - Determination of microstructure

GB/T 9441-2009 Metallographic test for spheroidal graphite cast iron

GB/T 7216-2009 Metallographic test for gray cast iron

GB/T 1299-2000 Alloy tool steels

GB/T 13320-2007 Metellographic grading atlas and assessing method for steel die forgings

GB/T 11354-2005 Determination of nitrided case depth and metallographic microstructure examination for steel and iron parts

GB/T 13305-2008 Micrographic method for determining area content of the α-phases in stainless steels

GB/T 4334-2008 Corrosion of metals and alloys - Test methods for intergranular corrosion of stainless steels

GB/T 14979-1994 Eutectic carbide of steel - Micrographic method using standard diagrams

JB/T 1255-2001 Specification for heat-treatment of rolling bearing parts made from high carbon chromium steel

JB/T 9204-2008 Metallographic examination of induction hardened steel parts

JB/T 7710-2007 Determination of microstructure for the thin layer carbonitriding or carburizing elements

JB/T 7713-2007 Metallographic examination method of high-carbon high-alloy cold-work tool steel

Copper and copper alloys:

QJ 2337-1992 Metallographic test method for beryllium bronze

Magnesium and magnesium alloys:

GB/T 4296-2004 Inspection method for microstructure of wrought magnestium alloy

Aluminum and aluminum alloys:

JB/T 7946.1-1999 Metallograph of cast aluminum alloys Cast aluminum-silicon alloys - Modification

JB/T 7946.2-1999 Metallograph of cast aluminum alloys Cast aluminum-silicon alloys - Burning

JB/T 7946.3-1999 Metallograph of cast aluminum alloys Cast aluminum-silicon alloys - Pinhole

JB/T 7946.4-1999 Metallograph of cast aluminum alloys Cast aluminum-silicon alloys - Grain size

| Typical Images

|

|

|

|

45钢金相组织 Metallographic structure of 45 steel |

PMS钢金相组织 Metallographic structure of PMS steel |

|

|

|

|

314不锈钢晶间腐蚀 Intergranular corrosion of 314 stainless steel |

奥氏体双相不锈钢 Austenitic duplex stainless steel |

|

|

|

|

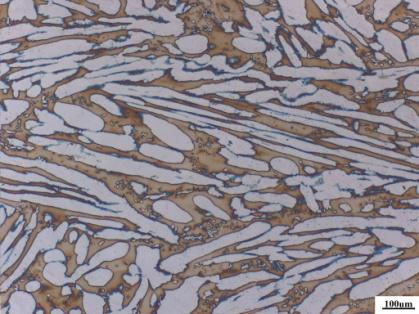

铝合金金相组织 Metallographic structure of aluminum alloy |

铜合金金相组织 Metallographic structure of copper alloy |

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.

Testing Procedure

Sampling → Cleaning → Embedding → Grinding → Polishing → Micro-etching → Observation.