The corrosion resistance test of PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly, i.e., a PCB with components soldered on it) is a key means to evaluate their ability to resist corrosion failure in environments such as humidity, salt-containing, and industrial pollution, which is directly related to the reliability and service life of electronic devices.

| Project Background

The corrosion resistance test of PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly, i.e., a PCB with components soldered on it) is a key means to evaluate their ability to resist corrosion failure in environments such as humidity, salt-containing, and industrial pollution, which is directly related to the reliability and service life of electronic devices.

| Project Overview

1. Salt spray test (the most commonly used)

It simulates the coastal and high-humidity salt-containing environment to evaluate the resistance of PCB/PCBA to chloride ion corrosion.

Test conditions:

Neutral Salt Spray (NSS): 5% sodium chloride solution, pH 6.5-7.2, temperature 35°C. The test time is usually 24h, 48h, 96h, 168h (adjusted according to product requirements).

Acetic Acid Salt Spray (ASS) or Copper-Accelerated Acetic Acid Salt Spray (CASS): A more severe acidic environment to accelerate corrosion, suitable for products with high reliability requirements (such as automotive electronics and marine equipment).

Test object:

Bare PCB: To test the corrosion resistance of copper foil and plating.

PCBA: Sensitive components (such as connectors and sensors) need to be protected from direct spraying, or only key areas (such as solder joints and edges) should be exposed.

Evaluation indicators:

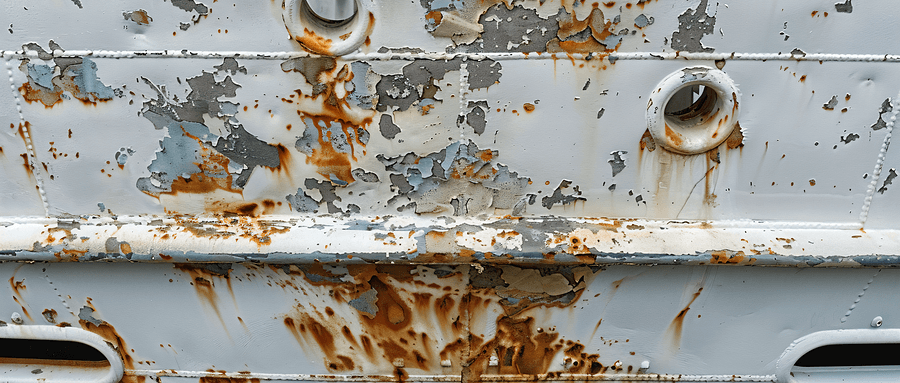

Appearance: Whether there is rust (such as patina) on pads and pins, blackening of solder joints, and peeling of plating.

Electrical performance: Test conductivity, insulation resistance (required to be ≥10⁹Ω, or according to product standards), and impedance change.

Functionality: Conduct a power-on test to check if the PCBA works properly (e.g., no short circuits, no signal interruptions).

2. Damp heat cycling test

Simulate an environment where high-temperature and high-humidity conditions alternate with normal temperature (e.g., outdoors with large day-night temperature differences) to accelerate the electrochemical corrosion caused by water vapor penetration.

Test conditions:

Temperature: Usually cycle between -40°C and 85°C, with a humidity of 90% to 95% RH. The number of cycles (e.g., 10 times, 20 times) is set according to the product's service life requirements.

Typical standards: Such as GB/T 2423.4 (Damp heat test), IPC-TM-650 2.6.3.7 (PCB damp heat test).

Evaluation indicators:

Insulation resistance: Test the change in the insulation resistance on the PCB surface or between layers (e.g., whether it is ≥10⁸Ω after the test).

Solder joint integrity: Observe through X-ray or microscope whether there are cracks or bubbles in the solder joints.

Component stability: Check whether the drift of the capacitance value of capacitors and the resistance value of resistors is within the allowable range.

3. Gas corrosion test

Simulate the impact of corrosive gases (e.g., sulfur dioxide, hydrogen sulfide, chlorine) in the industrial environment on the PCBA, which is applicable to industrial electronic equipment in industries such as chemical engineering and metallurgy.

Test conditions:

Gas type: Select according to the application scenario, such as sulfur dioxide (concentration 50-500 ppb), hydrogen sulfide (10-100 ppb), temperature 40°C, humidity 85% RH, test time 168 h-1000 h.

Standard reference: Such as ISO 16750-4 (Gas corrosion test for electronic equipment of road vehicles).

Evaluation indicators:

Corrosion degree of metal components (such as connectors, pads) (such as whether sulfides or oxides appear).

Contact resistance: Measure the change in contact resistance of connectors and switches (requirement ≤ 100 mΩ, or according to the design standard).

4. Immersion test (for specific liquid environments)

Simulate the corrosion of liquids (such as coolant, cleaner, rainwater) that PCBA may come into contact with, suitable for scenarios such as medical equipment and underwater electronics.

Test conditions: Immerse the PCBA partially or completely in a specific liquid (such as 5% sodium chloride solution, weak acid-base solution), temperature 25-50°C, time 24-168 h.

Evaluation indicators:

Whether there is a short-circuit or open-circuit after immersion.

Whether the components fail due to liquid penetration (such as corrosion of IC pins, swelling of capacitors).

5. Performance verification test of three-proof paint

If the PCBA is coated with three-proof paint (moisture-proof, salt spray-proof, and mold-proof), targeted tests on the protection effect are required:

First, conduct tests such as salt spray and damp heat tests, and then evaluate whether the three-proof paint has cracked or peeled off, and whether the underlying PCB/solder joints have been corroded.

Conduct additional tests on the chemical resistance of the three-proof paint (such as its stability after contact with alcohol and engine oil).

| Test Objective

1. Main corrosion risks

The corrosion of PCBs/PCBA mainly stems from water vapor, salts (such as chloride ions in coastal areas), industrial gases (such as sulfur dioxide and hydrogen sulfide), and electrolytes in dust in the environment. The forms of corrosion include:

Corrosion of metal plating: The copper foil, pads, and plating (such as gold plating, tin plating, and nickel plating) on the PCB surface are oxidized or electrochemically corroded, resulting in open circuits and increased resistance of the circuits.

Corrosion of solder joints: The solder joints between the component leads and the pads are corroded, which may cause cold solder joints and poor contact.

Corrosion of components: The metal leads or casings of components such as capacitors, resistors, and connectors are corroded, leading to performance failure (such as capacitor leakage and increased contact resistance of connectors).

Insulation failure: Corrosion products (such as copper rust) may cause the SIR of PCB to decrease, leading to short circuits.

2. Purpose of the test

Verify the long-term reliability of PCBs/PCBA in specific environments (such as outdoors, industrial workshops, and coastal areas).

Evaluate the effectiveness of protective measures (such as conformal coating (a three-proof paint), plating processes).

Screen materials (such as PCB substrates, plating types, component packages) and processes (such as soldering quality, coating processes).

| Testing Standards

The corrosion resistance test for PCB/PCBA shall comply with the dedicated standards of the electronics industry, with common ones including:

IPC standards: For example, 2.6.12 (salt spray test) and 2.6.3 (damp heat test) in IPC-TM-650 (PCB Test Methods Manual).

IEC standards: For example, IEC 60068-2-11 (salt spray test) and IEC 60068-2-38 (damp heat cycling test).

Automotive electronics standards: For example, ISO 16750-4 (Environmental conditions and testing for electrical and electronic equipment in road vehicles), which has more stringent requirements for salt spray and gas corrosion.

Military standards: For example, MIL-STD-883H (Test methods for microelectronic devices), which is for high-reliability scenarios (such as military and aerospace), with more extreme test conditions (such as long-term salt spray and mixed gas corrosion).

| Service Products / Fields

1. Consumer electronics: Such as mobile phones and smart home devices, need to pass the damp heat test to verify their reliability in a humid environment.

2. Automotive electronics: Such as on-board radars and ECUs, need to pass the salt spray and industrial gas corrosion tests to adapt to the harsh environments outdoors and in the engine compartment.

3. Industrial control: Such as PLCs and sensors, they need to withstand dust and corrosive gases in the factory workshop.

4. Marine electronics: Such as shipborne communication equipment, it must pass the long-term salt spray test and resist the high-salt and high-humidity environment.

5. Through targeted corrosion resistance tests, defects in the design, materials or processes of PCB/PCBA can be exposed in advance, providing data support for optimizing protective measures (such as upgrading the plating layer and increasing the thickness of the three-proof paint), and ultimately improving the environmental adaptability of electronic equipment.

| MTT Advantages

1. Professional Team: Equipped with a number of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results. Equipped with equipment such as cyclic corrosion salt spray chambers, high-and low-temperature humidity test chambers, and gas corrosion test chambers from well-known foreign brands. It complies with the operation procedures of CNAS/CMA.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.