The slicing analysis engineers at MTT have more than 10 years of testing experience in this field. They can professionally grind special devices or precision products to show the real appearance of the sliced products. With the help of microscopic equipment for microscopic observation and analysis, real results can be obtained!

| Project Overview

Sectioning technology, also known as slicing, metallographic sectioning, or micro-sectioning (English name: Cross-section, X-section), is one of the most commonly used sample preparation and analysis methods for observing the cross-sectional structure of samples.

Sectioning analysis technology is one of the most common and important analysis methods in manufacturing industries such as PCB/PCBA and components. It is usually used for quality judgment and abnormal quality analysis, inspecting the quality of circuit boards, detecting the welding quality of PCBA, finding the causes of failures and solutions, and evaluating process improvement, serving as the basis for objective inspection, research, and judgment.

| Test standards

IPC-TM 650 2.1.1, IPC-TM 650-2.2.5, IPC A 600, IPC A 610, etc.

| Service Products / Fields

Electronics industry, metal/plastic/ceramic product manufacturing, automotive parts and accessories manufacturing, communication equipment, scientific research, etc.

| Selected Sectioning Case Illustrations

|

|

|

|

|

|

| Classification of Sectioning Methods

General micro-sectioning methods can be divided into longitudinal sectioning (cutting in the direction perpendicular to the board surface) and horizontal sectioning (cutting in the direction parallel to the board surface). In addition, there are also methods for hole sectioning and oblique sectioning.

Sectioning analysis is a technical means of conducting destructive tests on samples. It is one of the most common and important analysis methods in the electronics manufacturing industry. The quality of the sample preparation in the early stage of sectioning will directly affect the accuracy of the observation and analysis of the failed parts.

| Application of Sectioning Analysis Technology in Quality Control

1. Section analysis of metal/non-metal materials

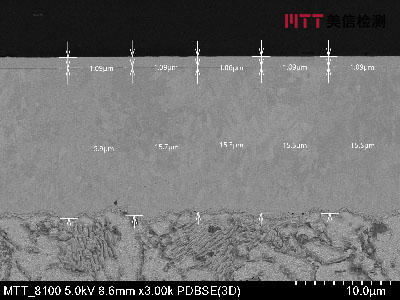

Observe the internal structure and analyze the defects of metal/non-metal materials or products, analyze the electroplating process. The sliced samples can be used to observe the morphology and analyze the composition. Observe the internal structure through the slicing method and verify the suspected abnormal cracking, voids, etc. found in the samples.

|

|

|

|

Bump foreign matter |

Crack depth |

2. Section analysis of electronic components

Use the section analysis technology and high-magnification microscope to confirm the failure phenomena of electronic components and analyze the process and raw material defects. The micro-sections prepared by the micro-sectioning technology can be used for the structural analysis of electronic components and the inspection of surface and internal defects of electronic components.

|

|

|

|

Poor soldering of ceramic capacitors |

Section of the second bonding point of LED |

3. Section analysis of printed circuit boards/assembly boards

Conduct quality determination through slicing, make a preliminary analysis of the causes of defects, and test multiple performances of printed circuit boards.

For example: resin contamination, coating cracks, hole wall delamination, solder coating conditions, inter-layer thickness, coating thickness, coating thickness inside holes, side etching, inner-layer ring width, inter-layer coincidence degree, coating quality, hole wall roughness, etc.

The micro-sections prepared by the micro-sectioning technology of printed circuit boards can be used to check the thickness of internal wires, the number of layers, the size of through-hole diameters, and observe the quality of through-holes in PCBs, as well as to check internal voids in PCBA solder joints, the bonding condition of interfaces, and evaluate the wetting quality.

|

|

|

|

False soldering/dry soldering of CPU solder balls |

False soldering/dry soldering of BGA solder balls |

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.