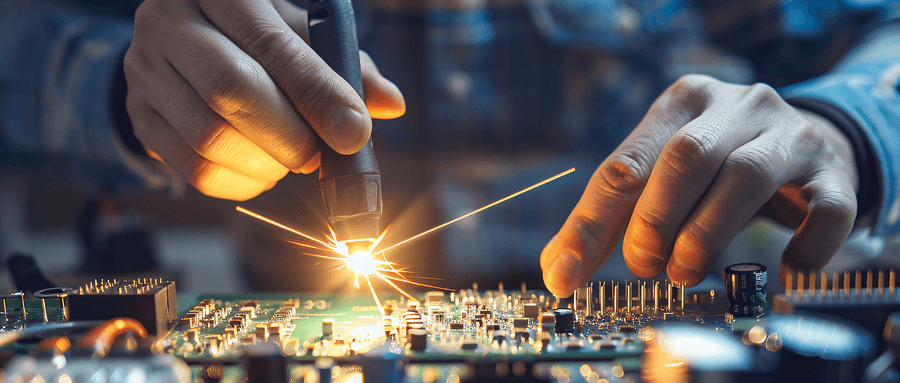

With the development of electronic products towards high density and multi-functionality, the welding quality of PCBA has become a core link to ensure product reliability.

Industry standards have put forward strict requirements for the appearance and porosity of solder joints. In fields such as automotive electronics and aerospace, relevant certifications are required to ensure compliance in process evaluation.

| Project Background

With the development of electronic products towards high density and multi-functionality, the welding quality of PCBA has become a core link to ensure product reliability.

Industry standards have put forward strict requirements for the appearance and porosity of solder joints. In fields such as automotive electronics and aerospace, relevant certifications are required to ensure compliance in process evaluation.

Moreover, welding defects may lead to high rework costs and legal risks. Therefore, evaluation tests have become a key means to optimize parameters, improve efficiency and control quality.

| Project Overview

The PCBA welding process evaluation test is a systematic test process to verify the correctness of the proposed welding process and ensure the stability and reliability of welding quality. Its core lies in providing scientific verification for formal production through the detection and data analysis of actual welded products.

| Test Objective

1. Verify the rationality of welding process parameters.

2. Ensure the stability and consistency of welding quality.

3. Comply with industry standards and regulations.

4. Optimize production efficiency and cost control.

5. Support new product development and process innovation.

| Testing Standards

IPC-A-610, IPC-TM-650, IPC-7095, etc.

| Service Products / Fields

Consumer electronics, automotive electronics, aerospace, etc.

| Test Items

Non-destructive testing (visual inspection, X-ray fluoroscopy inspection, ionic cleanliness)

Destructive analysis (cross-section analysis, dyeing test, solder joint strength, morphology observation, elemental analysis, etc.).

| Project Advantages

1. Visual inspection can accurately determine whether the solder joints meet the requirements of the standard IPC-A-610

2. X-ray fluoroscopy inspection can quantitatively evaluate whether the void ratio of each BGA solder joint meets the requirements of the standard IPC-7095

3. Ion cleanliness uses ion chromatography to evaluate the ion residues on the PCBA surface, including anions, cations, and weak organic acids, which can prevent failures caused by corrosion.

4. Cross-section analysis can reveal the internal microstructure of the solder joints and monitor the growth of the alloy layer.

5. The dyeing test comprehensively evaluates the soldering quality of the solder joints.

6. Solder joint strength quantitatively evaluates the push-pull force value of solder joints.