The nanoindenter is primarily used for testing the hardness and Young’s modulus of thin-film materials at the micro- and nanoscale. The test results are derived from the load–displacement curve, eliminating the need for microscopic observation of the indentation area.

| Project Overview

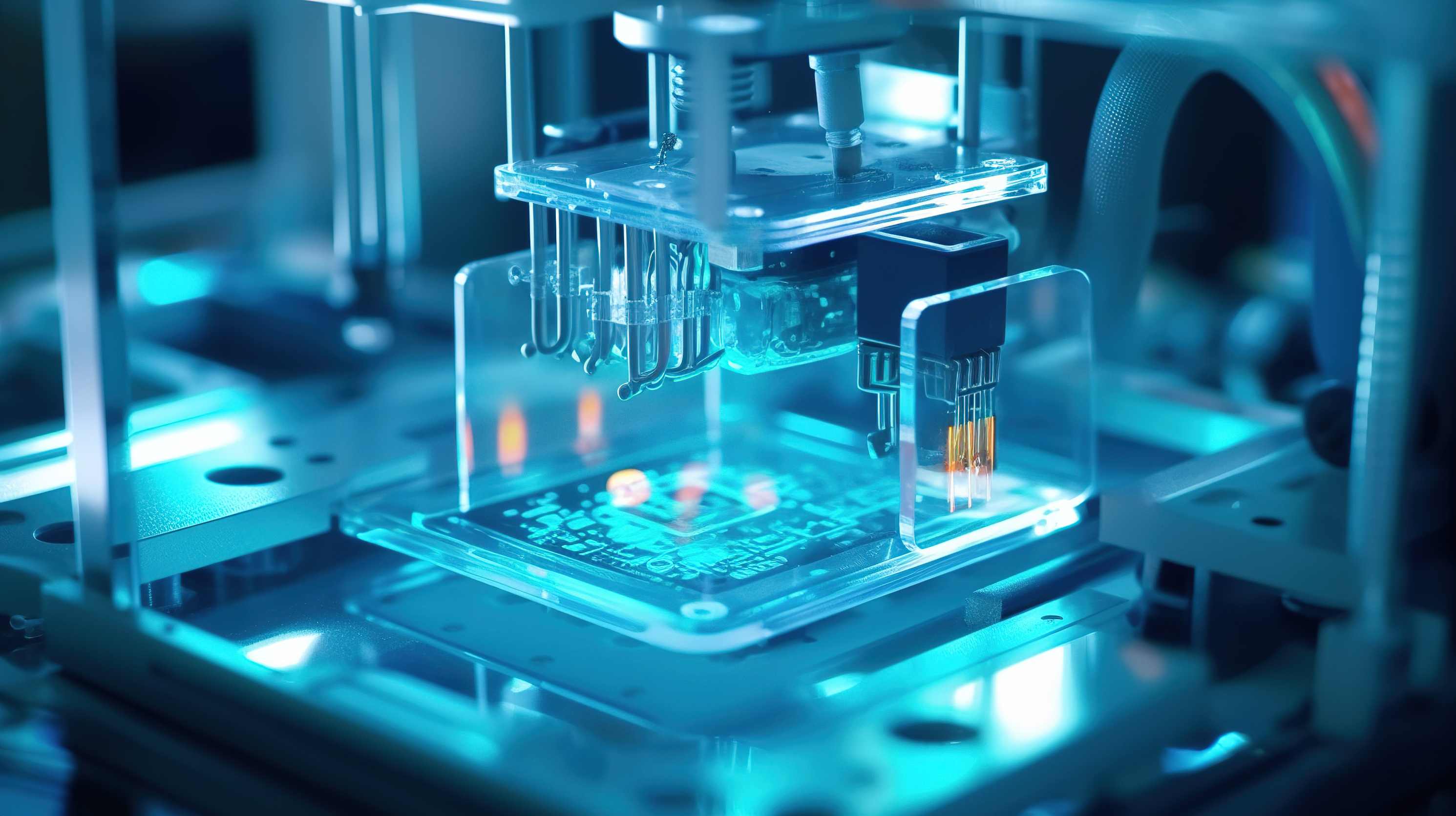

Principle: A minute diamond indenter is pressed into the material at the nanoscale to obtain critical mechanical parameters such as hardness and elastic modulus.

Advantage: It offers high spatial resolution and the capability of direct measurement, making it suitable for analytical testing of organic or inorganic, soft or hard materials.

| Project Objective

The nanoindenter is primarily used for testing the hardness and Young’s modulus of thin-film materials at the micro- and nanoscale. The test results are derived from the load–displacement curve, eliminating the need for microscopic observation of the indentation area. It is particularly suitable for measuring the mechanical properties of ultrathin materials such as films and coatings. At the nanoscale, it can characterize mechanical behaviors including load–displacement curves, elastic modulus, hardness, fracture toughness, strain-hardening effects, viscoelasticity, or creep behavior.

| Project Overview

Detection of red phosphorus content in products to ensure compliance with international environmental protection and health standards. As a key phosphorus-based flame retardant, red phosphorus is widely used across various industries. However, due to its environmental and health risks, global buyers and enterprises in regions such as Europe, the United States, Japan, and South Korea strictly regulate its use. Accurate quantification is performed through methods such as ICP-OES, PY-GC/MS, and GC-MS, thereby supporting product safety and regulatory compliance.

| Test Standard

GB/T 22458、GB/T 21838.1

| Service Products / Fields

It is widely applied in materials science, nanotechnology, the semiconductor industry, and the field of biomedicine, enabling precise measurement of material mechanical properties at the micro- and nanoscale.

| Project Advantages

With precise control and testing bandwidth, it provides outstanding flexibility, applicability, sensitivity, and measurement reliability. Equipped with quantitative nanoindentation and microindentation, nanoscratch testing, nanotribology and wear analysis, high-resolution in-situ Scanning Probe Microscopy (SPM) imaging, dynamic nanoindentation, and high-speed performance imaging, it enables a comprehensive understanding of nanoscale material behaviors.

1. Professional Team: Equipped with a number of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Services: Rapidly responding to customer needs and providing one-stop testing services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.