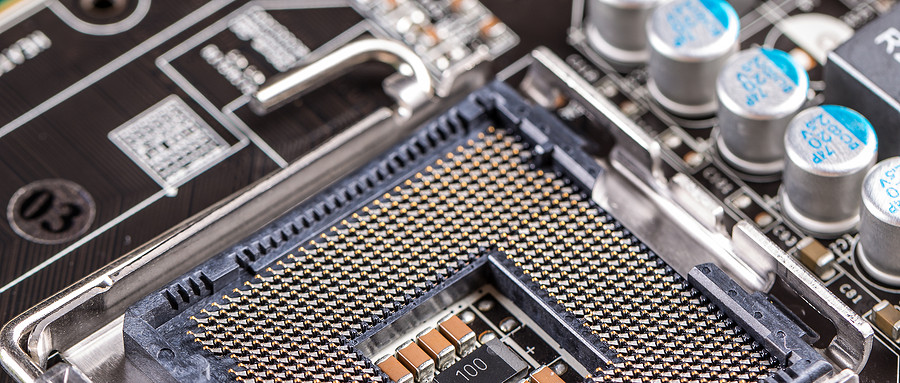

The thickness of the solder mask is one of the key parameters in PCB (Printed Circuit Board) manufacturing, which directly affects the insulation performance, solder resistance, and the protection effect of the circuit.

| Project Background

The thickness of the solder mask is one of the key parameters in PCB (Printed Circuit Board) manufacturing, which directly affects the insulation performance, solder resistance, and the protection effect of the circuit.

| Project Overview

The method of sectioning is used to measure the thickness of the solder mask. The general process is as follows: cut the PCB sample → embed it in resin → polish it → measure it under a microscope.

| Test Objective

Confirm that the thickness of the solder mask meets the product standards or the requirements of the procurement documents.

| Testing Standards

IPC-TM-650 2.2.1F Manual and Semi-automatic Sectioning Methods

IPC-TM-650 2.2.5A Cross-Section Dimensional Measurement

QJ 832B Test methods for multi-layer printed circuit boards for aerospace use

QJ 519A Test methods for printed circuit boards

QJ 831B General Specification for Multilayer Printed Circuit Boards for Aerospace Use

| Service Products / Fields

Related products: PCB FPC

Related fields: Consumer electronics, automotive electronics, aerospace electronic products

| MTT Advantages

1. Professional Team: Equipped with a number of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results. The high-precision measurement can reach ±1μm.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.