By applying the OBIRCH method, defects in circuits can be effectively localized, such as voids in metal lines, voids beneath vias, or high-resistance regions at via bottoms. It is also effective in detecting short circuits or leakage paths.

| Project Overview

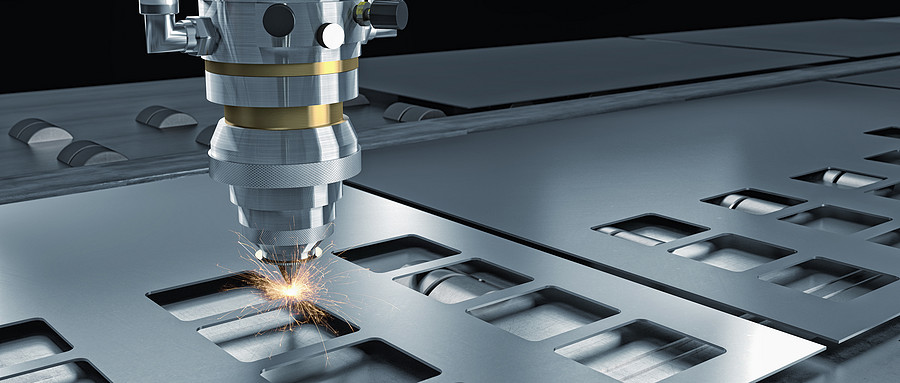

Optical Beam Induced Resistance Change (OBIRCH) is a technique in which a laser beam scans the surface of a device under constant voltage. Part of the laser energy is converted into heat. If defects exist in the metal interconnect lines, the temperature at the defect site cannot dissipate rapidly through the metal conductor. This results in a localized temperature rise, which further causes resistance and current changes in the metal line. By correlating the regions of variation with the laser scanning position, the defect location can be identified, thereby uncovering the failure mechanism and enabling root cause analysis.

| Test Objective

By applying the OBIRCH method, defects in circuits can be effectively localized, such as voids in metal lines, voids beneath vias, or high-resistance regions at via bottoms. It is also effective in detecting short circuits or leakage paths.

| Service Products / Fields

1. Semiconductor Materials: Detect defects in the metal interconnect lines of the material.

2. Integrated Circuits: Analyze failure causes in integrated circuits, such as voids in metal lines or voids beneath vias.

| Project Advantages

1. High sensitivity.

2. Wide wavelength detection range (near-infrared).

3. No destructive treatment of the sample is required.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.