The laboratory has established a comprehensive and rigorous quality management system, strictly adhering to international standards for management and operation. Testing solutions are flexibly adapted to meet diverse regulatory requirements across different markets, thereby satisfying customers’ varied testing needs.

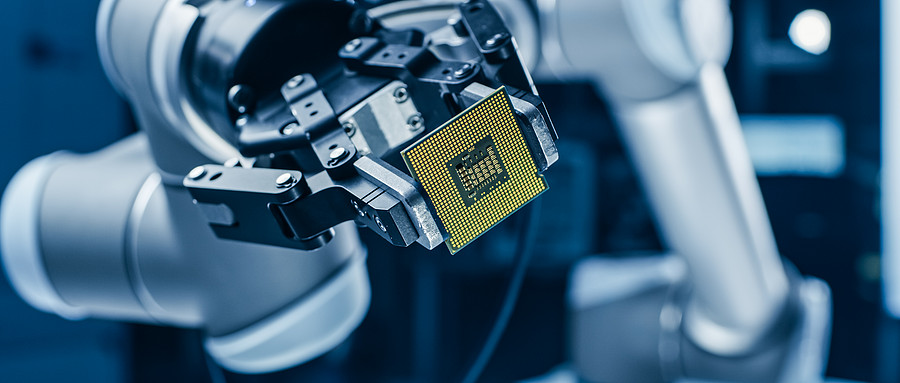

It constructs a closed-loop service system of "demand research - solution design - dynamic adjustment", and provides in-depth "industrial hospital"-style testing solutions according to the characteristics of semiconductor products, precisely matching the special needs of each stage of R&D/production.

Bringing together professionals from multiple disciplines—including materials engineering, electronic information, communication engineering, and optoelectronic information—the company has built a multidisciplinary technical team capable of delivering multidimensional solutions to meet complex testing requirements.

It is equipped with high-end equipment such as FIB (Focused Ion Beam), TEM, SEM/XPS, and Thermal EMMI, covering micro-structure analysis and device reliability equipment, to achieve all-round and precise diagnosis from materials to devices.