The test to determine the mechanical properties of materials when subjected to bending loads is one of the basic methods for material mechanical property tests. Common test items include flexural modulus, flexural strength, etc.

| Project Overview

The test to determine the mechanical properties of materials when subjected to bending loads is one of the basic methods for material mechanical property tests. Common test items include flexural modulus, flexural strength, etc.

| Testing Standards

GB/T 232, ISO 7438, GB/T 9341, ISO 178, ASTM D790, etc.

Test demonstration

Typical curve

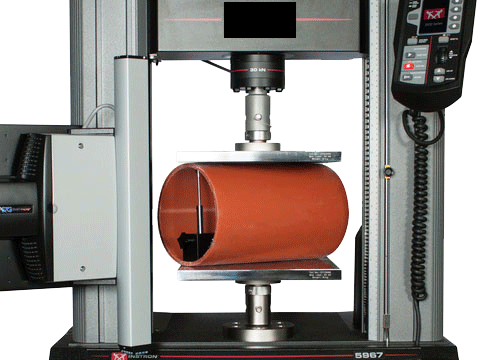

| Overview of Compression Test Items

The test to determine the mechanical properties of materials under axial static pressure is one of the basic methods for material mechanical property tests. The maximum compressive load at the time of specimen failure divided by the cross-sectional area of the specimen is called the ultimate compressive strength or compressive strength. The compression test is mainly applicable to brittle materials, such as cast iron, bearing alloys, and building materials. For plastic materials, the ultimate compressive strength cannot be measured, but the elastic modulus, proportional limit, and yield strength can be measured.

| Testing Standards

GB/T 7314, GB/T 1041

Compression test demonstration

Typical curve

| Test Objective

1. Improve product quality and reliability:

Bending and compression tests can comprehensively evaluate the mechanical properties of materials under different load conditions, which helps to identify potential weaknesses in materials and make improvements during the product design and manufacturing process, thereby enhancing the quality and reliability of products.

2. Promote materials science research:

The bending compression test is one of the important means in materials science research. Through the test, we can gain in-depth understanding of the mechanical behavior and deformation mechanism of materials, providing experimental basis and theoretical support for the development of materials science.

3. Promote the progress of engineering technology:

The results of the bending compression test can be directly applied in engineering practice, guiding the selection, design and application of materials, and promoting the development and progress of engineering technology. For example, in fields such as aerospace, automobile manufacturing and construction, the bending compression test plays an important role.

4. Ensure engineering safety:

Through the bending compression test, it can be ensured that the selected materials can withstand the expected load in practical applications, avoiding engineering accidents caused by material failure, thus ensuring the safety and stability of the project.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.