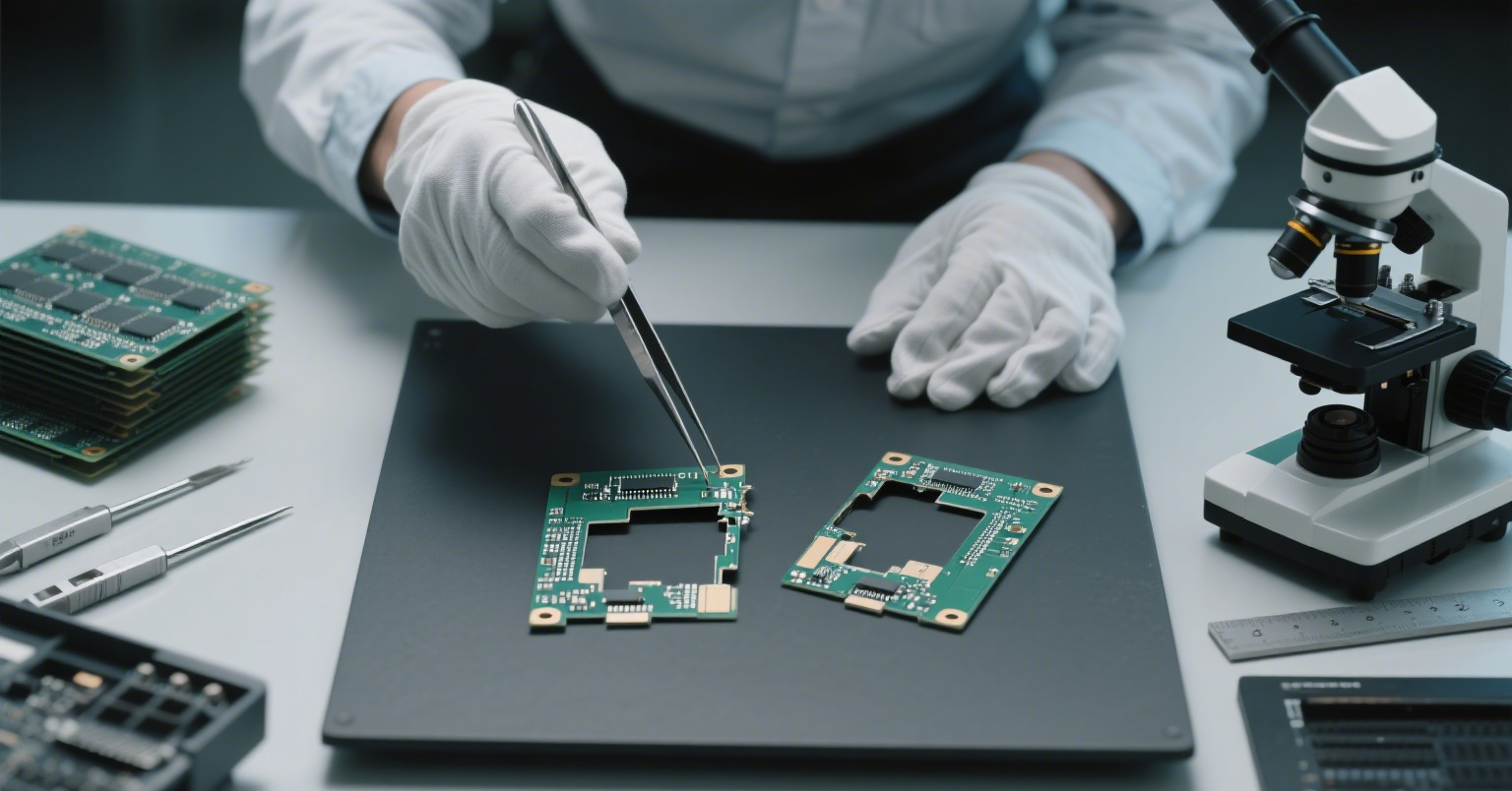

MTT possesses profound technical expertise in electronic component failure analysis, complete analytical methodologies, a vast database of failure analysis cases, and a team of seasoned experts, enabling us to provide high-quality and efficient failure analysis services.

The rapid advancement of electronic component technologies and improvements in their reliability have laid the foundation for modern electronic equipment. The fundamental task of component reliability work is to enhance the reliability of the components themselves. Therefore, it is essential to emphasize and accelerate the development of reliability analysis for components. By analyzing and identifying failure mechanisms, pinpointing failure causes, and feeding this knowledge back to design, manufacturing, and usage processes, corrective measures can be jointly studied and implemented to improve the reliability of electronic components.

Component manufacturers: deeply engaged in stages such as product design, production, reliability testing, and after-sales support, providing customers with theoretical foundations for improving product design and processes.

Assembly plants: responsible for assigning liability and providing a basis for claims; improving production processes; screening component suppliers; enhancing testing technologies; and optimizing circuit design.

Device agents: responsible for distinguishing quality liabilities and providing a basis for claims.

End-product users: provide evidence for improving operating environments and procedures, enhance product reliability, establish corporate brand image, and strengthen product competitiveness.

1. Provide the foundation for design and process improvements of electronic components, guiding the direction of reliability work.

2. Identify the root causes of electronic component failures and effectively propose and implement reliability improvement measures.

3. Improve product yield and operational reliability, thereby enhancing the enterprise’s core competitiveness.

4. Clearly define the party responsible for product failures, providing a basis for judicial arbitration.

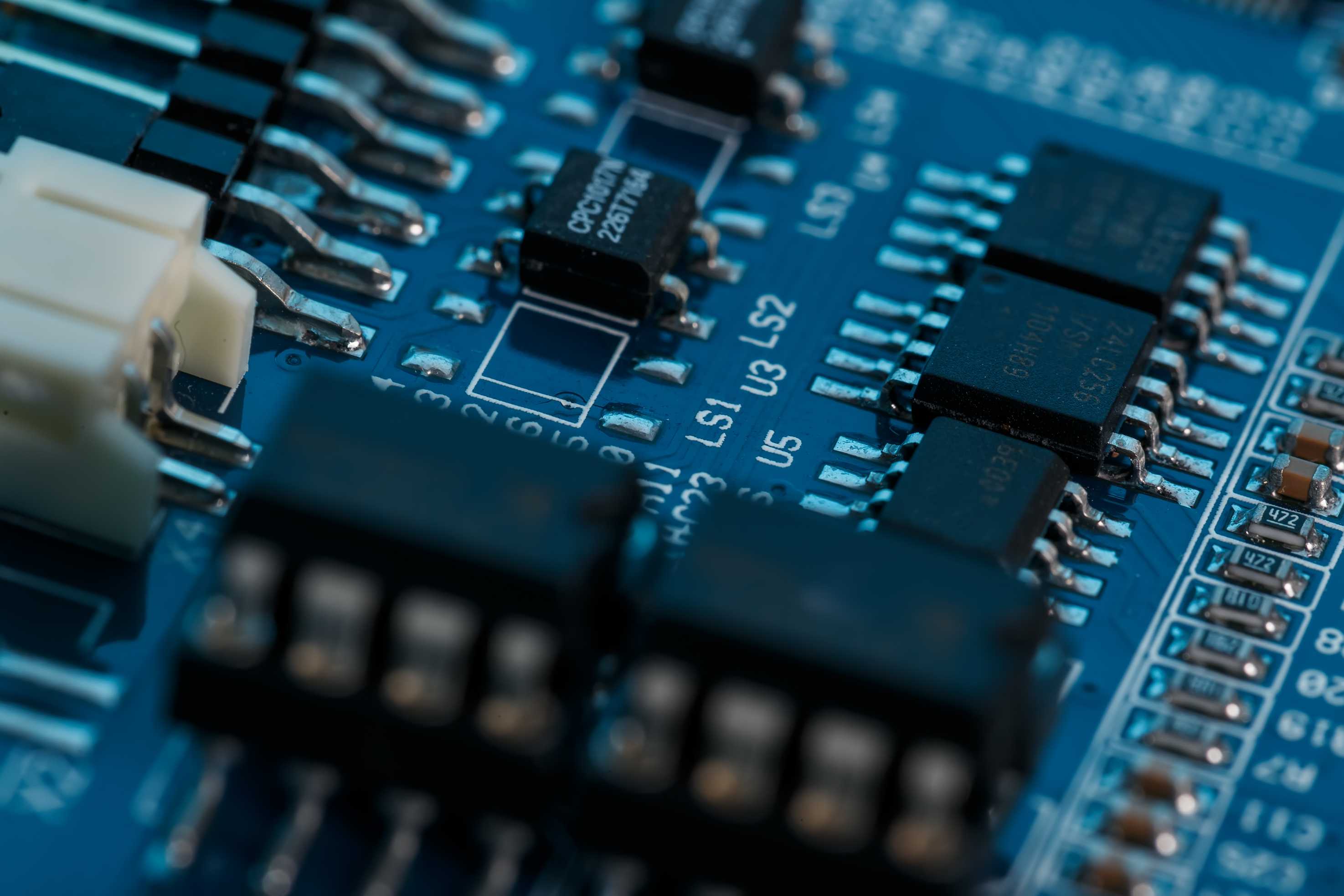

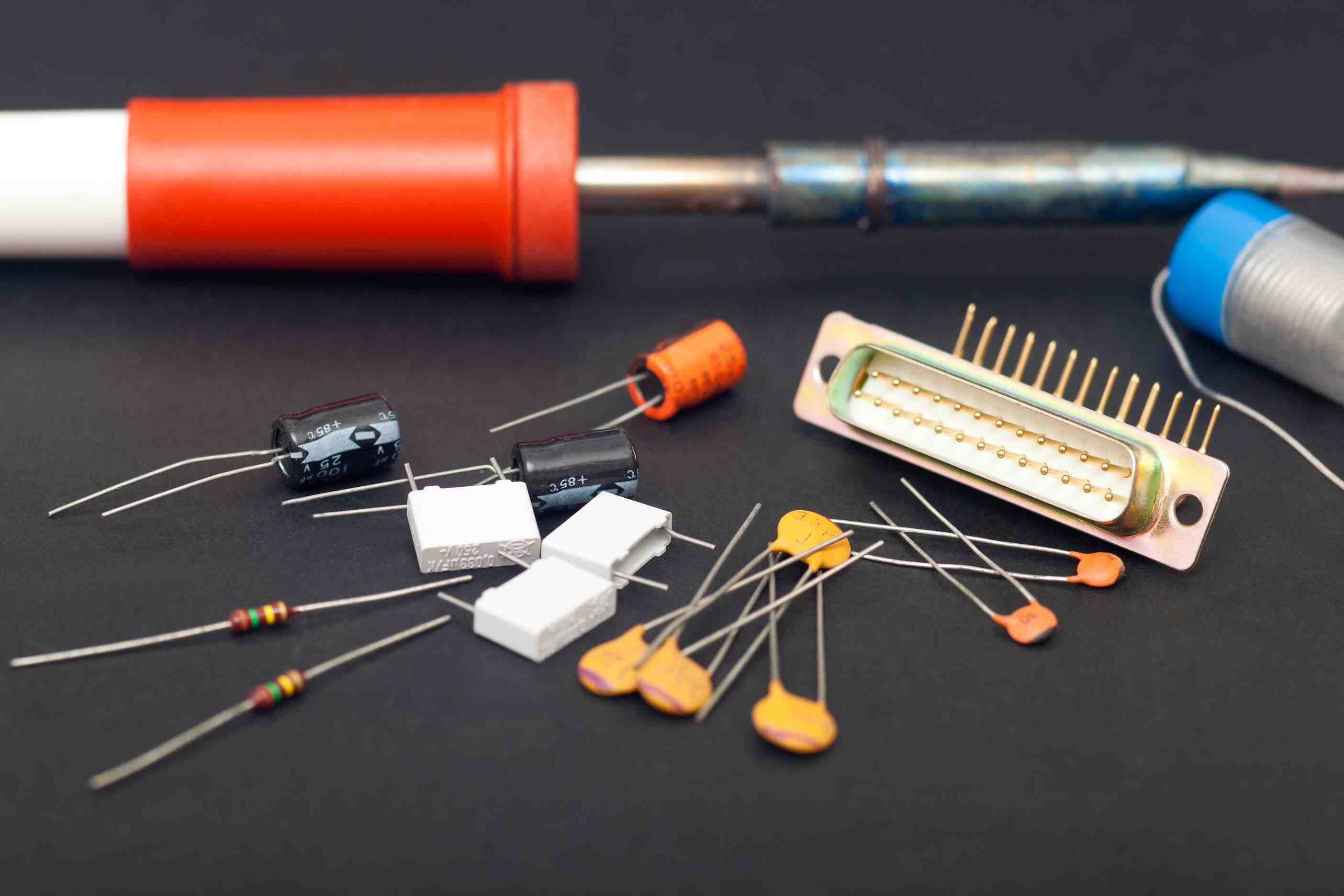

Types of analyzed components:

Integrated circuits, field-effect transistors, diodes, light-emitting diodes, transistors, thyristors, resistors, capacitors, inductors, relays, connectors, optocouplers, crystal oscillators, and various active/passive components.

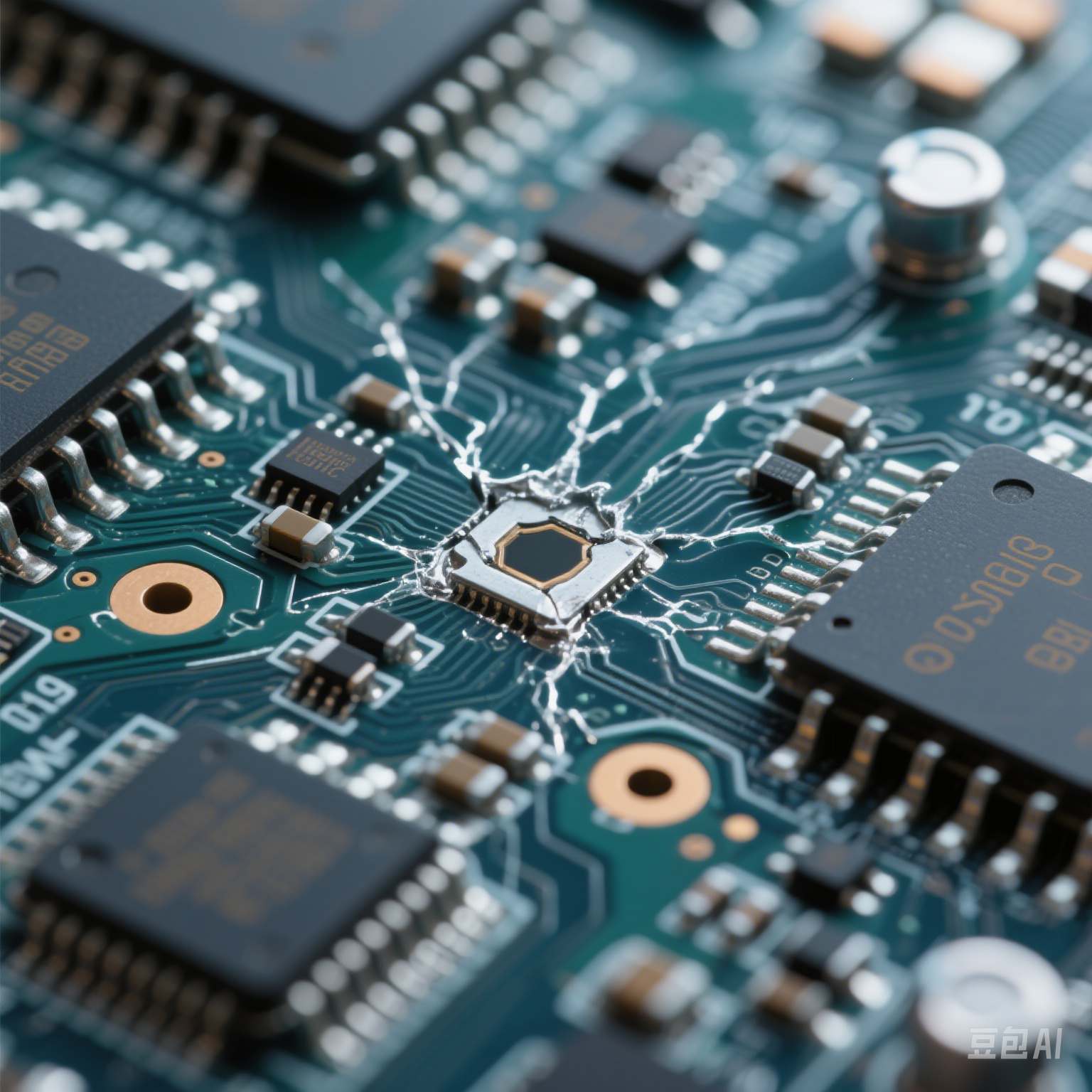

Open circuits, short circuits, burnout, leakage, functional failure, electrical parameter drift, and unstable failures.