The Plated Through-Hole (PTH) is a key structure in a PCB (Printed Circuit Board) for conductive connections between layers.

| Project Background

The Plated Through-Hole (PTH) is a key structure in a PCB (Printed Circuit Board) for conductive connections between layers.

| Project Overview

Commonly used detection methods for PTHs include:

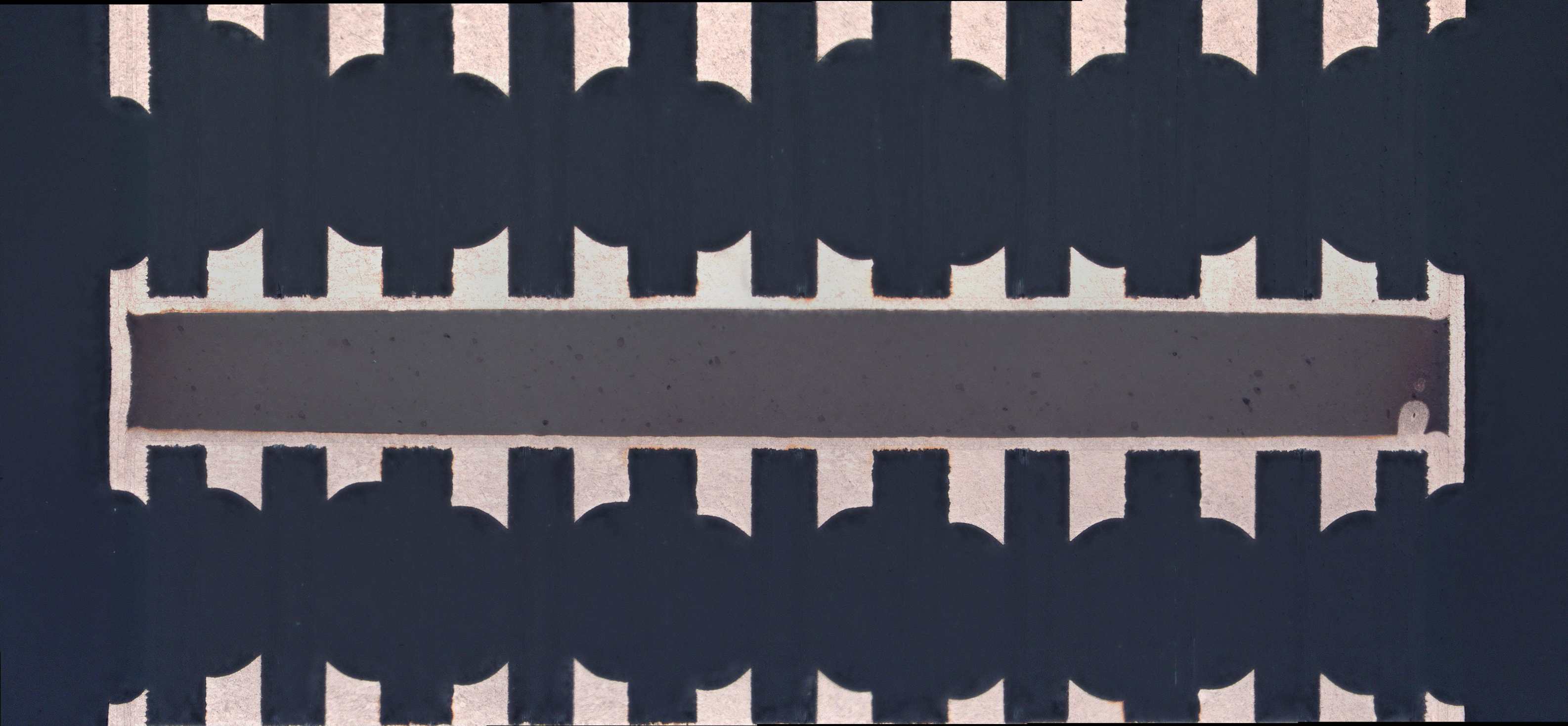

(1) Cross-Section analysis

Steps:

Sampling: Cut the PCB area containing the target hole.

Mounting: Encapsulate the sample with resin.

Grinding and polishing: Prepare a smooth cross-section.

Microscopic observation: Use a metallographic microscope or SEM (Scanning Electron Microscope) to inspect the quality of the hole wall plating.

Applicable standards:

IPC-TM-650 2.1.1 (Cross-Section preparation method)

IPC-A-600 (PCB acceptance standard)

(2) Backlight inspection

Check the continuity of the copper plating on the hole wall through the light-transmitting inspection, which is suitable for quickly screening defects.

| Test Objective

1. Evaluate the thickness, uniformity and integrity of the copper plating on the hole wall.

2. Measure whether the coating thickness meets the standards (such as IPC-6012, IPC-A-600).

3. Check for defects such as copper cracks, voids, separations, and (excessive) wicking in the holes.

| Testing Standards

IPC-6012: Performance specification for rigid PCBs

IPC-A-600: Acceptability standard for PCBs

IPC-TM-650 2.1.1: Manual and semi-automatic sectioning methods

QJ 832B Test methods for multi-layer printed circuit boards for aerospace use

QJ 519A Test methods for printed circuit boards

QJ 831B General Specification for Multilayer Printed Circuit Boards for Aerospace Use

| Service Products / Fields

Related products: PCB FPC

Fields involved: consumer electronics, automotive electronics, aerospace electronics.

| Project Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results. High accuracy and precision, strong applicability, and a solid foundation in methodology.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.