In many fields of modern industry, such as aerospace, energy and power, and automobile manufacturing, the performance of materials under long-term high-temperature and constant-stress conditions is crucial.

| Project Background

In many fields of modern industry, such as aerospace, energy and power, and automobile manufacturing, the performance of materials under long-term high-temperature and constant-stress conditions is crucial. Taking the aerospace field as an example, the components of aircraft engines need to withstand high temperatures and huge stresses for a long time. If the materials undergo excessive creep, it may lead to component deformation or even failure, seriously affecting flight safety. In the energy and power industry, high-temperature pipelines and boiler components also face such challenges. The creep performance of materials is directly related to the service life and operational reliability of equipment. Therefore, accurately measuring the long-term creep performance of materials plays an irreplaceable role in ensuring the safety and reliability of products and promoting the development of industry technology. Carrying out long-term creep test projects to provide a scientific basis for material performance evaluation has become an urgent need for current industrial development.

| Project Overview

The creep test is a mechanical property test of materials to measure the slow plastic deformation of materials under long-term constant temperature and constant stress. The higher the temperature or the greater the stress, the more significant the creep phenomenon. Creep can occur under a single stress (tensile, compressive, or torsional stress) or under combined stresses. Typically, creep tests are carried out under uniaxial tensile conditions.

The long-term strength test usually refers to the time when the material fractures under constant temperature and load; the long-term strength limit test refers to the maximum stress at which the material does not fracture at a certain temperature within a specified time.

| Test Objective

Firstly, comprehensively measure the creep performance of materials, including the creep rate of materials under different temperature and stress conditions and the characteristics of the steady-state creep stage, to deeply understand the deformation law of materials during long-term stress.

Second, accurately measure the creep rupture properties and stress relaxation properties of materials. The creep rupture properties reflect the ability of materials to resist fracture under constant temperature and stress, while the stress relaxation properties reflect the characteristic of stress decay over time when the total deformation of the material remains constant. The measurement of these performance indicators provides key data for material selection, design, and service life assessment, helping engineers optimize product design and improve the reliability and safety of products.

| Testing Standards

GB/T 2039

| Service Products / Fields

The creep rupture and creep performance tests have a wide range of applications, mainly targeting materials, components, and structural parts.

In terms of materials, it covers various metal materials, such as superalloys and stainless steels, which are widely used in high-temperature components of aerospace engines and gas turbines; polymer materials, such as special engineering plastics, are commonly used in high-temperature environment components in the fields of electronics, electrical appliances, and automobiles;

Composite materials, such as carbon fiber reinforced composites, have important applications in the fields of aerospace and sports equipment.

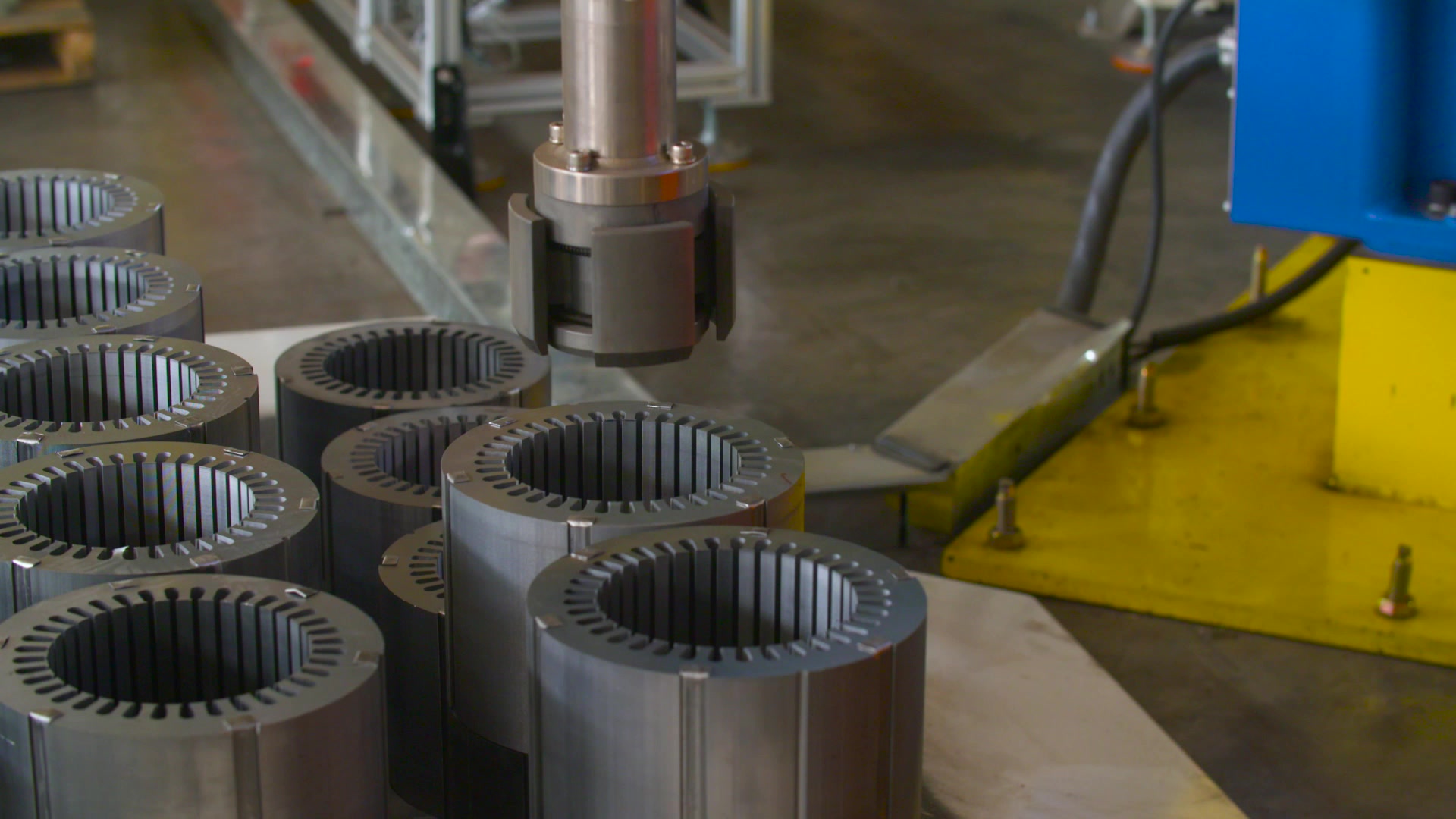

For components and structural parts, including aerospace engine blades, turbine disks, boiler pipes and steam turbine blades in the energy industry, etc. These components operate in high-temperature and high-pressure environments for a long time, and their creep rupture and creep performance are directly related to the safe and reliable operation of the entire equipment.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.