It has obtained multiple authoritative qualification certifications, such as CNA accreditation and CMA qualification. It has a mature quality management system, strictly monitors each testing project, and ensures that the traceability and accuracy of test results meet the standards.

It constructs a closed-loop service system of "demand research - solution design - dynamic adjustment", and provides in-depth "industrial hospital"-style testing solutions according to the characteristics of semiconductor products, precisely matching the special needs of each stage of R&D/production.

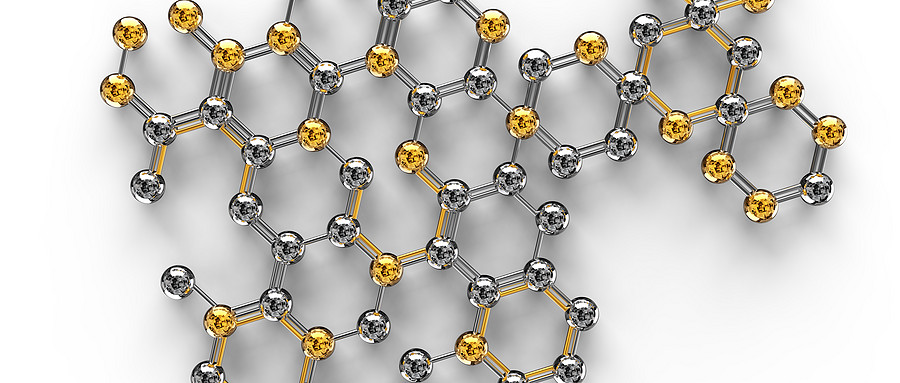

MTT has built a multidisciplinary technical team, with over 90% of members holding a bachelor’s degree or higher. Their professional backgrounds span material science, electronic information engineering, product reliability, and other disciplines, enabling multidimensional solutions for complex testing requirements.

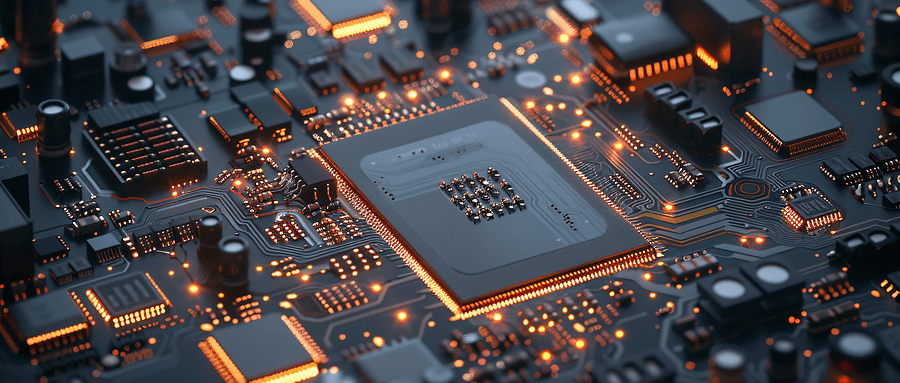

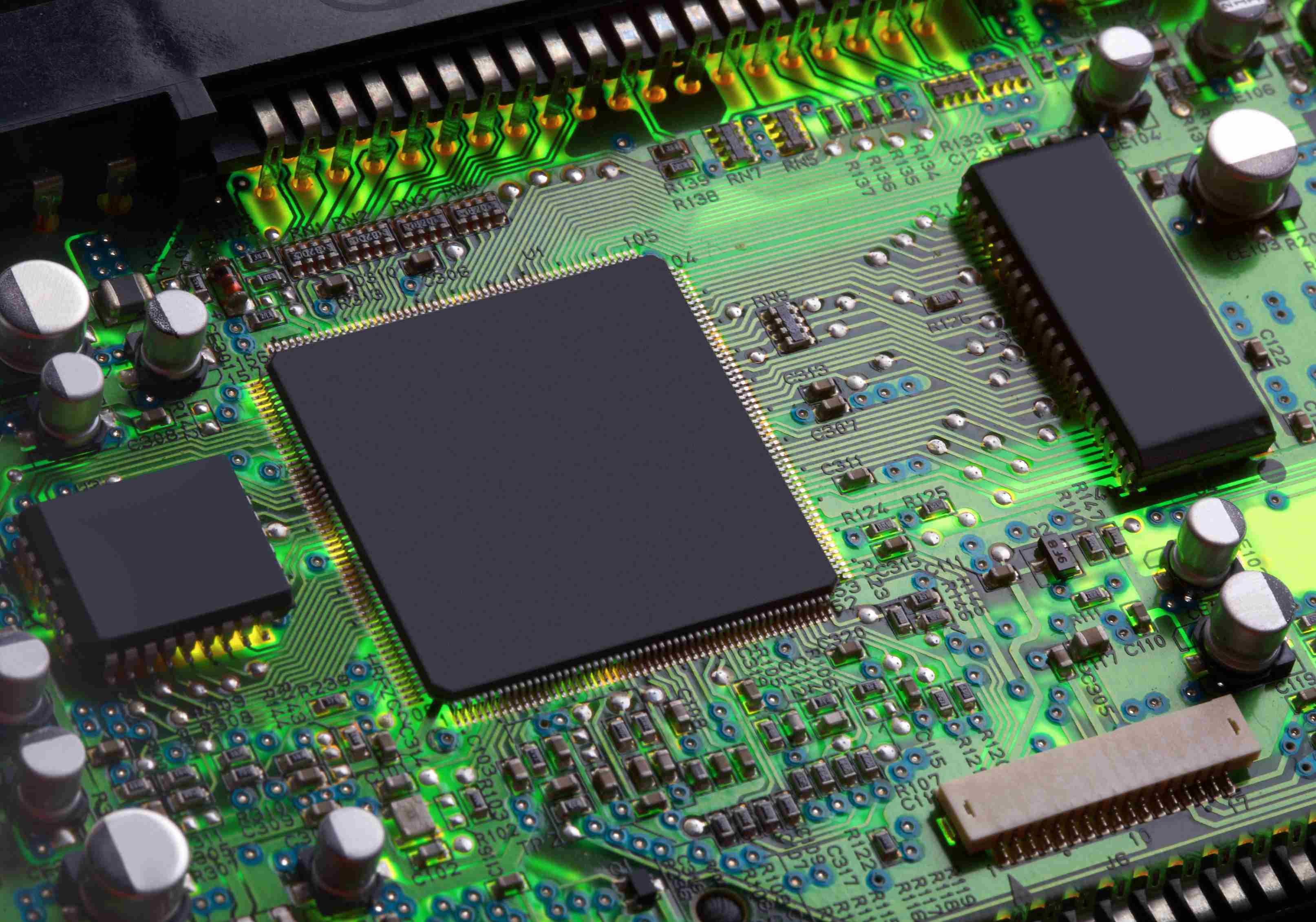

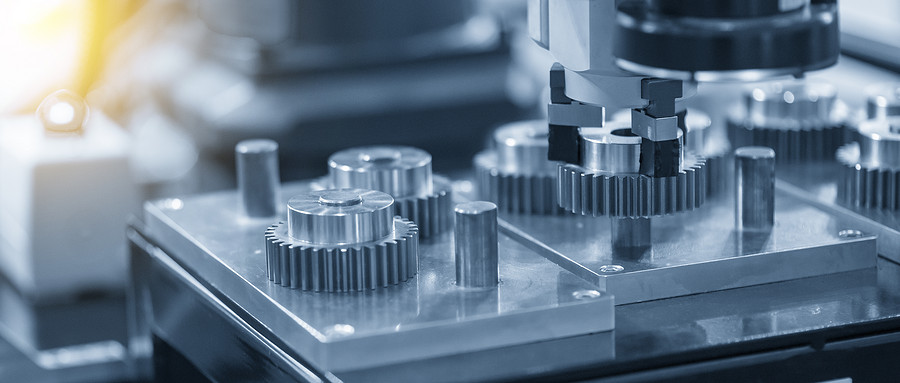

The testing equipment is of imported cutting-edge brands with advanced technology, which can meet the testing needs of electronic products in all fields from PCB bare boards to complete machines and provide scientific and accurate testing results.