Determine whether the PCB can withstand the thermal stress effects that may be exposed to extremely hot conditions during assembly, rework or repair.

| Project Background

Determine whether the PCB can withstand the thermal stress effects that may be exposed to extremely hot conditions during assembly, rework or repair.

| Project Overview

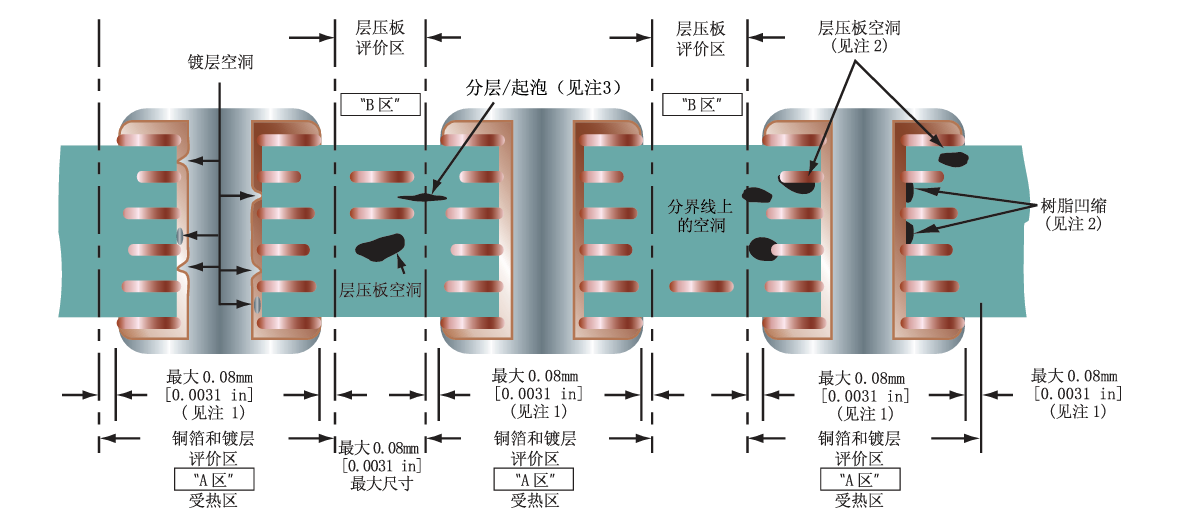

After baking the PCB or components (usually at 120~150 degrees Celsius for at least 6 hours) to remove moisture, process them multiple times in overheated solder (usually at 288 degrees Celsius for 10 seconds). Evaluate through visual inspection (for delamination, blistering, white spots, etc.) or Cross-Section (substrate delamination, cracks, blistering, warping, etc.).

| Test Objective

1. Determine whether the PCB material and process capabilities meet the thermal shock resistance requirements of the product

2. Simulate the usage environment and expose potential risks such as delamination in production in advance

| Testing Standards

IPC-TM 650 2.6.1 Thermal Stress, Laminates

GJB 362 General Specification for Rigid Printed Boards

QJ 832 Test Methods for Multilayer Printed Circuit Boards for Aerospace Use.

| Service Products / Fields

Related products: PCB/FPC

Related fields: Consumer electronics, automotive electronics, aerospace electronic products

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.