With the rapid development of the electronics industry, electronic products become increasingly miniaturized, thin, and light. This trend places higher requirements on the reliability and durability of electronic products. To ensure that electronic products can operate stably for a long time in various environments, reliability testing of products and their components has become particularly important.

With the rapid development of the electronics industry, electronic products become increasingly miniaturized, thin, and light. This trend places higher requirements on the reliability and durability of electronic products. To ensure that electronic products can operate stably for a long time in various environments, reliability testing of products and their components has become particularly important.

Traditional insulation performance tests are mostly one-time detections at normal temperature and under normal conditions, which cannot simulate the continuous impact of environmental factors on insulation performance during long-term use. Therefore, a test method that can simulate complex environments and evaluate the change of insulation performance over time is needed. The SIR (Surface Insulation Resistance) test emerged as the times require.

| Project Background

With the rapid development of the electronics industry, electronic products become increasingly miniaturized, thin, and light. This trend places higher requirements on the reliability and durability of electronic products. To ensure that electronic products can operate stably for a long time in various environments, reliability testing of products and their components has become particularly important.

Traditional insulation performance tests are mostly one-time detections at normal temperature and under normal conditions, which cannot simulate the continuous impact of environmental factors on insulation performance during long-term use. Therefore, a test method that can simulate complex environments and evaluate the change of insulation performance over time is needed. The SIR (Surface Insulation Resistance) test emerged as the times require.

| Project Overview

The SIR (Surface Insulation Resistance) test is a key detection method used in the electronics manufacturing industry to evaluate the surface insulation performance of printed circuit boards (PCBs), electronic components, or assemblies. Its core purpose is to detect the impact of surface contaminants (flux residues, metal ions, dust, etc.) or a humid environment on insulation performance, and to avoid problems such as short-circuits and leakage currents caused by insulation failure.

| Test Objective

1. Evaluate surface insulation performance: By measuring the resistance value between two points on the surface of the insulating material, determine whether it can effectively prevent current leakage and avoid short-circuits, leakage currents, or electrical performance degradation caused by surface contamination.

2. Verify process reliability: Detect whether there are residual contaminants (flux residues, finger oil stains, dust, etc.) in the process of welding, cleaning, assembly, etc., to ensure that the process control meets the standards.

3. Forecast product life: In an accelerated environment such as high humidity and heat, simulate the surface insulation degradation trend of the product during long-term use, and discover potential failure risks (such as short-circuits caused by electrochemical migration) in advance.

| Testing Standards

IPC-TM-650 2.6.3.3B, IPC-TM-650 2.6.3.7, GB/T 4677, etc.

| Service Products / Fields

Manufacturing and maintenance of electrical equipment:

Factory inspection and regular maintenance of the insulation performance of equipment such as motors, transformers, cables, and switches.

For example: Insulation testing between transformer windings and between windings and the enclosure to ensure that there is no leakage or short-circuit during equipment operation.

Electronic components and circuit boards:

Inspection of the insulation layers of components such as capacitors, resistors, and integrated circuits, as well as insulation testing between the circuits of PCB boards (printed circuit boards).

Research and development and quality control of insulating materials:

Performance evaluation of insulating materials such as plastics, rubbers, ceramics, and glass fibers, such as judging the insulation stability of materials in environments such as humidity and high temperature.

High-end fields such as aerospace and automotive electronics:

In scenarios with extremely high requirements for insulation reliability (such as aircraft cables and insulation layers of automotive power batteries), the insulation resistance needs to be strictly tested to ensure safety.

| Project Advantages

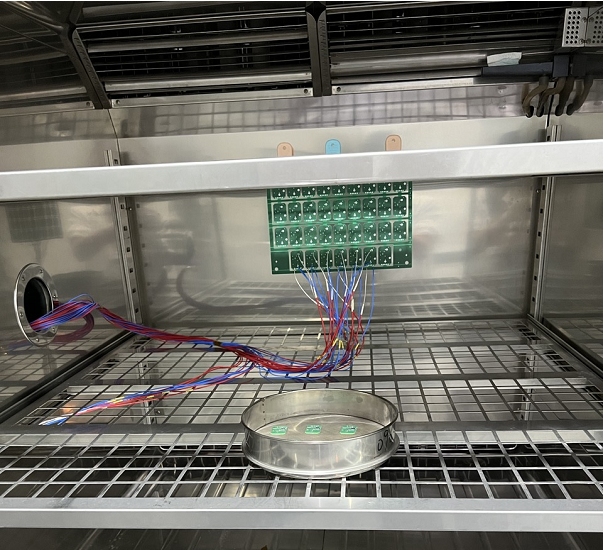

MTT has three sets of insulation resistance testing systems (IPC-650S-1K5, IPC-650S, TI-SIR-256-5-4), with a total of 256 + 256 + 256 = 768CH. It can automatically collect insulation resistance test data. Among them, the maximum test voltage of the IPC-650S-1K5 can reach 1KV, and the measurement range can reach 10⁶-10¹⁴ Ω.

| Testing Principle

Under the specified environmental conditions (temperature, humidity), apply a DC voltage to two electrodes (or conductors) on the surface of the test specimen, measure the leakage current between the electrodes, and calculate the surface insulation resistance (SIR = applied voltage / leakage current) according to Ohm's law.

| MTT Advantages

1. Professional Team: The project team has rich testing experience and professional knowledge, and can provide customers with comprehensive testing solutions and technical support.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.