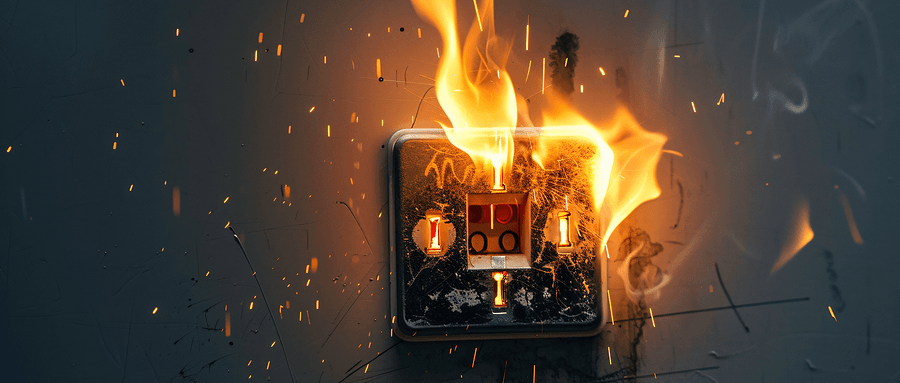

The flame retardancy of PCB combustion is a core indicator for ensuring the safety of electronic devices, which is directly related to fire prevention and personal safety. Global mandatory certification systems (such as UL/IEC/GB) require PCBs to pass standardized combustion tests to verify the flame spread resistance of the substrate under high temperature or open flames.

| Project Background

The flame retardancy of PCB combustion is a core indicator for ensuring the safety of electronic devices, which is directly related to fire prevention and personal safety. Global mandatory certification systems (such as UL/IEC/GB) require PCBs to pass standardized combustion tests to verify the flame spread resistance of the substrate under high temperature or open flames. With the popularization of halogen-free environmental protection materials and the application of high-density PCBs, accurately monitoring the effectiveness of flame retardants and preventing the risk of carbonization during reflow soldering have become an unavoidable technological need in the industrial chain.

| Project Overview

This project classifies the flame retardancy levels of PCB samples according to core standards such as UL 94 and GB/T 2408 (horizontal/vertical combustion) through key steps such as controllable ignition, measurement of afterflame/afterglow time, and observation of droplet behavior.

| Test Objective

1. Provide the flame retardancy level of materials;

2. Conduct in-depth diagnosis of the causes of flame retardancy failure;

3. Establish an enterprise flame retardancy database.

| Testing Standards

UL 94 Combustion test for plastic materials used for parts in devices and appliances

GB/T 2408 Determination of burning characteristics - Horizontal and vertical test

| Service Products / Fields

Consumer electronics, automotive electronics, electronic manufacturing, PCB design and materials science, aerospace, communications, new-energy electronics, etc.

| MTT Advantages

1. Professional Team: A team of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results. High accuracy and precision, strong applicability, and a solid foundation in methodology.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.