Multi functional micro solder joint strength test is used to measure wire bonding strength, component bonding strength, solder joint pull-out and shear strength, evaluate strength distribution or determine whether the strength meets relevant requirements.

| Project Overview

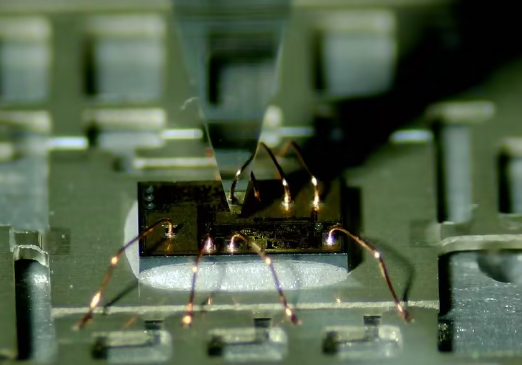

Testable items include: chip shear testing; bond pull testing; solder ball shear testing; solder ball pull-off testing; and thrust testing of SMT soldered components.

| Test Objective

Measurement of bond wire strength, component adhesion strength, and solder joint pull-off and shear strength, with evaluation of strength distribution or verification of compliance with relevant requirements.

| Testing Standards

GJB 4027B-2021;GJB 548C-2021;GJB 128B-2021;STD883, ASTM F1269, JEDEC JESD 22-B116, JEDEC JESD 22-B117, JEITA EIAJ ET-7407。

| Service Products / Fields

Widely applied in chip packaging process testing, PCBA electronic assembly testing, automotive electronics, aerospace, defense industry, and product failure reliability testing during service.

| Project Advantages

1. Broad applicability, with different testing modules configurable to meet diverse testing requirements.

2. Rapid testing actions, stable machine operation, and high testing accuracy.

3. Equipped with a computer for real-time display of tensile curves.

4. The left and right joystick controllers can swing freely, enabling simple and convenient operation.

| Test Principle Diagram

Solder ball shear

Solder ball pull-off

Bond pull

Ball shear

| Test Analysis Diagram

| MTT Advantages

1. Professional Team: Equipped with a number of highly experienced testing engineers and technical experts.

2. Advanced Equipment: Equipped with internationally leading testing instruments to ensure accuracy and reliability of results.

3. Efficient Service: Rapidly respond to customer needs and provide one-stop, high-efficiency inspection services.

4. Authoritative Certification: The laboratory is certified by ISO/IEC 17025, ensuring that test reports have international credibility.