It has obtained multiple authoritative qualification certifications, such as CNAS, CMA, Nadcap qualifications, and the qualification recognized by CFM engine manufacturers, etc., providing high-quality services for customers in an all-round way.

Providing aviation customers with 7*24h services for chip and oil filter projects, with chip analysis reports delivered in as fast as 3 hours and oil filter analysis reports within 24 hours, safeguarding civil aviation flights across the Asia-Pacific region.

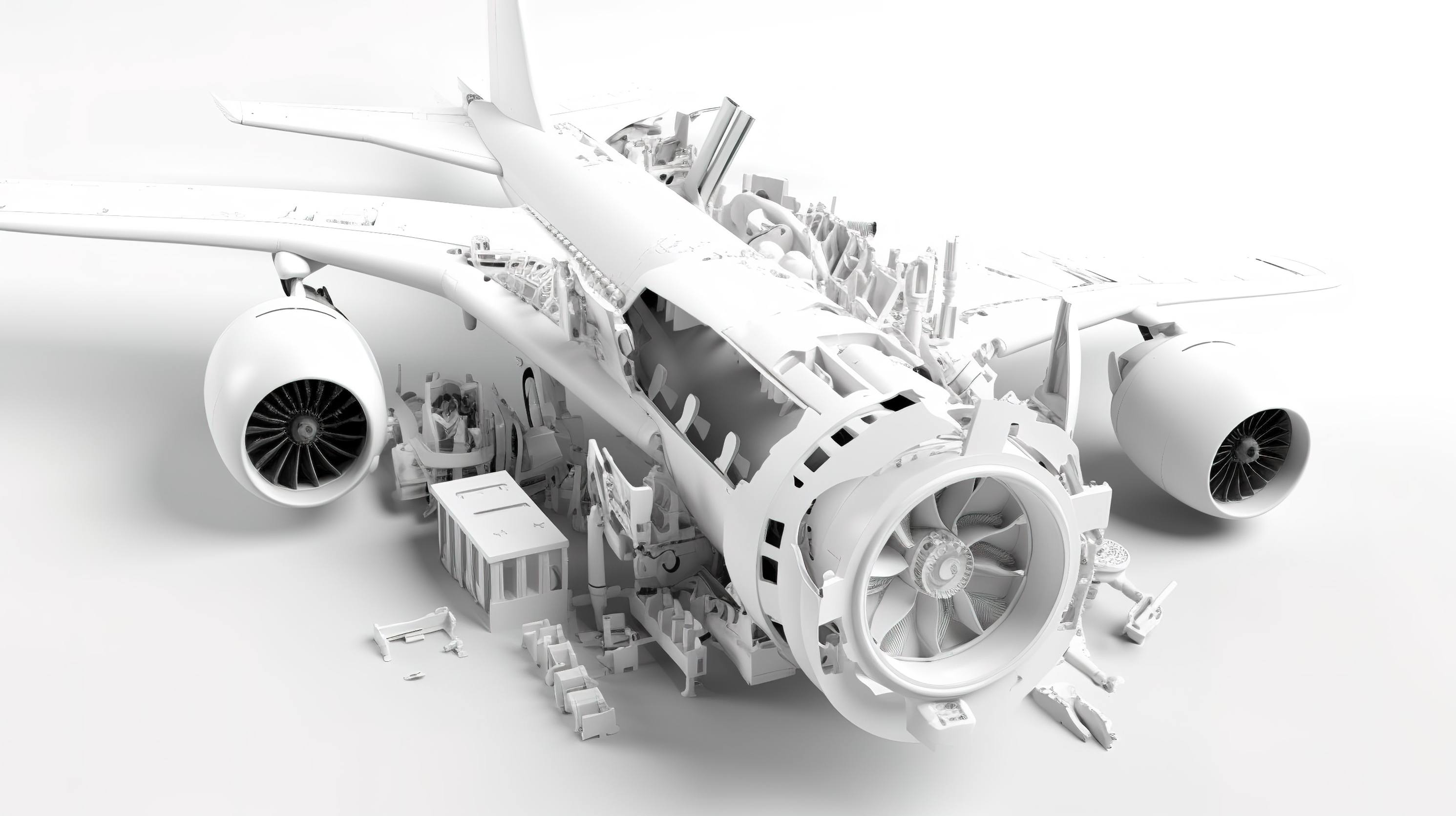

Covering expertise in materials engineering, chemical engineering, mechanical engineering, and airport operations, we have built a multidisciplinary technical team to provide aviation customers with comprehensive and multidimensional solutions.

Equipped with SEM+EDS, mechanical performance testing equipment, oil analysis equipment, and XRF, enabling comprehensive testing from materials to components.