The counterfeit refurbishment testing of components is the "firewall" of quality control, which is important for avoiding failure risks, maintaining market fairness, and safeguarding user rights through technological means, promoting industrial upgrading, and providing key support for the sustainable development of high-end manufacturing.

| Risks and Hazards Posed by Counterfeit and Refurbished Devices

· High risk of failure, with significant randomness in failure occurrence.

| Refurbished Materials Are Largely Sourced from Used Recycled Devices

· Degradation during usage, with multiple stresses acting together, typically in the late stage of the bathtub curve;

· Damage introduced during the refurbishment process.

| Counterfeit Materials Are Often Inferior Substitutes or Domestic Parts Posed as Imported Ones to Gain Profit Margins.

Characteristics of Such Materials:

· Identical appearance;

· Functionally consistent.

|

序号 No. |

试验项目 Test items |

检查内容 Inspection Items |

|

1 |

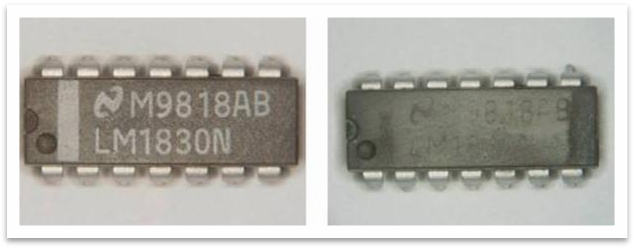

外观检查 Appearance inspection |

商标、型号、批号、划痕、裂纹、引脚氧化腐蚀变色等等 Trademarks, models, batch codes, scratches, cracks, pin oxidation, corrosion discoloration, and others. |

|

序号 No. |

试验项目 Test items |

检查内容 Inspection Items |

|

2 |

X射线检查 X-ray inspection |

内部结构(焊线方式、引线框架、芯片等) Internal structure (bonding method, lead frame, chip, etc.) |

|

序号 No. |

试验项目 Test items |

检查内容 Inspection Items |

|

3 |

丙酮测试 Acetone test |

表面标志能否被擦拭 Whether surface markings can be wiped off |

|

4 |

开封检查 Decapsulation inspection |

生产商标志、版本数据代码、焊线质量等 Manufacturer logos, version data codes, wire bonding quality, and so on. |

|

5 |

晶元工艺分析 Wafer Process Analysis |

分析晶元内部工艺、掺杂工艺等 Analysis of internal wafer processes, doping processes, and related factors |