01 Conference Overview

Conference Introduction

Failure analysis has garnered increasing attention across various sectors in recent years. Not only does it guide mechanical product design, material selection, processing inspection, and quality management, but failure analysis technology also serves as a crucial basis for establishing technical specifications, scientific development plans, and legal arbitration. With China's rapid economic development and growth in the equipment manufacturing industry, failure analysis technology is finding increasingly widespread application.

The 2025 National Failure Analysis Academic Conference will convene in Beijing in August 2025. Jointly organized by the Failure Analysis Branch and the Physical and Chemical Testing Branch of the Chinese Mechanical Engineering Society, this conference represents another gathering for China's failure analysis industry, offering high-level, information-rich academic exchange. Distinguished academicians, scholars, and experts in failure analysis will deliver keynote presentations, summarizing research achievements in failure analysis and prevention, sharing experiences and techniques, and discussing strategic development for the discipline.

We cordially invite experts, scientists, university faculty and students, as well as professionals from the industry engaged in failure analysis and physical and chemical testing to participate. During the conference, a Failure Analysis and Physical/Chemical Testing Sample Exhibition will be organized, alongside expert consultation activities, providing a broader platform for exchange among enterprises, manufacturers, and engineering technicians.

Conference Dates

August 9–12, 2025. Registration: August 9, 2025. Conference: August 10–12, 2025.

Venue

Shahé Campus, Beihang University.

Organizers

Failure Analysis Branch, China Society for Mechanical Engineering

Physical and Chemical Testing Branch, China Society for Mechanical Engineering

Host Institution

Beihang University

02 Call for Papers

This conference invites submissions nationwide. Conference proceedings will be indexed on CNKI, with selected papers published in book form (with official ISBN). Due to limited publication capacity, submissions will be prioritized by submission date and quality until capacity is reached. We encourage active participation! Scope and requirements are as follows:

1) Principles and methods of failure analysis;

2) Physical and chemical testing techniques in failure analysis;

3) Analysis of typical failure cases;

4) Failure analysis and safety, risk assessment and management;

5) Analysis related to failure and design, materials and processes, and service environments;

6) Failure analysis prevention and prediction technologies;

7) Failure analysis and prevention for special materials and equipment;

8) Other relevant failure analysis and prevention technologies.

Research findings, academic and technical papers, analytical experiences, and recommendations related to failure analysis and physicochemical testing that have not been formally published elsewhere are welcome for submission.

Conference papers may be submitted via email. The subject line must clearly state “Submission for the 2025 National Failure Analysis Academic Conference,” and the Conference Secretariat must be notified simultaneously. After expert review, accepted submissions will receive notification of acceptance and page charges. For publication in book format, the page charge is 600 RMB per paper, limited to 4 pages per paper. Each additional page incurs an extra charge of 150 RMB. For publication in a conference proceedings collection indexed by CNKI, the page charge is 400 RMB per paper, limited to 4 pages per paper. Each additional page incurs an extra charge of 150 RMB. Papers for which page charges remain unpaid will not be included in the conference proceedings. Submitted papers must adhere to the formatting requirements specified in Attachment 1: “Paper Submission Template.”

Full paper submission deadline: June 15, 2025.

03 Payment Methods

Conference Registration Fees

1) Register by June 30: ¥1,600;

2) Register after June 30: ¥1,800;

3) Failure analysts, failure analysis experts, and students from the Failure Analysis Branch of the Chinese Mechanical Engineering Society: ¥1,600.

The Chinese Mechanical Engineering Society will collect registration and publication fees for this conference and issue invoices for conference fees and publication charges.

Official Conference Website:

https://meeting.cmes.orgmid=371&sid=1485;

Conference Registration Payment QR Code

Please stay tuned for updates on the website and log in to register and make payments.

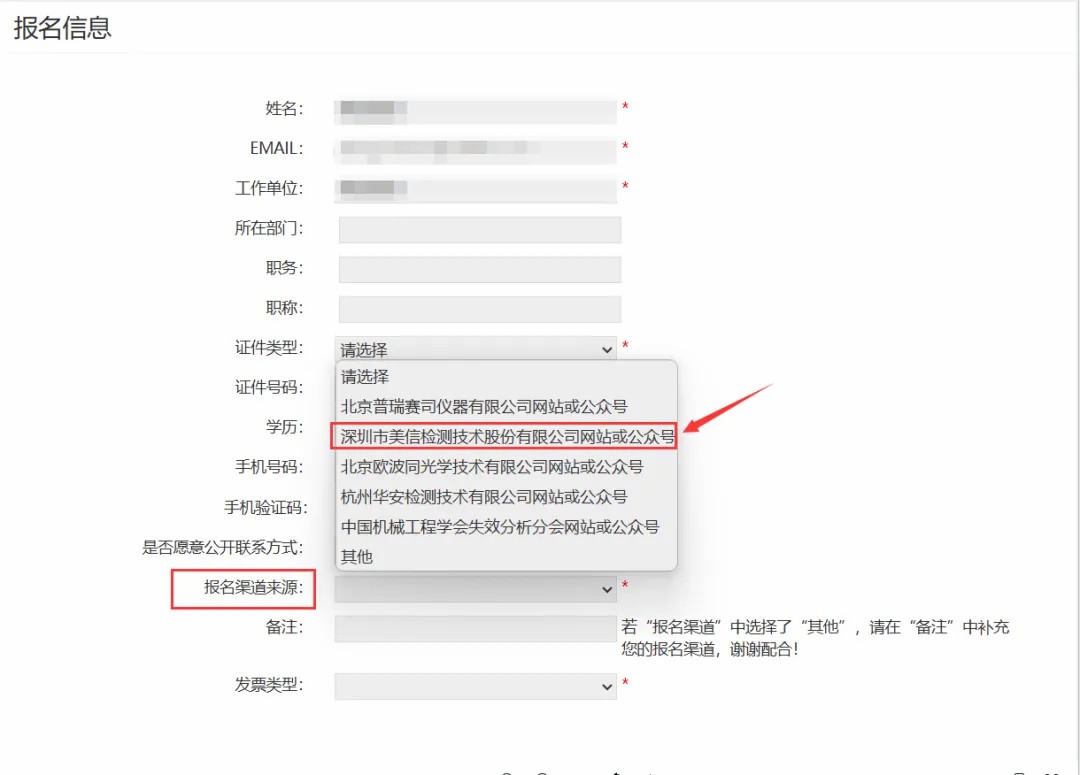

Registration Channels:

"Shenzhen Meixin Testing Technology Co., Ltd.

Website or Official Account"

Sponsorship and Commercial Partnerships

To meet the promotional and networking needs of industry enterprises, the conference offers diverse advertising channels including conference proceedings advertisements, technical lectures, and corporate image displays. Companies interested in collaboration are welcome to contact Meixin Testing.

Contact Information

Paper Submission:

E-mail: shixiaofenxi@cmes.org

Contact:

Zhang Meixin 18126500389 (also WeChat ID)