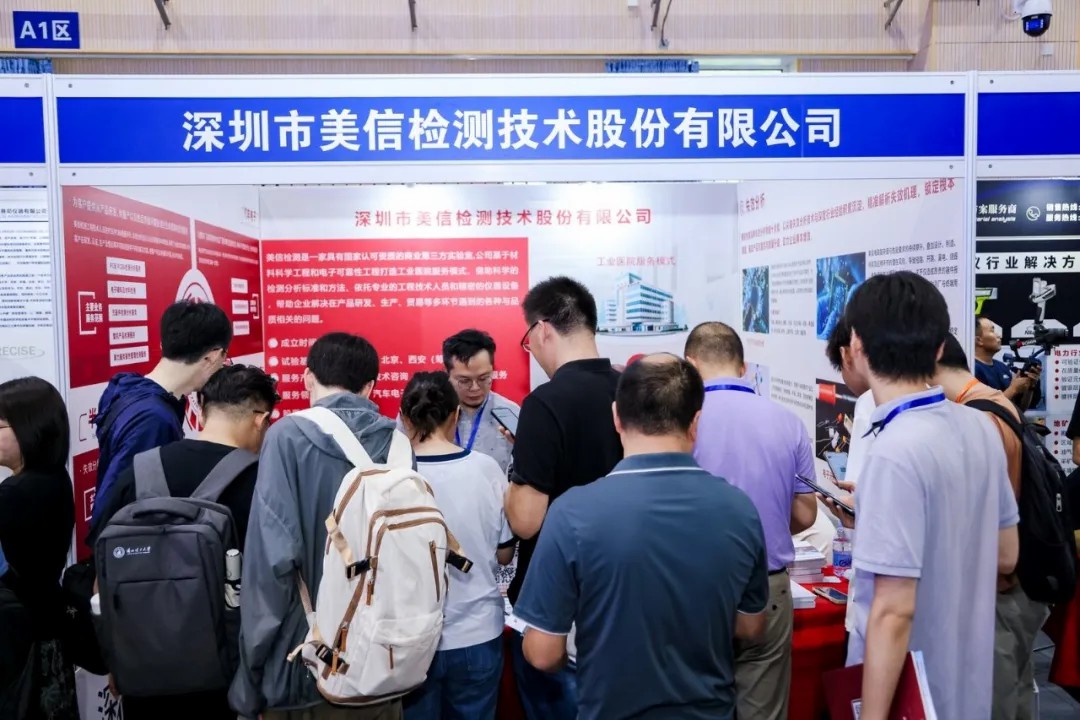

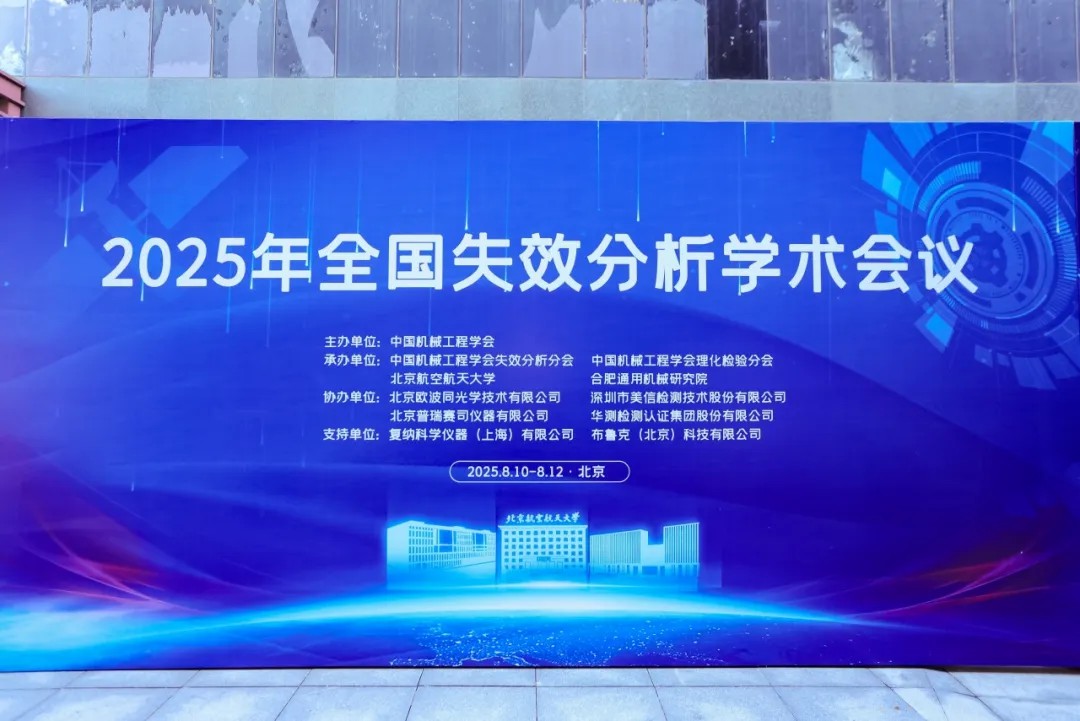

From August 10 to 12, 2025, the “2025 National Failure Analysis Academic Conference” and the “China College Students Mechanical Engineering Innovation and Creativity Competition—‘Oubotong Cup’ Failure Analysis Contest,” jointly organized by the Failure Analysis Branch of the Chinese Mechanical Engineering Society and Beihang University, were successfully held at Beihang University's Shahu Campus. This conference brought together leading experts, scholars, and industry elites in China's failure analysis field to collectively explore the latest advancements and practical applications of failure analysis technology. As a co-organizer, Shenzhen Meixin Testing Technology Co., Ltd. (hereinafter referred to as “Meixin Testing”) made a remarkable appearance at this grand event, comprehensively showcasing the company's profound technical expertise and professional capabilities in the field of failure analysis. During the conference, Meixin Testing comprehensively showcased its expertise and advanced equipment in failure analysis through on-site demonstrations and interactive experiences. With over a decade of deep expertise in failure analysis, Meixin Testing leverages cutting-edge failure analysis technologies and extensive industry experience to precisely identify failure mechanisms, pinpoint root causes, drive product reliability and quality upgrades, and help enterprises reduce costs and enhance efficiency. Cui Fengzhou, General Manager of the Semiconductor Division at Maxine Testing Mr. Cui Fengzhou, General Manager of the Semiconductor Division at Maxine Testing, delivered two keynote presentations at the main and breakout sessions of the conference: “Failure Analysis Based on the Industrial Hospital Model” and “Enhancing Reliability Through Electronic Component Failure Analysis.” Drawing on years of industry expertise, Mr. Cui provided an in-depth analysis of common causes of electronic component failures and effective strategies for enhancing reliability, offering valuable practical guidance to attendees. Maxim Testing introduced the Industrial Hospital service model for failure analysis at an academic conference for the first time, receiving unanimous acclaim from participants. Feng Xueliang, Expert in Electronic Process Failure Analysis at Meixin Testing Meanwhile, Mr. Feng Xueliang, an expert in electronic process failure analysis at Meixin Testing, delivered a keynote presentation titled “From Soldering Defects to System Failures: Typical Failure Mechanisms and Case Studies in PCBA.” Through practical case studies, he elaborated in detail how soldering defects can trigger system-level failures, offering profound insights for industry peers. Wang Dong, Deputy Head of the Process Technology Expert Group at AVIC Computing Institute Mr. Wang Dong, Deputy Head of the Process Technology Expert Group at AVIC Computing Institute, presented “Root Cause Analysis of Failure in Avionics Assembly Processes and Strategies for Reliability Enhancement,” offering a systematic solution for improving reliability in the avionics field. Researcher Wu Yeqing of Redi Aviation Technology (Beijing) Co., Ltd. Researcher Wu Yeqing of Redi Aviation Technology (Beijing) Co., Ltd. focuses on “Electronic Component Selection and Replacement Analysis Technology,” providing the industry with precise guidance for component selection and replacement. Chen Rui, Chief Process Engineer at Beijing Aerospace Microelectronics Technology Co., Ltd. Mr. Chen Rui, Chief Process Engineer at Beijing Aerospace Microelectronics Technology Co., Ltd., presented “Analysis of Electronic Component Failure Cases.” Through real-world examples, he revealed failure mechanisms, providing crucial reference material for the industry. Maxin Testing not only co-hosted this academic conference, presenting a spectacular academic feast, but also co-organized the National Failure Analysis Finals. This initiative established an efficient platform for deep integration of industry, academia, research, and application within the failure analysis field, dedicated to cultivating talent in China's failure analysis sector. Moving forward, Meixin Testing will remain committed to delivering more professional, efficient, and reliable failure analysis solutions for enterprises. We will actively collaborate with universities and research institutions to jointly enhance product quality and safety reliability in manufacturing, thereby contributing to the industry's high-quality development.