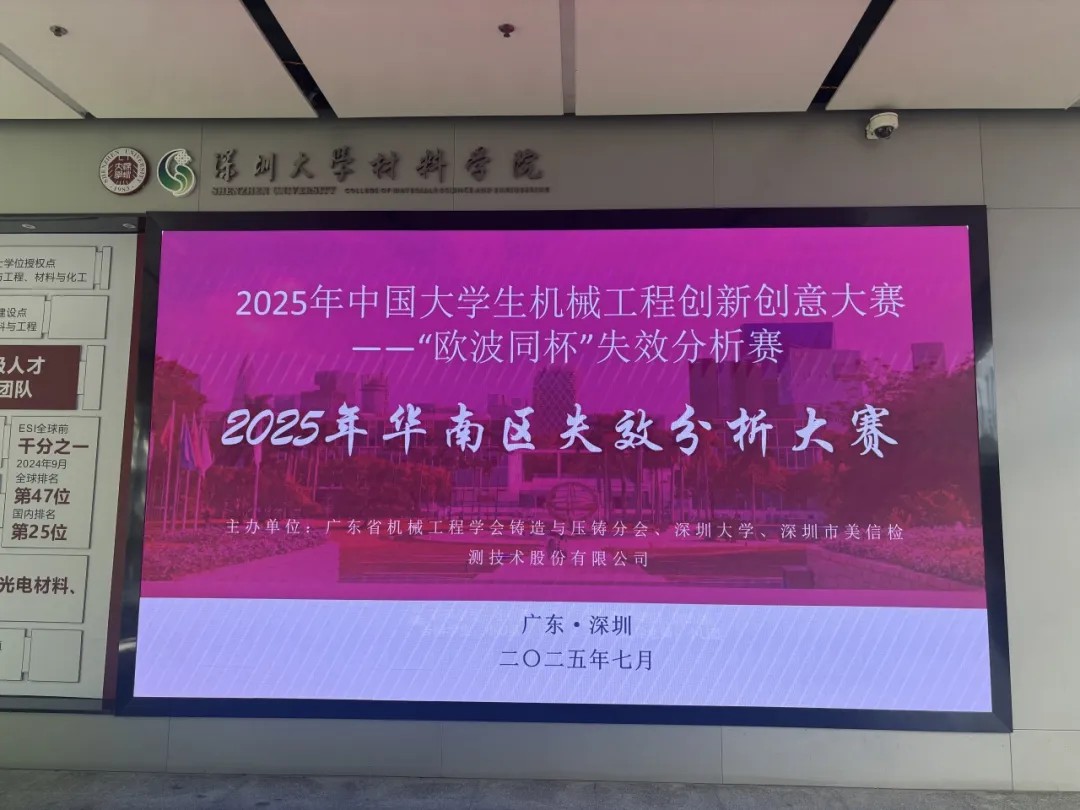

The 2025 China College Students Mechanical Engineering Innovation and Creativity Competition - Failure Analysis Division South China Regional Competition successfully concluded at Shenzhen University on July 9.

Co-hosted by Shenzhen University, the Casting and Die-Casting Branch of the Guangdong Society of Mechanical Engineering, and Shenzhen Meixin Testing Technology Co., Ltd., the event attracted outstanding teams from universities across Guangdong, Guangxi, Hainan, Fujian, and other provinces.

Centered on the theme “Failure Analysis Enhances Product Safety, Quality, and Reliability,” the event featured both Innovation and Creativity tracks for undergraduate and graduate students, showcasing the outstanding capabilities and innovative spirit of South China's students in the field of failure analysis.

High-level competition, balancing innovation and creativity Participating teams conducted in-depth research on failure cases across mechanical, materials, electronics, and chemical engineering fields, submitting entries that combined academic rigor with practical value. Innovation track teams presented independently researched, unpublished cases, while creativity track teams proposed novel solutions through reinterpretation of publicly available cases. The regional competition was conducted online, where teams fully presented their research findings through 10-minute PowerPoint presentations followed by 5-minute Q&A sessions. Judges conducted comprehensive evaluations based on multiple dimensions including “problem description,” “analytical process,” “solution approach,” and “innovativeness.”

Award Winners Announced, Outstanding Teams Emerge Following rigorous evaluation, the competition has selected first, second, and third prize winners, along with merit awards, with a total award rate reaching 60%. Selected outstanding teams will advance to the national finals to compete alongside contestants from other regions.

The South China Regional Finals have advanced 30% of the top teams to the National Finals, where they will compete for the championship at Beihang University's Shahu Campus from August 9 to 12. We look forward to these teams achieving even greater success on the national stage!

The successful hosting of this competition would not have been possible without the strong support from universities, expert judges, and partners. As one of the organizing entities, Shenzhen Meixin Testing Technology Co., Ltd. remains committed to advancing failure analysis technology and cultivating talent. We will continue to contribute to innovation within the industry in the years ahead. Congratulations once again to all the winning teams! See you in Beijing for the National Finals!