Focusing on

key issues such as enhancing automotive electronics reliability, failure analysis, and cutting-edge technologies

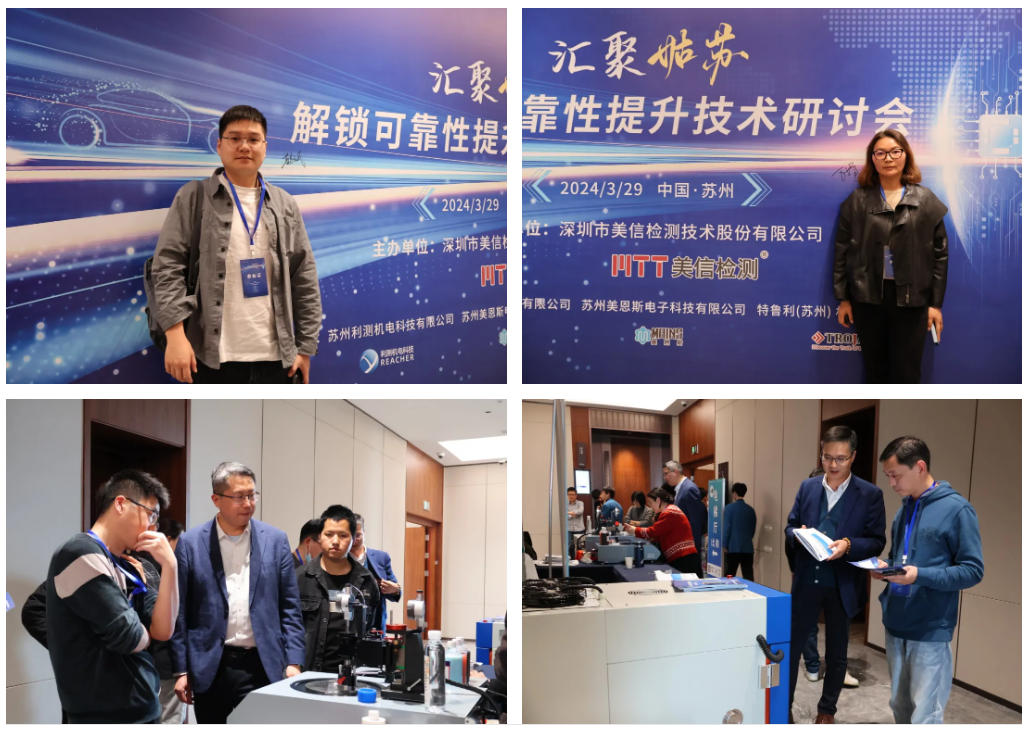

March 29, 2024

This groundbreaking

Technical Seminar on Enhancing Automotive Electronics Reliability

held at the Suzhou International Conference Hotel

unfolded as a spectacular feast of intellectual exchange

and dynamic collision of ideas.

The Automotive Electronics Reliability Enhancement Technology Seminar, hosted by Shenzhen Meixin Testing Technology Co., Ltd. (Meixin Testing), brings together top domestic technical experts, industry elites, representatives from research institutes, and professionals from electronics manufacturing, aerospace, and other sectors. Participants will collectively explore new technologies and development trends for enhancing automotive electronics reliability. This conference aims to foster the exchange of innovative ideas, assist enterprises in improving their quality assessment capabilities, gain a firm grasp of current product quality status, and provide effective solutions.

This exchange seminar

invited four industry professionals

to comprehensively, deeply, and from multiple angles

“unlock the secrets to enhancing reliability.”

Cui Fengzhou, an integrated circuit expert at Meixin Testing, shared insights into typical failure modes of integrated circuits in the electronics manufacturing field through a detailed introduction to ICs. He also analyzed key steps in IC reliability testing, providing a comprehensive and clear explanation of IC reliability evaluation.

Liu Jinwei, Reliability Expert at Geely Auto, focused on reliability testing and failure analysis of automotive electronic and electrical hardware. Through practical case studies, he highlighted the distinctions between DVP testing and comprehensive stress reliability testing. He further outlined the three levels of reliability testing: the surface application layer, the architectural layer, and the microscopic principle layer. Additionally, he provided forward-looking insights into the future development trends of reliability in the automotive industry.

Peng Jing, a physical analysis expert at Meixin Testing, highlighted the critical importance of cleanliness control for automotive electronic components. He engaged in discussions with attendees on solutions to further enhance cleanliness management and control, thereby promoting high-quality development within the automotive electronics industry.

Xue Guanghui, the most influential hands-on expert in PCBA across mainland China, delivered a detailed and vivid comprehensive analysis of PCBA failure analysis methods and applications. This included key elements for formulating failure analysis plans, fundamental skill requirements for failure analysis, process monitoring during failure analysis, and case studies of failure analysis. Packed with practical insights, the session proved immensely valuable to attendees.

This exchange seminar focused on specific topics, broadened perspectives, and fostered innovative thinking.

Everyone enthusiastically shared their questions with the experts, sparking lively discussions. The atmosphere was vibrant, achieving the desired outcome.

Now is the time to ride the waves and break through the wind, To hoist our sails and set forth on new voyages. Since its founding in 2012, Meixin Testing has provided clients with full-lifecycle technical services spanning product R&D, manufacturing, and after-sales support. As our credibility and social influence have steadily grown, we have delivered solutions to over 10,000 enterprises.

Future Meixin Testing will continuously enhance its service awareness and capabilities, further expand communication platforms, and deepen collaborative service approaches, striving to establish an industrial hospital service model.

Integrity, Expertise, Service, Teamwork, Mutual Success

Official Website: www.mttlab.com

Hotline: 400-850-4050

Email: marketing@mttlab.com

Providing Material Testing, Failure Analysis, and Technical Consulting Services

Long press to scan the QR code and follow us