On the afternoon of August 22, under bright sunshine, the “Chip Intelligence Gathering” technical salon hosted by Shenzhen Meixin Testing Technology Co., Ltd. (hereinafter referred to as Meixin Testing) was successfully held. The event attracted numerous experts, scholars, and corporate representatives from the semiconductor field to jointly explore the latest advancements and future trends in semiconductor analysis technology.

At this “Chip Intelligence Gathering” technical salon, Maxine Testing aims to create a platform for sparking new ideas, fostering in-depth dialogue, and sharing knowledge. We strive to help enterprises strengthen their core capabilities in quality assessment and achieve precise control over product quality.

The grand opening of this “Chip Intelligence Gathering” technical salon featured You Qiqian, Head of the Laboratory at Maxim Testing's Semiconductor Division. Drawing on over a decade of deep expertise in component testing and analysis, he gradually unveiled the mysteries of “FIB/TEM Applications in the Semiconductor Field.”

With his unique insights and vivid language, Mr. You transformed the complex intricacies of FIB and TEM into an engaging feast of knowledge.

Immediately following, Chief Engineer Cui Fengzhou of the Semiconductor Division took the stage. Drawing upon his exceptional technical expertise and extensive industry experience, he delivered an authoritative presentation titled “Analyzing Precise Defect Localization Solutions.”

Through vivid case studies and in-depth analysis, Chief Engineer Cui elucidated the precise defect localization technologies employed in semiconductor manufacturing. His insights provided invaluable strategies and perspectives for enhancing product quality.

Subsequently, Tan Jufang, Head of the DPA Group within the Semiconductor Division, presented the topic “DPA and Authenticity Verification.” In this era of rampant counterfeit and substandard products, Engineer Tan guided attendees through developing a keen eye for identifying genuine components. This approach enhances incoming material quality control, ultimately elevating overall product quality.

Finally, Zhang Yu, a reliability engineer from the Semiconductor Business Unit, presented the core principles of “Semiconductor Reliability Assessment Methods.”

He provided a detailed overview of the scientific processes and methodologies for semiconductor reliability assessment, offering robust support for developing more reliable and stable semiconductor products.

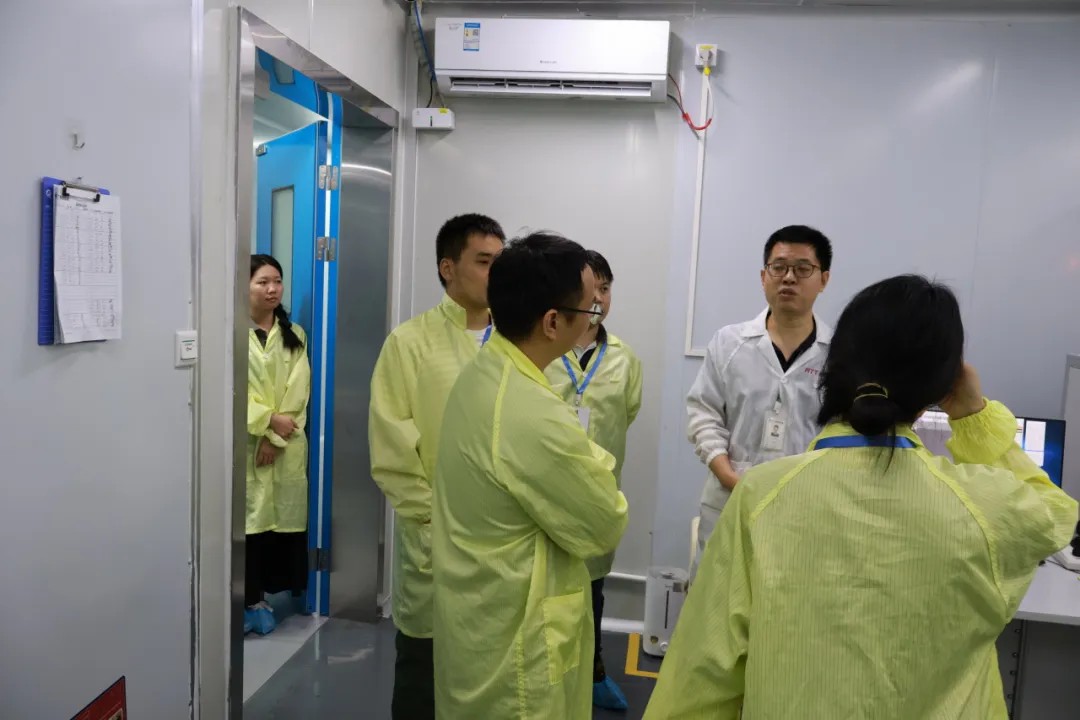

Following the conclusion of the event, participants were personally guided by professional engineers on an in-depth tour of the Meixin Testing Shenzhen Integrated Circuit Reliability Analysis and Testing Public Service Platform Laboratory. They gained close-up access to advanced experimental equipment and testing environments. Attendees entered Meixin Testing's semiconductor laboratory and frontline R&D innovation facilities, observing firsthand the operational standards and procedures followed by professional engineers.

The successful hosting of this “Chip Intelligence Gathering” technical salon showcases Meixin Testing's technical prowess and deep industry expertise in semiconductor failure analysis. As a model national high-tech enterprise, Meixin Testing has dedicated twelve years to meticulous refinement. Leveraging its professional expertise and exceptional service quality, the company has successfully assisted thousands of enterprises in overcoming tens of thousands of complex failure analysis challenges, earning widespread acclaim and deep trust within the industry.

We specialize in delivering customized, high-efficiency solutions. Leveraging our robust professional team and precision cutting-edge testing equipment, Meixin Testing can accurately and swiftly respond to diverse product quality enhancement needs. We have not only significantly shortened testing cycles but also, through deep insight into client requirements, tailored a series of efficient, precise solutions that exceed customer expectations. We are committed to being a steadfast partner and reliable support for enterprises pursuing quality excellence.

Looking ahead, we are filled with anticipation and look forward to reconnecting with you!

Integrity, Expertise, Service, Teamwork, Mutual Success

Official Website: www.mttlab.com

Hotline: 400-850-4050

Email: marketing@mttlab.com

Providing Material Testing, Failure Analysis, and Technical Consulting Services

Long press to scan the QR code and follow us