On March 20, 2025, the “Electronic Component Failure Analysis Technology Salon,” hosted by Shenzhen Meixin Testing Technology Co., Ltd. (hereinafter referred to as “Meixin Testing”), was successfully held at Meixin Testing in Shenzhen. Centered on the core theme of “electronic product failure,” the event brought together industry experts, scholars, and corporate representatives. Through diverse formats including keynote speeches, case studies, and roundtable discussions, participants engaged in in-depth exploration of the failure mechanisms and solutions for electronic products.

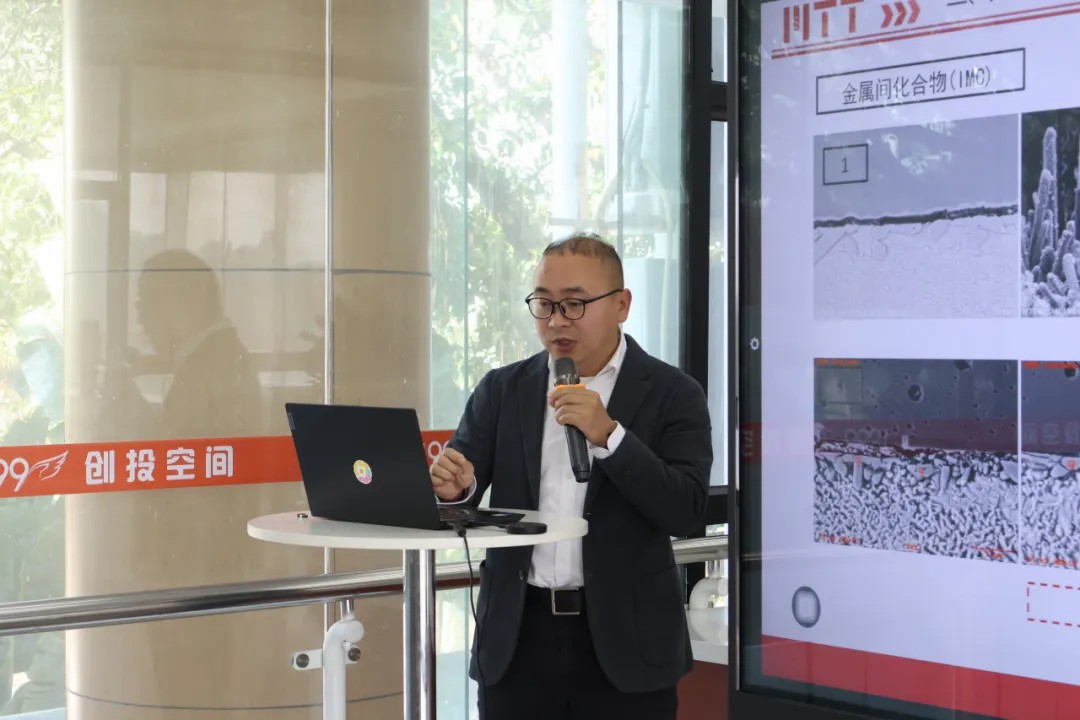

Cutting-Edge Technology Insights: The Scientific Key to Solving Failure Challenges The event featured special guest speakers Mr. You Qiqian, Head of the Failure Analysis Project Team at the Semiconductor Division of Meixin Testing, and Mr. Feng Xueliang, Failure Analysis Engineer specializing in electronic processes. Drawing on years of hands-on experience, the two experts systematically analyzed typical failure modes and root cause analysis methods for electronic components and PCBs/PCBA assemblies. Feng Xueliang Failure Analysis Engineer, Electronic Processes Professor Feng Xueliang specializes in in-depth analysis of failure issues related to electronic manufacturing processes, including ENIG black pad defects, poor solderability on plated-through holes, fatigue cracking of solder joints, and CAF-related failures. Through cross-section analysis, SEM observation, and thermal imaging techniques, he successfully resolved complex cases such as grain boundary fractures in BGA solder joints on mobile phone motherboards and dendritic short circuits in automotive fuel gauge LEDs. These achievements not only demonstrate Maxin Testing's profound expertise in soldering process evaluation and material reliability verification but also provide valuable insights and methodologies for enterprises addressing similar challenges.

You Qiquan Semiconductor Division Failure Analysis Engineer Professor You Qiquan focused on core components such as integrated circuits, transistors, and resistors/capacitors to elaborate on their failure mechanisms. Through typical cases like moisture-sensitive stratification, burnout, and sulfidation corrosion, he demonstrated failure analysis workflows and the application of advanced equipment. For instance, addressing complex issues like cracked automotive LED chips and blacked-out camera modules, high-resolution 3D X-ray machines, Thermal EMMI, and FIB equipment were employed to precisely locate microscopic failure points such as microcracks and open-circuit defects. Combined with electrical and material analysis, this approach rapidly pinpointed root causes. This suite of failure analysis techniques provides robust support for enterprises transitioning from reactive troubleshooting to proactive prevention in quality control. Driven by expertise to fuel innovation, Delivering value through service excellence. This technical salon not only provided attendees with a cutting-edge platform for exchanging technological insights but also highlighted Maxim Testing's core values of integrity, professionalism, service, teamwork, and mutual success. Moving forward, the company will continue to deepen its expertise in failure analysis, focusing on technological innovation and standardized services. Leveraging its professional capabilities, Maxim Testing will empower enterprises to enhance product reliability and drive high-quality development in the electronics manufacturing industry.