On April 25, 2025, the “2025 Unlocking the Secrets to Reliability Enhancement Technology Seminar,” hosted by Shenzhen Meixin Testing Technology Co., Ltd. (abbreviated as Meixin Testing) and co-organized by Guoke Industrial Software (Suzhou) Technology Co., Ltd., was successfully held in Suzhou. The conference focused on cutting-edge developments and practical applications in automotive electronics reliability technology, drawing numerous industry experts, corporate representatives, and technical elites to explore innovative pathways and industry trends in automotive reliability technology.

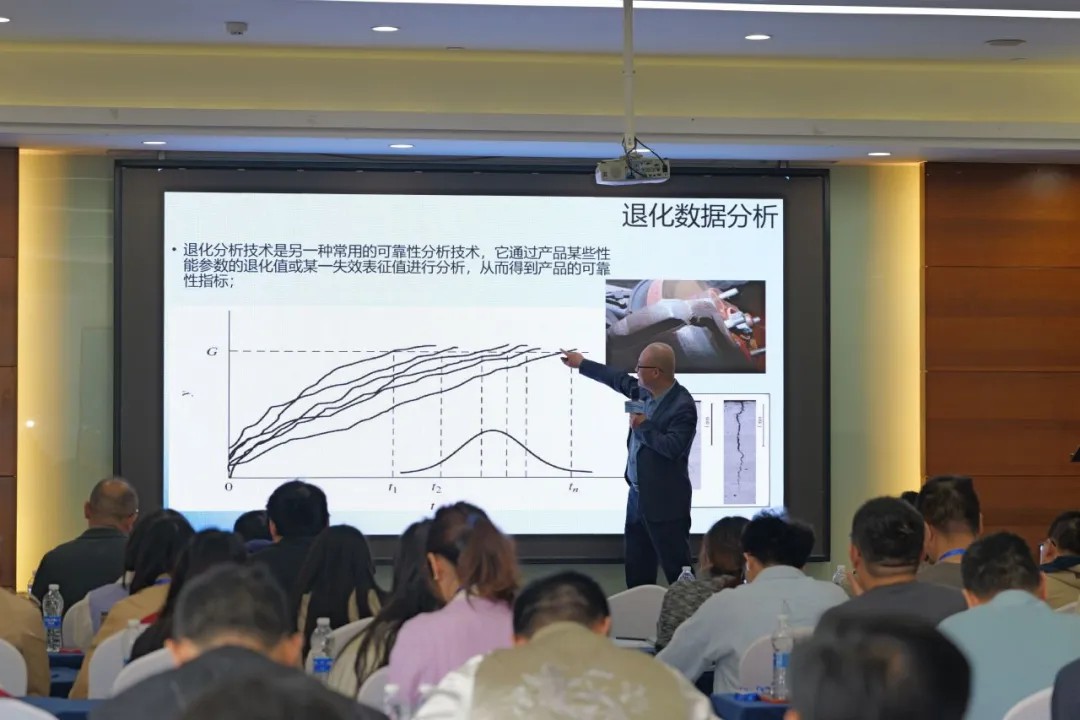

Practical Applications of Reliability Data Analysis Chen Yunbin, General Manager of Guoke Software Mr. Chen Yunbin delved into the critical role of reliability data analysis in the development, optimization, and reliability enhancement of automotive electronic products. He elaborated on how data analysis techniques can predict product failures, optimize designs, and reduce warranty costs. Through multiple real-world case studies, he demonstrated the significance of data analysis in improving the full-lifecycle reliability of automotive electronic products.

A Brief Analysis of Failure Analysis Patterns and Methods for Common Electronic Components in New Energy Vehicles Dr. Liu Qizheng Dr. Liu provided an in-depth explanation of failure analysis patterns and methods for common electronic components in new energy vehicles. He thoroughly analyzed the failure mechanisms of key components such as IGBTs, introduced the fundamental approaches and commonly used tools for electrical failure analysis, and demonstrated the application of non-destructive and destructive testing techniques.

Failure Mechanisms and Case Studies of Automotive Electronic PCBs/PCBA Feng Xueliang, Electronic Process Expert at Maxin Testing Engineer Feng provided a detailed presentation on failure mechanisms and multiple typical cases involving automotive electronic PCBs and PCBA assemblies. He delved into the soldering mechanisms of soft solder joints, revealing common failure causes such as ENIG black solder pads and poor tinning on electroless nickel-plated boards. Additionally, he introduced failure modes including solder joint fatigue and dendrite growth on board surfaces. Through concrete case studies, Engineer Feng offered attendees valuable insights into failure analysis and preventive countermeasures.

Reliability Design and Potential Failure Analysis of New Energy Vehicle's Three Electrical Systems Liu Jinwei, Reliability Expert at Geely Auto

By examining potential failure modes in new energy vehicle's three electrical systems, Mr. Liu Jinwei proposes a dual-assurance strategy based on design optimization and quality control.

Wei Yujie, a dedicated engineer at Meixin Testing, focused on testing battery packs for new energy vehicles. He not only provided an in-depth introduction to the composition and key components of battery packs but also comprehensively analyzed common testing standards and projects, including temperature testing, mechanical testing, and external environment simulation testing. Additionally, he shared multiple battery pack testing case studies, offering practical experience to enhance battery pack stability for the industry. Subsequently, Meixin Testing Engineer Wang Jie addressed standardization practices in connector testing. Approaching the subject from multiple dimensions—including electrical performance, mechanical characteristics, vibration/shock, and environmental testing—she combined typical test cases to meticulously dissect the full-process validation methodology for automotive-grade connectors. This provided a reusable technical pathway for optimizing connector reliability.

With the conclusion of the discussion session, the “2025 Unlocking Reliability Enhancement Cryptography Technology Seminar” successfully drew to a close. Shenzhen Meixin Testing Technology Co., Ltd. extends its sincere gratitude to the participating experts, partners, and all attendees for their valuable contributions. By deeply integrating technical standards with practical case studies, this conference has provided robust momentum for innovative breakthroughs in automotive electronics reliability technology. It has not only established a platform for industry-wide technical exchange and collaborative innovation but also injected fresh vitality into the field of automotive electronics reliability through systematic solutions.