《In the previous article》In , we have established a knowledge framework for the properties and applications of metal materials and sorted out the core steps of scientific material selection. However, the theory needs to be tested in practice.

This article will focus on the actual combat link: how to use advanced detection technology to provide reliable data support for material selection decisions? How to balance performance and cost in a project? And through real cases, the consequences and solutions of improper material selection are revealed.

Is the performance standard? Key Indicators and Testing Technologies

Composition

analysis: Through spectroscopy and chemical analysis, determine whether

the content of various elements in the material meets the requirements

of the grade composition limit. 2,

mechanical properties: including tensile strength, hardness, toughness,

ductility, etc., through tensile testing, impact test evaluation. 3,

electrical conductivity, thermal conductivity: directly affect the heat

dissipation design, such as mobile phone shell need to take into

account the thermal and electromagnetic shielding. Chemical

stability: through salt spray test, acid and alkali soaking simulation

of the actual use environment (such as insulation cups need to be

resistant to water, tea, coffee corrosion). Fatigue

performance: Evaluate the life of the material under the cycle stress

and the key performance indicators of long-term safe service (such as

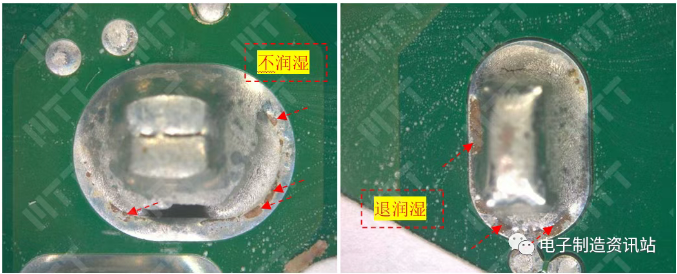

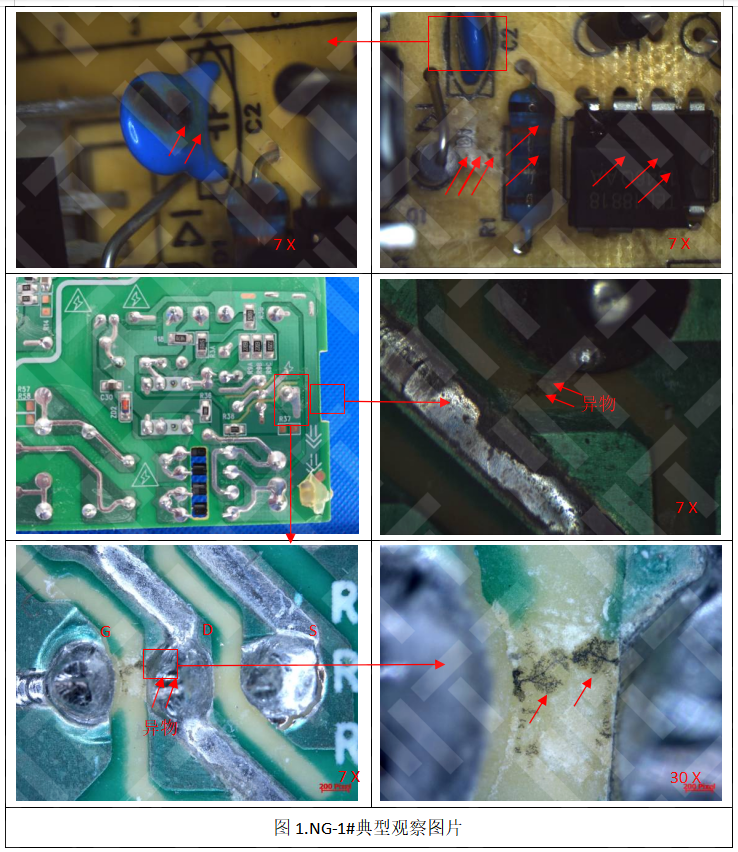

car chassis parts). Microstructure: The metallographic microscope observes the size and distribution of grain and determines the process defects.

Ingredient analysis instruments & testing technology introduction

Laboratory commonly used metal material detection methods and their applicable scenarios:

Technical comparison: OES and XRF are suitable for rapid field inspection, but XRF has superior non-destructive properties; ICP-OES/MS has higher precision, but requires complex pre-processing, and is suitable for laboratory precision analysis.

How to balance performance and cost?

Taking the thermos cup as an example, the selection of materials needs to be considered comprehensively: Safety: Food grade stainless steel (such as 316) needs to meet the GB 9684 standard austenitic stainless steel. Corrosion

resistance: 316 stainless steel can withstand acidic beverages (such as

lemon juice) for a long time because of molybdenum. Thermal

conductivity: The double-layer vacuum structure can reduce thermal

conductivity, but the thermal conductivity of the material itself needs

to be moderate. Cost: 304 stainless steel cost-effective, 316 is suitable for high-end demand.

How to balance performance and cost?

A

smart watch shell: use titanium alloy (lightweight + sweat corrosion

resistance), through XRF to verify the uniformity of the coating. New

energy vehicle battery housing: the use of aluminum alloy (lightweight +

excellent heat dissipation), through the salt spray test to ensure

environmental corrosion resistance. In

coastal equipment, 304 bolts are stress-corrosive cracking, and there

is no Mo (PREN=19) in 304, which cannot resist chloride ion erosion →

316 containing Mo (PREN=25). Copper

connector plug force attenuation, phosphorus bronze contact after high

temperature and high humidity elasticity decline; through component

analysis found that the Sn content is insufficient (<5%),

insufficient aging, and then recommended to increase Sn to 6-8% (such as

C5191). Aluminum

alloy shell intergranular corrosion, the product in the anodized after

the corrosion pattern; detection component analysis Fe impurity

exceeding the standard (>0.5%) to form the Al3Fe cathode phase,

accelerate local corrosion → control Fe <0.2%. The

selection of metal materials is a subtle art that combines material

science, testing technology and engineering experience. From accurate

component analysis to rigorous performance verification, rigorous data

support is required at every step.

Everyone, here’s a good gift waiting for you! “Down with a little trick.” Under the premise of ensuring core functions, the most effective metal material you have used is the "cost reduction" method. F. Other methods 在Share your usual tricks in (select letters) And tell the reason. We will be in the comments section on July 28th. Choose three fans. Give the following gift (one choice) 1! Failure analysis case book Household tool kit

A. Search for domestic alternatives (performance standards)

B. Optimized design to reduce material usage

C. Choose a lower-cost alloy grade (such as 6 series aluminum instead of 7 series)

D. Improved process to reduce scrap rates

E. There is no particularly good way for the time being.