A FPC found that some locations appear shallow phenomenon, NG samples on the side and in the middle of the shallow phenomenon, the next article will be through the systematic failure analysis, aimed at finding the root cause of the FPC shallow.

1. Optical analysis The

shallow and normal position of the NG sample marked by the shallow and

normal position of the NG sample are analyzed to be shallow on the left

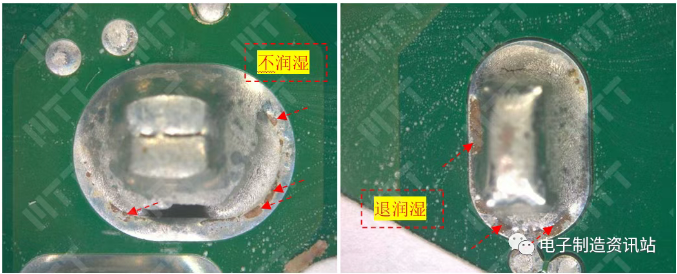

and middle of the NG sample. 2. morphological analysis Open

the FPC gold finger and glass surface, the shallow position for

observation found that the ACF glue mainly residue in the glass surface,

FPC edge, gold finger and gold finger between the denser particles, FPC

surface has more black spots, glass surface ACF adhesive surface has

more density of larger particles. Conductive

particles obvious area ACF glued to the FPC surface and glass surface,

FPC surface no obvious black point, glass surface no obvious scattered

particles.

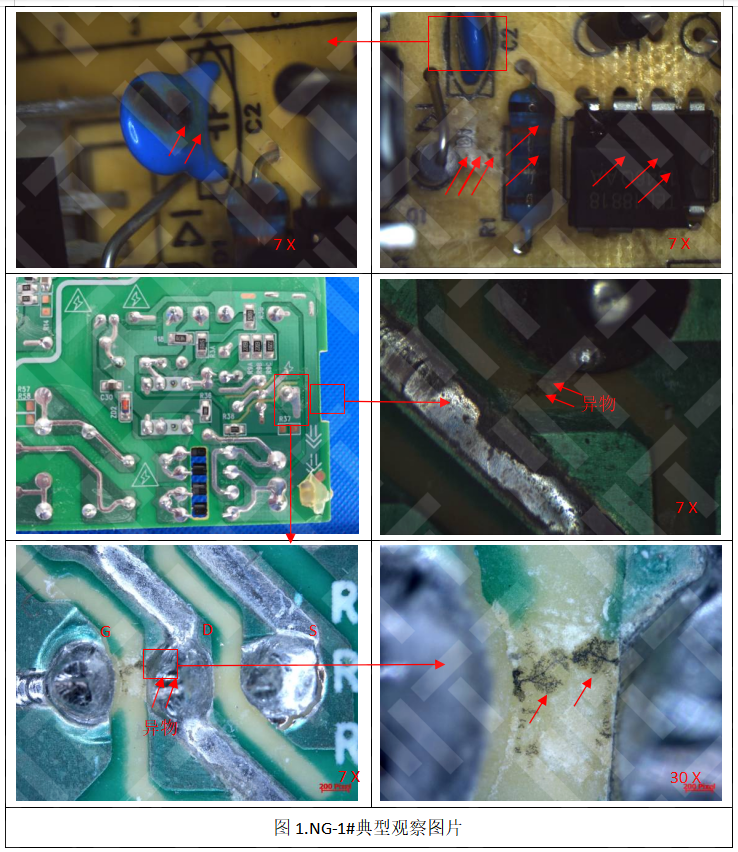

3. Sliced analysis The

shallow position and normal position of the NG sample are observed:

there is a layer of material on the surface of the FPC in the shallow

position, the two sides of the FPC are more serious, and the area with

thicker edge foreign objects has a layered phenomenon. There is no

obvious substance on the surface of the FPC in the normal position. 4. Elemental analysis For

elemental analysis of the shallow position of the NG sample sample, the

ACF glue surface particles contain Ni, Cu, Cl and other elements; the

slicing FPC surface material mainly contains Ni, Cu, Au, O, Cl and other

elements, mainly Ni, Cu corrosion products. 5. FTIR analysis From

the infrared spectator, it can be seen that the NG sample sample

shallow position and normal position, both of which are polyurethane, of

which 3410~3435cm-1 belongs to the N-H telescopic vibration absorption

peak of polyurethane; 1725~1735cm-1 belongs to the C=O telescopic

vibration absorption peak in polyurethane; the two absorb peak position

and strength are not significantly different, and there is no obvious

difference in curing degree as shown in Figure 6-1.

6. Analysis and Summary Sample of NG: From

the morphological analysis and slicing results, it can be seen that the

light position, the ACF glue is mainly glued to the glass surface, and

the normal position ACF glue is glued to both the FPC and the glass

surface; the shallow side position FPC is more dense particles (BSE

backscatter mode, the greater the density, the whiter the color), and

most of the elements embedded in the glue interior, combined with the

elements analysis results, the main elements of the particles are Ni,

Cu, Cl, O, K and other elements. The

mechanism of nickel and copper corrosion caused by Cl ions is mostly

electrochemical corrosion, which is caused by pitting, producing nickel

oxide, nickel hydroxide, copper oxide and so on. In summary, the following conclusions can be drawn: The

reason for the shallow FPC is that the FPC is corroded by the Cl

element, and the corrosion product overflows to the surface and inside

of the glue, causing shallow phenomena.

Good public service in August. "In this article, the FPC shallow phenomenon belongs to What kind of polymer material fails?” A Corrosion failure B Wear failure C Thermal aging failure 在Share your answers We will select three fans on August 18th. Give the following gift (one choice) 1! Failure analysis case book Beautiful wireless mouse