In today's popularization of smart phones, mobile phone reliability has become the focus of user attention. A high-reliability mobile phone can not only bring a smooth experience, but also do not fall off the chain at a critical moment. So, what factors affect the reliability of mobile phones? How to upgrade? Today, let’s take a closer look at it.

History of mobile phone development From simulation to intelligent leap The development of mobile phones can be said to be the evolution of a communication technology. From the big brother of to

the 5G mobile phone that now integrates ultra-high-speed transmission,

ultra-low latency, and large-scale connectivity, every technological

innovation has brought about a huge change in mobile phones. Big Brother

can only carry out voice business, and in the 2G era, mobile phones began to support SMS, MMS, and even can handle mail and web pages. In the 3G era, the combination of mobile phones and the Internet is more closely, and multimedia forms have begun to enrich. In the 4G era, the network connection is faster and more stable, and the rise of APP has made mobile phone functions more diverse. In the 5G era,

the deep integration of artificial intelligence technology with mobile

phone hardware and software has made mobile phones have unprecedented

intelligence, convenience and personalization capabilities.

Cell Phone Structure and Function Precision and Diversity Integration A mobile phone, seemingly simple, but the internal structure is complex.

From motherboards to batteries, from displays to cameras, every

component is carefully designed and manufactured. The function of the

mobile phone covers many aspects such as calling, surfing the Internet,

taking photos, and entertainment. Today, with the continuous advancement

of technology, the functions of mobile phones are still expanding, such

as health monitoring, mobile payment, etc., to make our lives more

convenient.

Mobile phone reliability test project Rigorous and comprehensive testing The

reliability of mobile phones is affected by a variety of factors, which

are carried out throughout the entire process of mobile phone research

and development, production and use. From the research and development stage, design defects are

one of the important factors affecting the reliability of mobile

phones. For example, the heat dissipation design is unreasonable, which

will cause the mobile phone to run for a long time or be in a high

temperature environment, and the heat cannot be dissipated in time,

resulting in a decline in the performance of the mobile phone, and even a

crash, restart and other issues. The structural design is not

reasonable, which may affect the assembly accuracy of the mobile phone

and the stability of the internal components, and increase the risk of

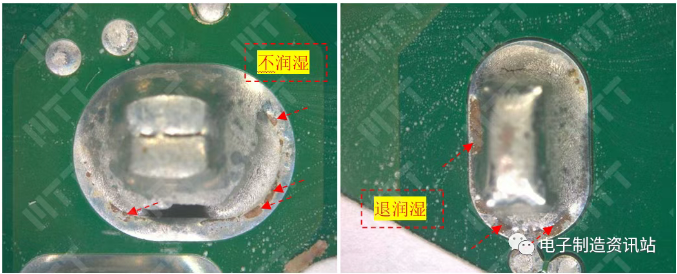

failure of the mobile phone. In the production process, hardware quality is the key.

The chip, as the "brain" of the mobile phone, the quality directly

determines the speed and stability of the mobile phone. If a low-quality

chip is used, it may cause the mobile phone to run stutter and crash

frequently. In addition, the quality of electronic components such as

capacitors, resistance, etc. can not be ignored, and the instability or

poor quality of their parameters may affect the normal work of the

circuit, which in turn leads to the failure of the mobile phone.

The use of the environment also

has an important impact on the reliability of mobile phones. In terms

of temperature, in a high temperature environment, the performance of

the mobile phone battery will decrease, the battery life will be

shortened, and the performance of electronic components may also be

affected, accelerating aging; in a low temperature environment, the

discharge capacity of the battery will be reduced, which may lead to the

automatic shutdown of the mobile phone. In terms of humidity, the high

humidity environment will make electronic components damp, causing short

circuits and other problems; low humidity environment may produce

static electricity, causing damage to mobile phones. In addition, dust

and vibration is also a factor that can not be ignored, dust into the

inside of the mobile phone may affect the heat dissipation and the

normal work of the circuit, and vibration may lead to loose and fall off

internal components of the mobile phone, causing poor contact.

What are mobile phone reliability improvement strategies? In

response to the above factors that affect the reliability of mobile

phones, we can adopt the following strategies to improve the reliability

of mobile phones. 在In the research and development stage,

we should pay attention to optimizing the design. Strengthen the heat

dissipation design, the use of efficient heat dissipation materials and

heat dissipation structure, such as heat sinks, heat pipes, etc., to

ensure that the mobile phone can maintain good heat dissipation

performance in various environments. At the same time, improve the

structural design, improve the assembly accuracy of the mobile phone and

the stability of internal components, and facilitate subsequent

maintenance and upgrading. In the production process,

the quality of the hardware should be strictly controlled. Choose

high-quality chip and electronic components suppliers to conduct

rigorous inspection and testing of raw materials to ensure that they

meet high standards. In the production process, increase multiple

inspection processes, and conduct comprehensive performance testing and

reliability testing of semi-finished products and finished products,

such as high temperature testing, low temperature testing, vibration

testing, etc., to detect and solve potential quality problems in a

timely manner. In the process of use, users should also pay attention to some things to protect the mobile phone

Avoid exposing your phone to high or low temperatures for a long time,

such as not placing your phone in a car that is directly sunny or

outside the cold. At the same time, pay attention to keep the phone dry,

to avoid the use of mobile phones in a humid environment. In addition,

regularly clean the dust inside the phone to avoid dust accumulation

affecting heat dissipation and normal operation of the circuit.

Witness the power of mobile phone reliability High and low temperature + soft pressure test after the display leakage

Mobile

phone reliability is a comprehensive concept, affected by a variety of

factors. By optimizing the design, strictly controlling the quality of

the hardware and the correct protection of the user during use, we can

effectively improve the reliability of the mobile phone and bring users a

more stable and smooth experience.

Note: The above picture is partly derived from external channels, and is only for learning communication and reference use.