— Read the siloxane test in one piece –

1 What is siloxane? Siloxane

is a class of silicone compounds containing Si-O-Si bonds, which are

widely used in rubber, detergent, polishing, adhesive, sealants and

other fields. Due to the environmental and health risks of certain

siloxanes, siloxanes have been regulated in many countries and regions

around the world.

2 How do relevant countries and regions control siloxane? EU REACH regulation: D4,

D5, D6, ocmethyltrisiloxane, demethyltetrasiloxane,

1,1,1,3,5,5,5,5-seven methyl-3-[(trimethylsilane)oxygen] trisiloxane is

classified as a substance of very concern (SVHC) and restricts its use

in some products. EU Cosmetics Regulation: D4

and D5 are prohibited for flushing cosmetics, with a limit of 0.1%. D6

is not explicitly restricted at this time, but a risk assessment is

required due to SVHC status. Stockholm

Convention: Due to the difficulty of degradation in the environment of

D4, D5 and D6, they are proposed to be included in the Stockholm

Convention POPs list. China:

China has not yet clearly defined the restrictions on D4, D5, and D6,

but the relevant industry standards are gradually improving.

3 Importance of Siloxane Testing Compliance requirements : With the increasing emphasis on environmental and health protection in the world national

regulations restrict and control siloxanes more and more strictly.

Through the siloxane test, enterprises can ensure that the product meets

the relevant regulatory requirements and avoids legal risks and

economic losses due to violations. Environmental protection:

Some siloxanes are persistent, bioaccumulative and toxic (PBT), which

may cause long-term harmful effects on aquatic environments, soil and

other ecosystems. Effectively control the residue of siloxane, help

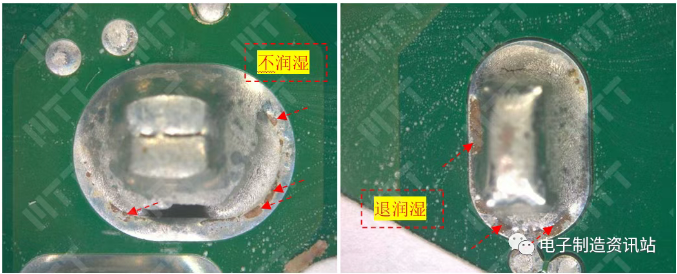

reduce environmental pollution, protect the ecological environment. 3 quality control: In the application of electronic products and other fields,

low molecular weight siloxane may affect the performance and quality of

the product, such as leading to electrical contact failure, optics

blurry fogging and other issues. By testing the siloxane content,

enterprises can optimize the production process, improve product

quality, enhance market competitiveness, and help enterprises establish a

good brand image.

4 How companies respond Enterprises

should deeply understand and comply with the EU REACH, cosmetics

regulations, the Stockholm Convention and Chinese industry standards,

evaluate the compliance of siloxane content in products, and ensure that

the siloxane content in the production process meets environmental and

health standards. Develop low-siloxane alternatives to reduce

environmental health risks through technological innovation. Continue to

pay attention to regulatory updates, adjust strategies in a timely

manner, reduce market risks, and promote sustainable development. Meixin

Testing can help companies investigate the presence of siloxane

substances in electrical and electronic products, components and raw

materials, provide professional solutions to avoid trade risks, and

promote sustainable development.

– U.S. News test recommendations –

With

the continuous updating and improvement of siloxane regulatory

regulations, enterprises need to pay close attention to relevant

developments, timely adjust test methods and production processes,

strengthen the detection and management of siloxane components, ensure

that products meet international and domestic regulatory requirements,

and avoid market risks due to violations.