After the aging test, a product found that the standby working current is abnormally increased. After detailed analysis, it was determined that the problem stemmed from the abnormality of the C6 capacitor (the capacitor of the specific position or function on the circuit board). In order to comprehensively and deeply explore the root cause of C6 capacitance failure, we have adopted a series of professional and systematic detection methods to carry out failure analysis work.

1. Appearance Check & X-ray Perspective The

surface of the failed capacitor capacitor does not find obvious cracks,

damage and other abnormal phenomena, excluding the failure caused by

factors such as external force impact of the capacitor. Use X-ray to

perform perspective inspection of the failure capacitor, and no obvious

structural abnormalities were found. 2. Electrical Parameter Testing The

failure capacitance resistance is less than 2kΩ, which is much less

than the unused capacitance resistance, indicating that the failure

capacitor has obvious leakage phenomenon, as shown in Table 1 of the

test result.

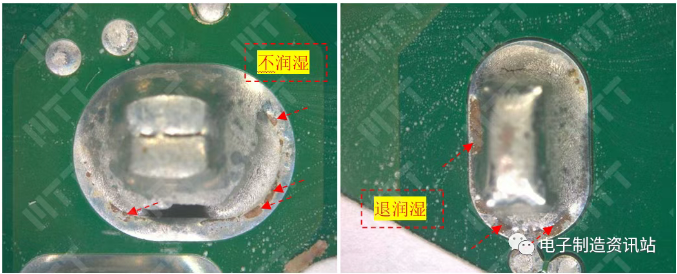

3. Thermal EMMI Hotspot Positioning It

was found that there are obvious abnormal highlights inside the failure

capacitor, and the highlights are mainly concentrated on the side of

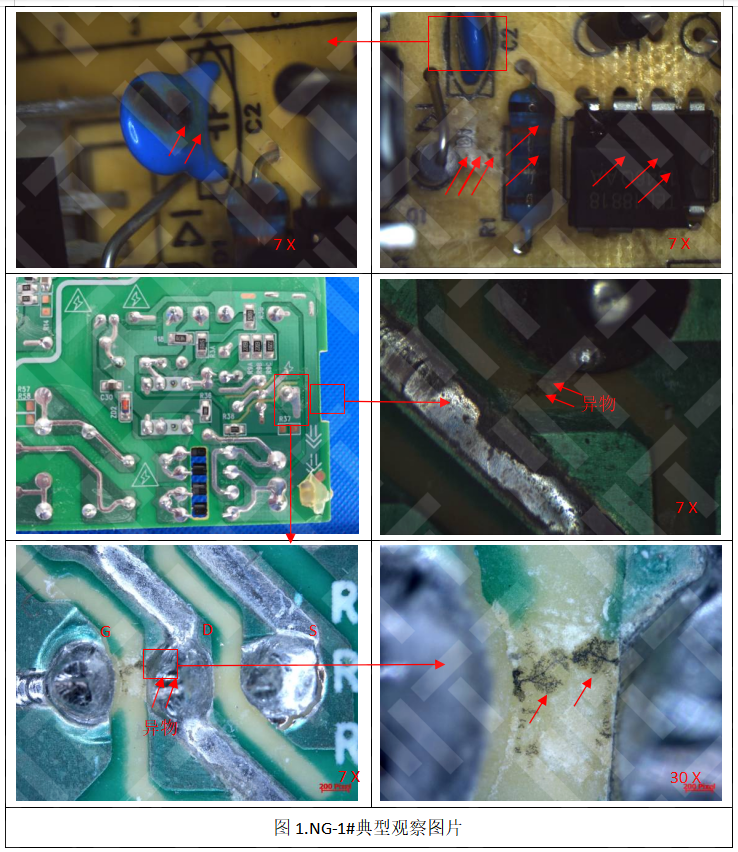

the electrode near the capacitance end. 4. Sliced analysis (1)

The position where the NG1 capacitor shows abnormal bright spots in the

hot spot has obvious cracks. Further grinding to the inner electrode is

revealed, and the crack is found to pass through the intersection of

the inner electrode, resulting in a short circuit or low resistance

channel between the upper and lower layers of the inner electrode.

Compared with the slicing of different locations, with the gradual

grinding to the inside of the capacitor, the cracks gradually become

smaller, indicating that the origin of the crack expansion should be

close to the outside of the capacitor. In addition, the microscopic

morphology observes that the cracks are fine, and no melting and burning

phenomenon is seen, which is presumed to be mechanical stress cracks. (2)

NG2, NG3 are found on the bottom side of the capacitor crack, and

extended to the inner electrode area to cause the capacitor layer

between the leakage short circuit, the position and hot spot abnormal

bright spot corresponding. The crack originated from the bottom surface

end electrode, and its angle and the bottom angle is close to 45 °,

which is a typical mechanical stress cracking morphology.

5. Material verification According

to the specification book, the three-point bending test is carried out

to confirm the appearance and electricality of the capacitor after the

experiment, and no obvious abnormalities are found. The slice analysis

of #1 and #2 capacitors has not been found to have obvious cracks,

medium layer holes and other defects. Therefore, the material can meet

its specifications. 6. Simulation experiment In

order to confirm whether the internal crack of the failure capacitor is

a mechanical stress crack, the #3 and #4 capacitors continue to bend

simulation test for the three-point bending, and the capacitance is

slicing analysis after the test. The

slicing results show that when the substrate is bent at 4mm, there are

obvious cracks in the interior of the #3 and #4 capacitors, and its

position originates from the end electrode position and is 45° with the

welding surface, which is basically the same as the internal cracking

morphology characteristics of the failure capacitor. Therefore, it is

inferred that the failure capacitor is subjected to a large external

stress, and then cracks occur internally. 7. Analysis and Summary Analysis:

The reason for the mechanical stress crack inside the capacitor is that

because the capacitive porcelain body is made of hard and brittle

ceramic material, this material is more sensitive to the stress

generated by the deformation of the single plate. When the capacitor is

subjected to additional stress, the crack will be generated at the

stress concentration point, as shown in Figure 15, if the device is

subjected to upward stress, the bottom weld end and the welding end of

the intersection at the junction of the welding end is the stress

concentration point, this position becomes a weak link, easy to produce a

crack with the welding end of 45° or "Y" font, and vice versa. Summary:

The main reason for the failure of the capacitor is that the cracks

that are extended to the inter-internetized electrode by external stress

are formed, resulting in a decrease in the resistance value caused by

the leakage channel. 8. Recommendation Check the external stress sources in the process of capacitance assembly, testing, etc.